Condition analyzer

a condition analyzer and analyzer technology, applied in the field of condition analyzers, can solve problems such as the condition of the machine to deteriora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

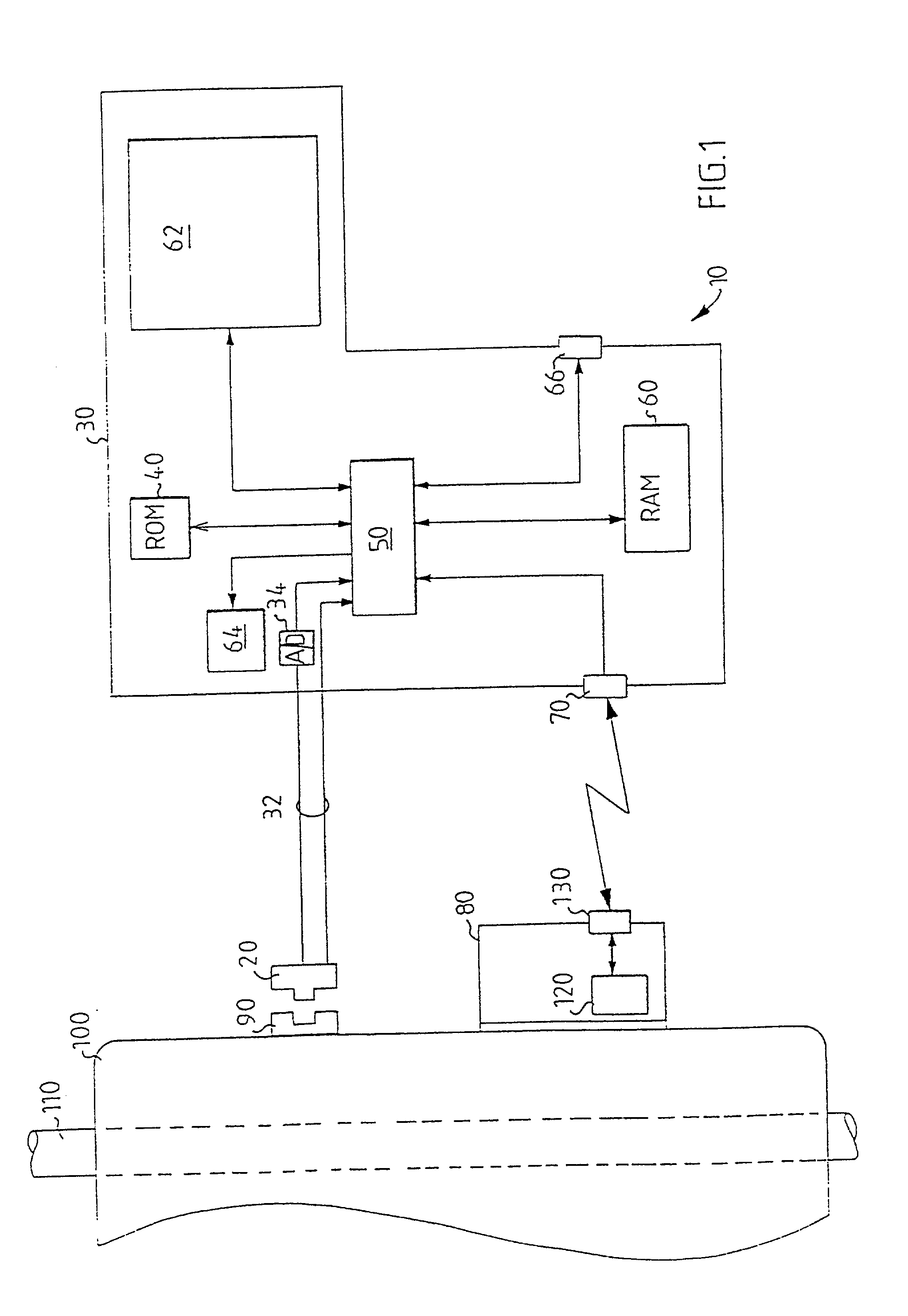

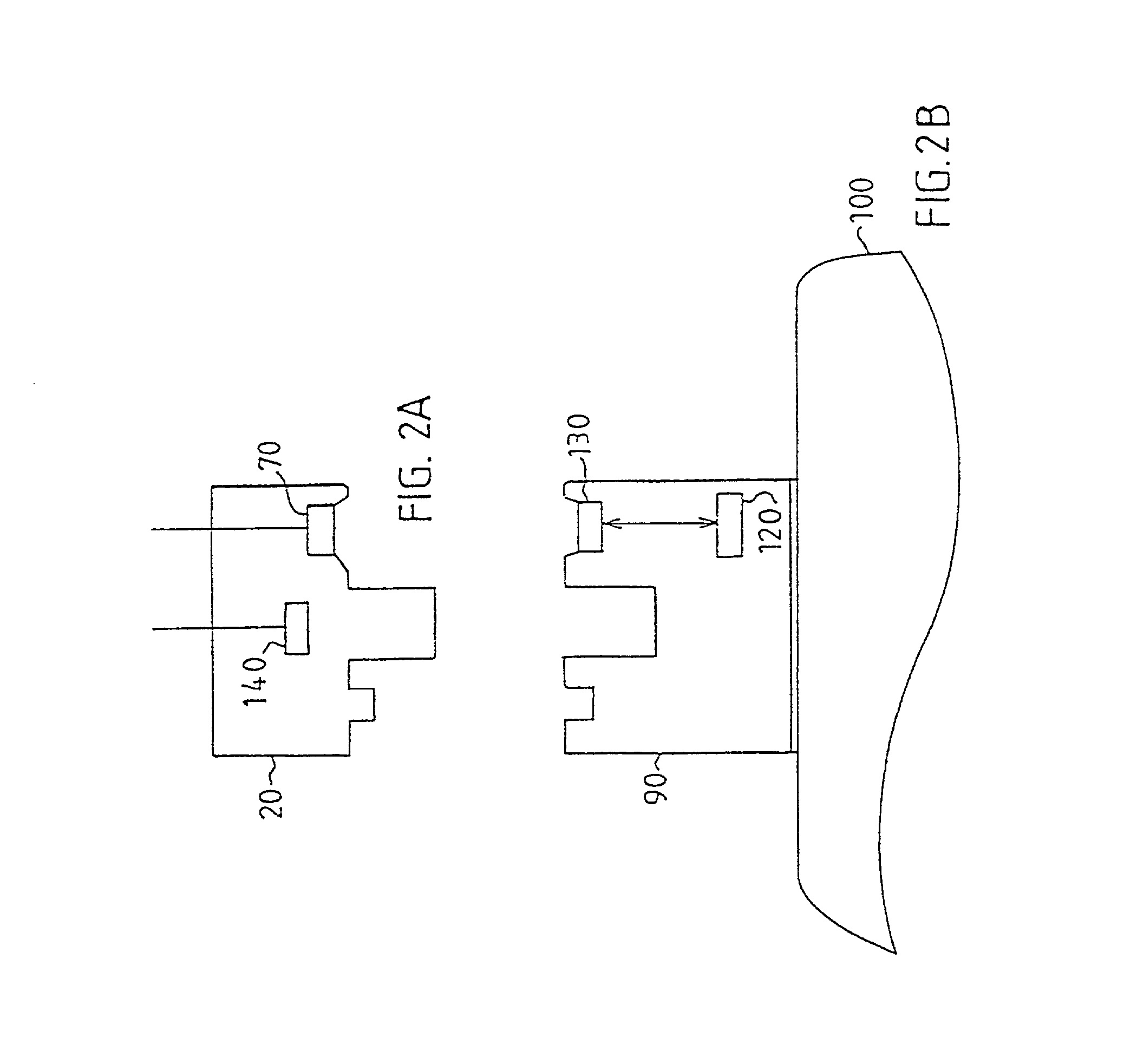

17. FIG. 1 shows a schematic block diagram of an embodiment of a condition analyzing system 10 according to the invention. The condition analyzing system comprises a sensor unit 20 for producing a measured value dependent on movement and, more precisely, dependent on vibrations.

18. The sensor unit 20 is connected to an analysis apparatus 30 via a conductor 32. The analysis apparatus 30 comprises a non-volatile memory 40, a microprocessor 50 and a read / write memory 60. A computer program is stored in the read memory 40, and by means of this computer program the function of the analysis apparatus 30 is controlled. When it is written below that the microprocessor 50 performs a certain function, it shall be understood that the microprocessor runs a certain part of the program which is stored in the memory 40.

19. The microprocessor 50 is connected to a display unit 62. By means of the display unit 62 a user of the condition analyzing system is informed of the condition of the current mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com