Material removing tool

a technology of material removal and tool, which is applied in the direction of metal sawing equipment, gear teeth, stone-like material working equipment, etc., can solve the problems of not being able to form precisely defined and not being suited to the making of accurate laterally limited and definable recesses or grooves in workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

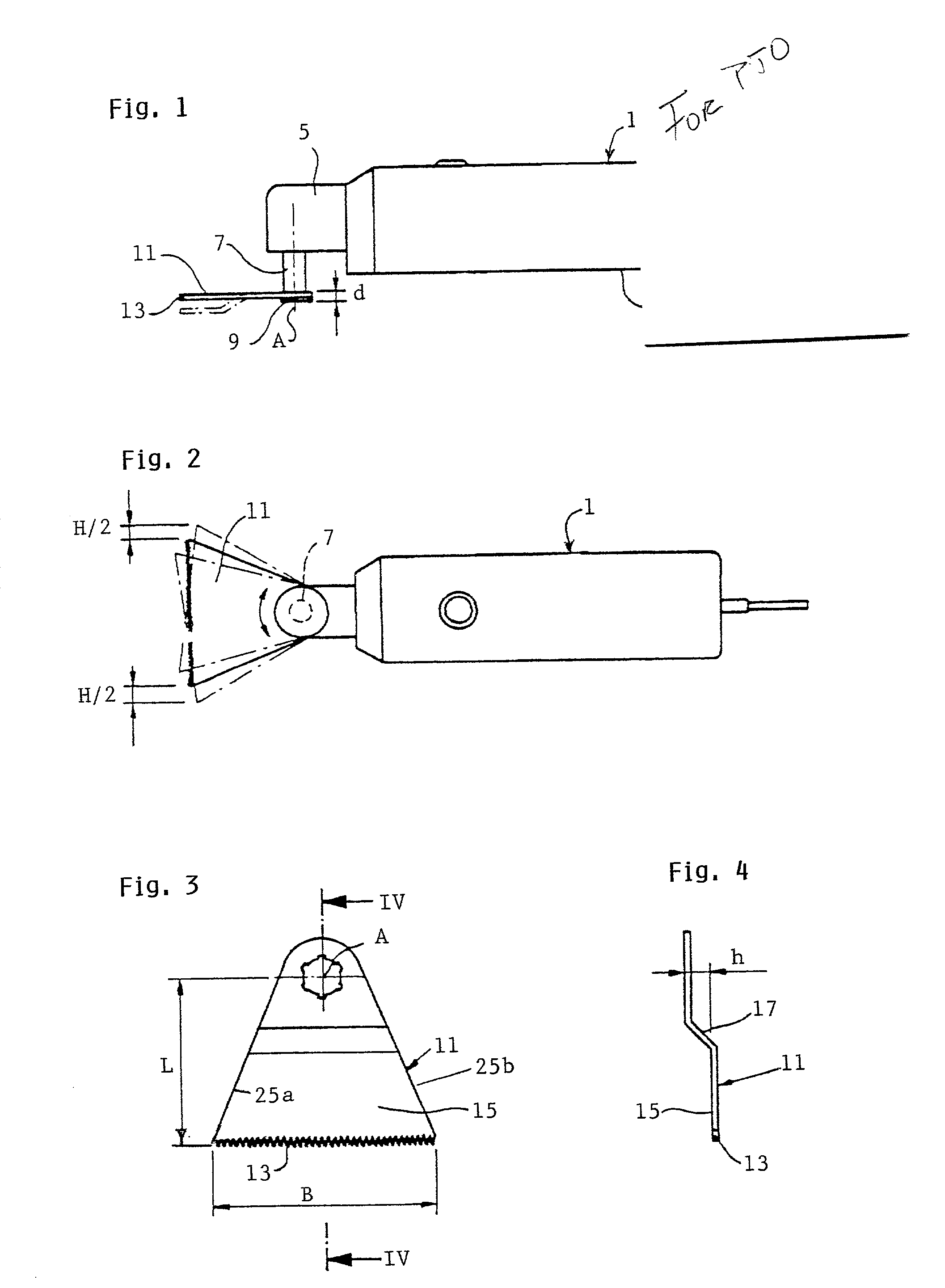

[0040] The motor-driven and manually operable implement or apparatus 1 depicted in FIG. 1 is provided with a housing including a handle 3 confining a prime mover (not shown) and a section 5 for a transmission (also not shown). The transmission is provided with an output shaft 7 extending outwardly from the housing section 5. At the free end of the shaft 7, there is provided a suitable tool fastening means, such as a chuck or a bolt 9, for rigidly attaching to the shaft a material removing tool 11. For example, the prime mover may constitute an electric or a fluid-operated (such as pneumatic) motor. The output shaft 7 is assumed to be adapted to execute oscillatory movements abut an axis A within a range of about two angular degrees and at a frequency which can be infinitely adjustable between zero and 20,000 cycles per minute.

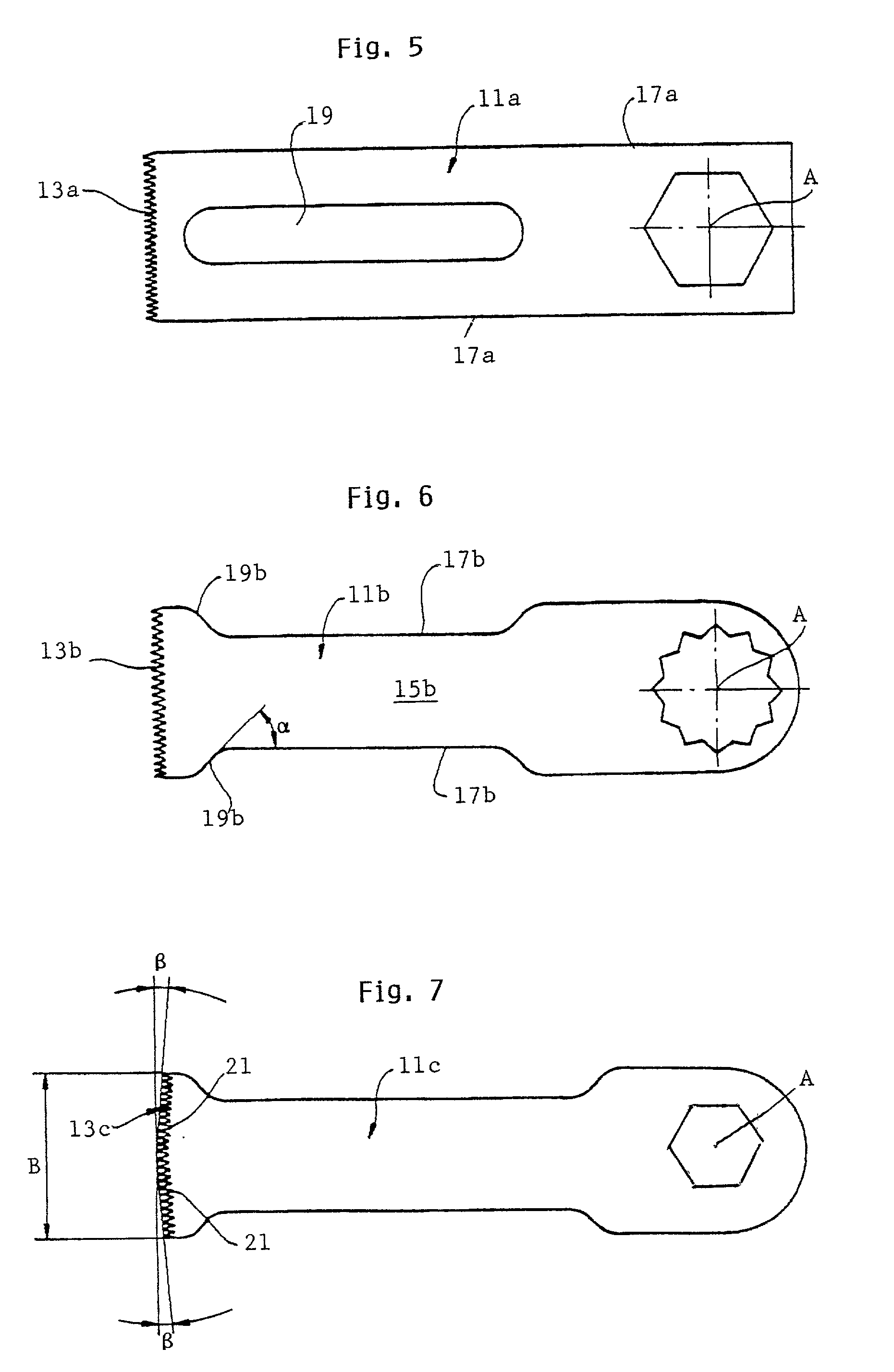

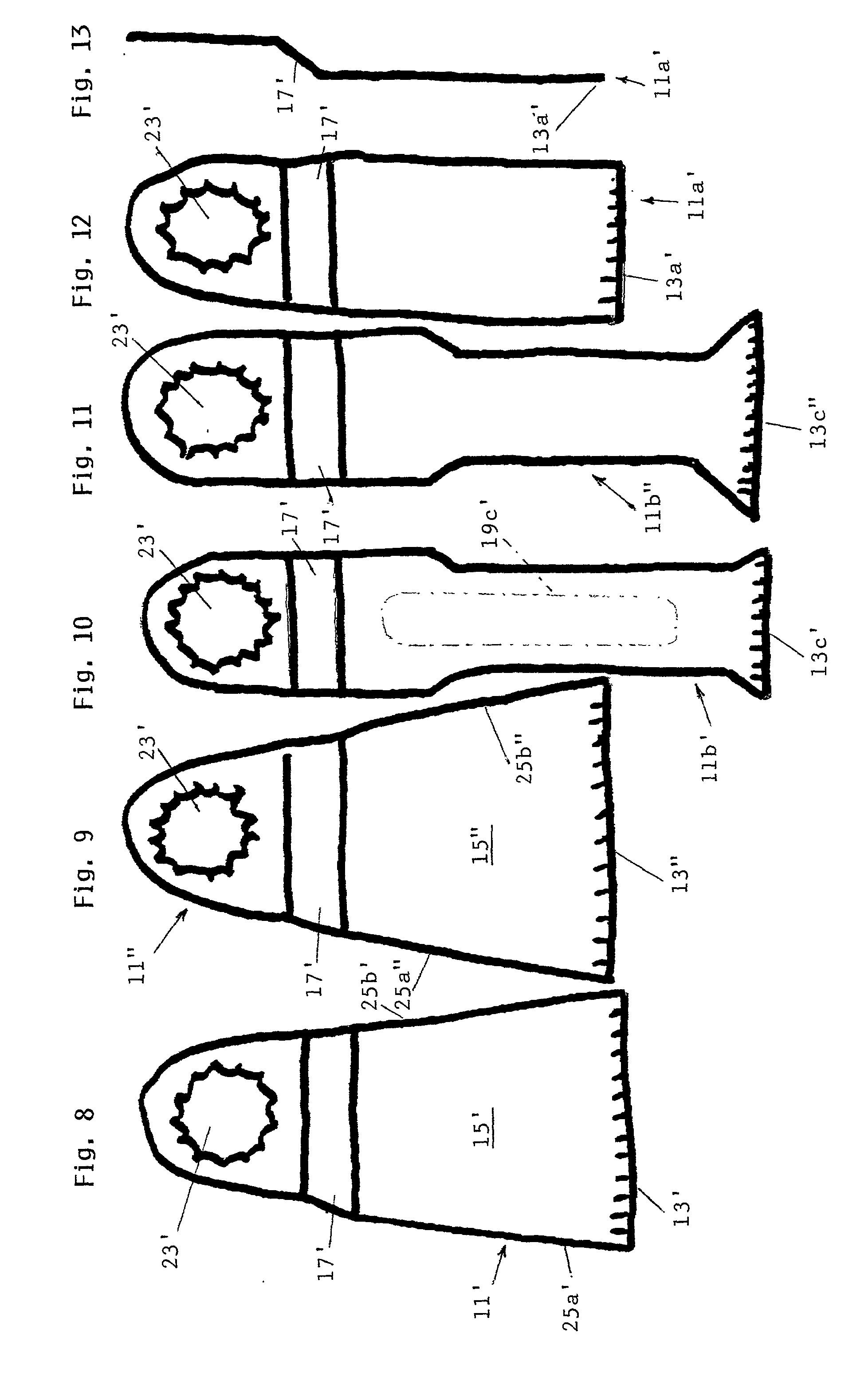

[0041] One end section of the tool 11 is provided with a cutting edge 13 defined by numerous teeth. As used herein, the term "cutting edge" is intended to embr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acute angle | aaaaa | aaaaa |

| acute angle | aaaaa | aaaaa |

| acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com