Washing composition

a technology of composition and wash, applied in the field of washing composition, can solve the problems of affecting lathering performance, relatively dense materials, and difficult to achieve and achieve the effect of effective deposition of solid active agents on the surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

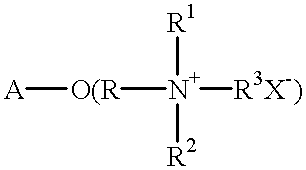

Method used

Image

Examples

example 1

Preparation of an Emulsion of Silicone Droplets Containing the Solid Antimicrobial Active Zinc Pyrithione in the Silicone Chase

[0089] 5 g of Zinc Pyrithione (Aldrich, dry powder) was mixed with 15 g of silicone oil (100 Cs, Dow Corning) to form a creamy viscous liquid. To this mixture, a further 30 g of high viscosity silicone oil (60,000 Cs, Dow Corning) was added and the mixture stirred thoroughly.

[0090] 150 g of SLES-2EO (26 %) was stirred, and 11 g of the Zinc Pyrithione / silicone oil mixture prepared as described above was added. The mixture was stirred until a homogeneous dispersion was formed. To this was added 11 g of a 10% Carbopol gel and the mixture again stirred until homogeneous.

[0091] Observation under optical microscopy showed that the product comprised an emulsion of silicone oil droplets, with Zinc Pyrithione predominantly encased within the silicone oil droplets.

example 2

Preparation of a Shampoo Composition

[0092] The emulsion of Example 1 was formulated into a shampoo composition by mixing with a solution of SLES-2EO, JAGUAR C13S and formalin to give a shampoo having the composition shown in the Table below, in which all amounts are expressed in % by weight of the total shampoo composition.

1 TABLE Ingredient % by weight Zinc Pyrithione 0.55 silicone oil (100 Cs) 1.65 silicone oil (60,000 Cs) 3.30 SLES-2EO 16.00 JAGUAR C13S 0.30 Carbopol 0.55 Formalin 0.10 Water to 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com