Dielectric waveguide resonator, dielectric waveguide filter, and method of adjusting the characteristics thereof

a technology of dielectric filters and dielectric resonators, applied in the direction of resonators, gas discharge lamps, climate sustainability, etc., can solve the problems of difficult to connect a prism-shaped dielectric to a metallic case, and difficult to achieve the effect of adjusting the characteristics of the filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

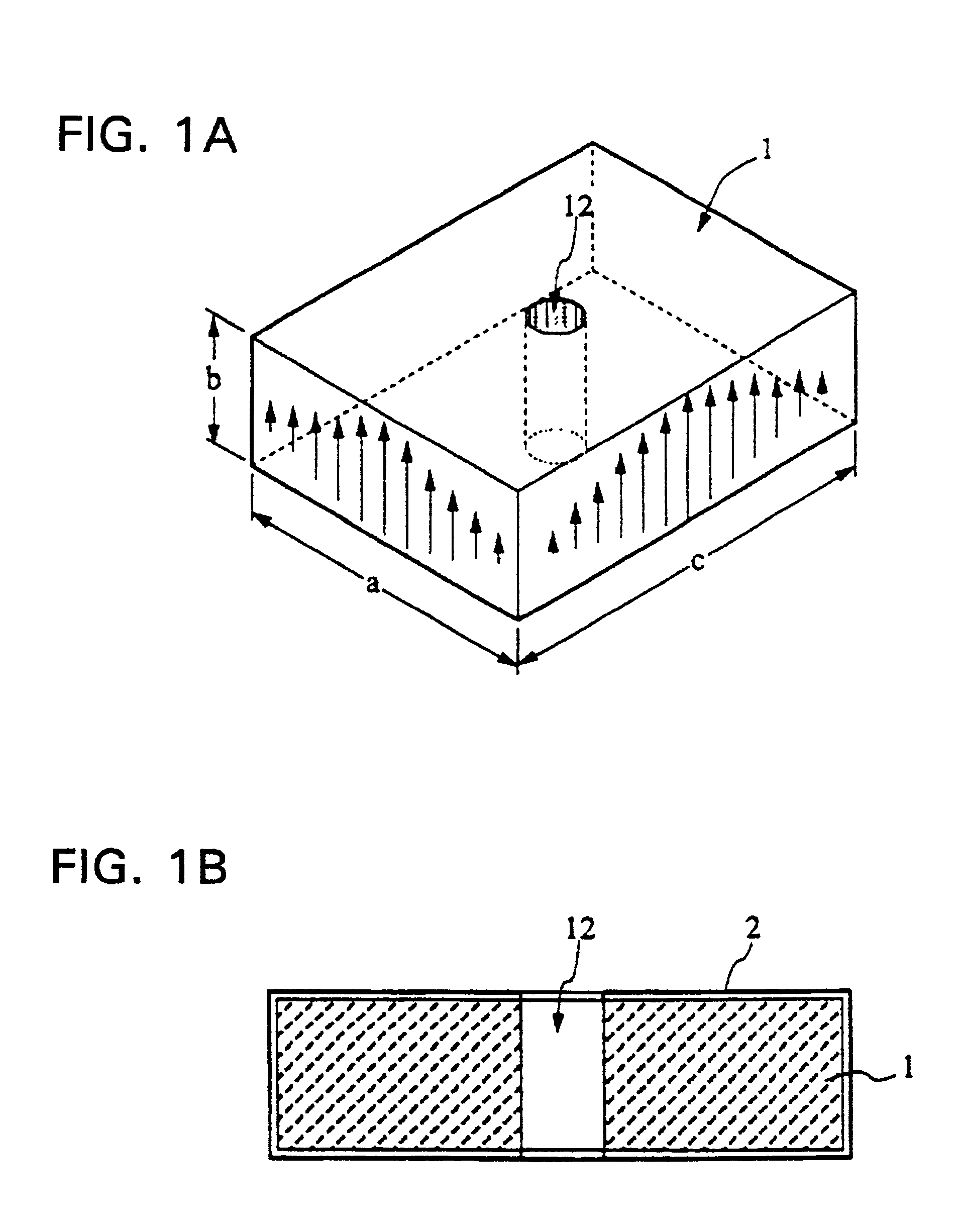

64. FIGS. 1A and 1B illustrate the construction of a dielectric waveguide resonator (hereinafter referred to simply as a dielectric resonator) according to a 1st embodiment of the present invention, wherein FIG. 1A is a perspective view illustrating its external appearance and FIG. 1B is a cross-sectional view thereof. Reference numeral 1 denotes a dielectric block in a substantially rectangular form. A circular through-hole 12 is formed in the center of the dielectric block 1 and a conducting film 2 is formed on the outer surface (six side faces) of the dielectric block 1. In FIG. 1A, the arrows drawn on the sides of the dielectric block 1 represent the projections of the electric field distribution inside the dielectric block 1 (in the central portion or near the central portion) onto the two sides of the dielectric block 1. The actual internal electric field distribution is similar to that shown in FIG. 31 wherein the energy of electric field in the vertical direction in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com