Cargo lash to bar

a technology of lashing and cargo, applied in the field of new mechanisms, a bar, can solve the problems of multiple chains being stretched, equipment dangerously coming loose, d-rings, lashing gear,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

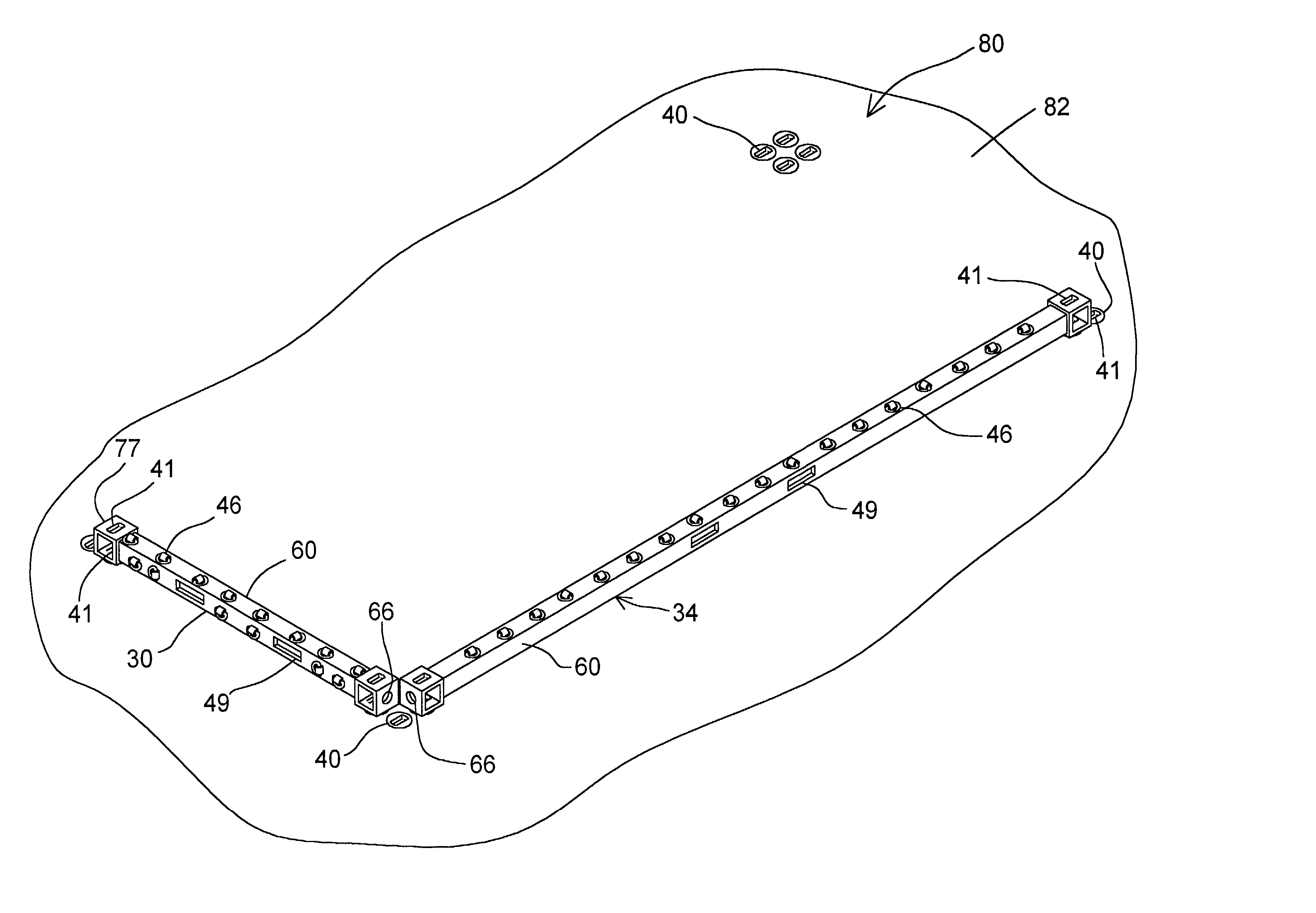

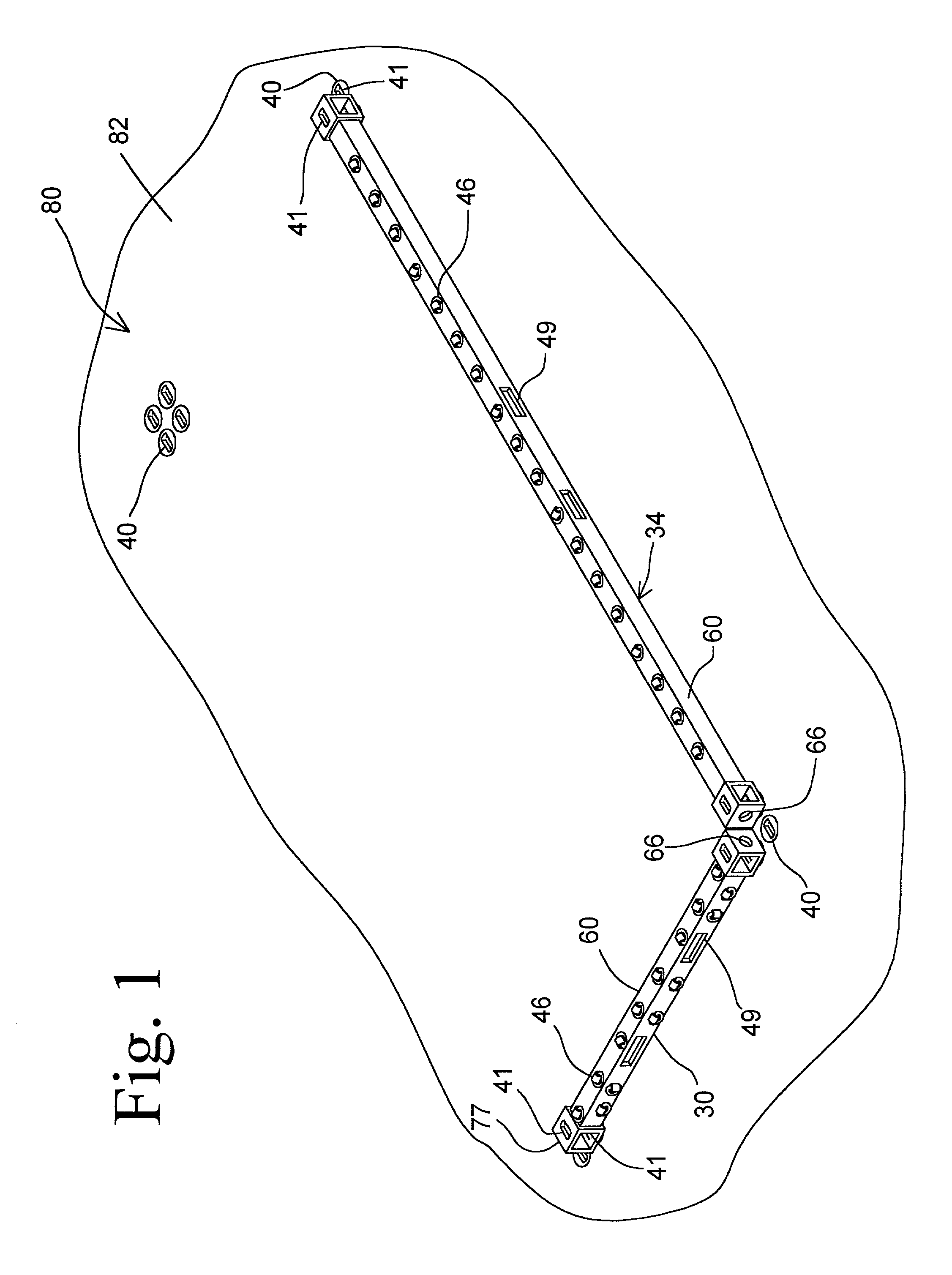

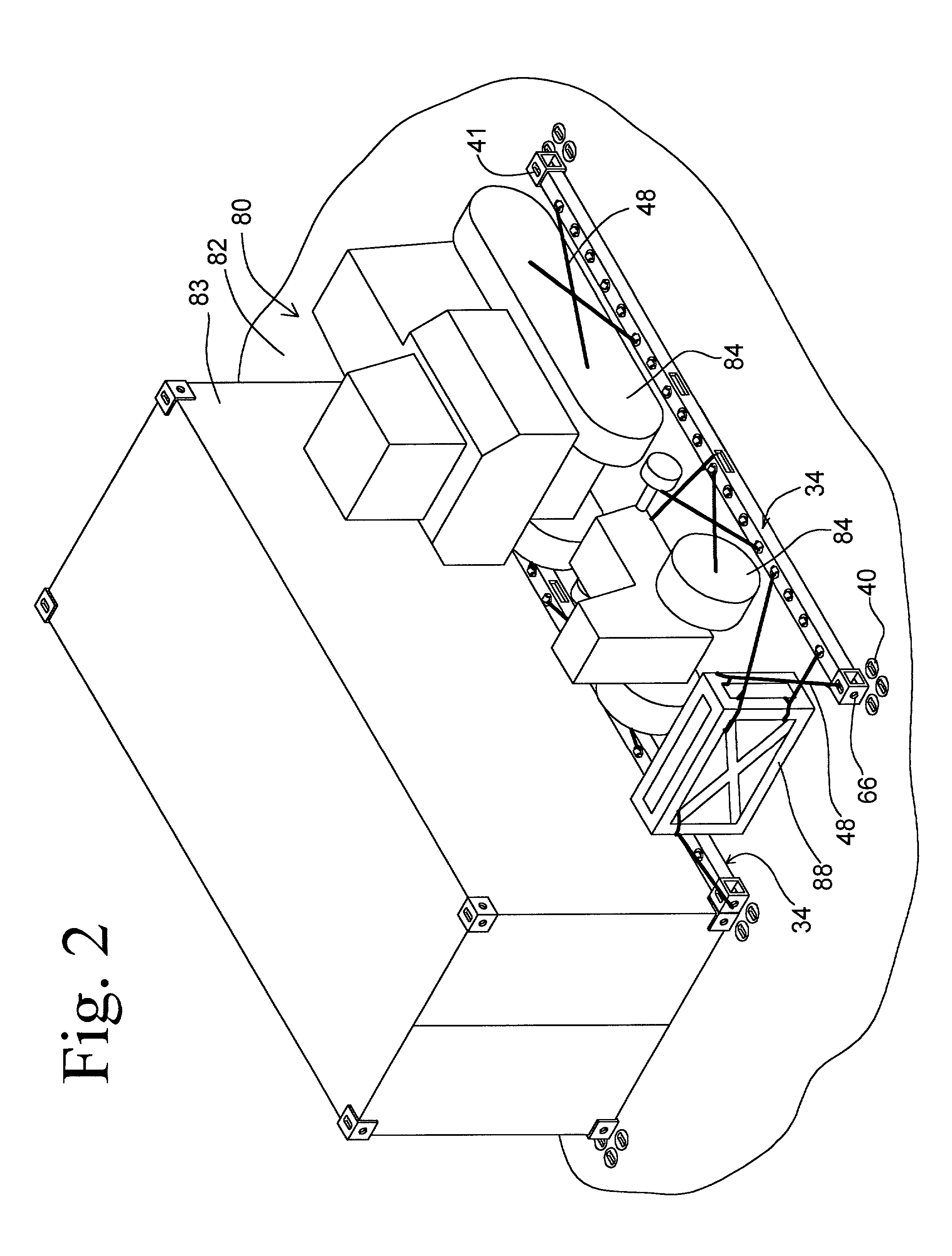

[0037] Referring to the drawings, the preferred embodiment of the present invention, cargo lash to bar assembly 30 and also lash to bar assembly 34 shown in FIG. 1, is a beam which is a structural steel tubing member 60 that spans from one twist lock 50 to another twist lock 50, for mounting athwartship or fore to aft on a ship's deck 82, having locking bolt mounting apertures 41 in the bottom surface of structural member 60 toward each end to receive the insertion of twist locks 50 in member 60, that match the spacing of a commercially available freight container 83, to facilitate removable connection of lash to bar 30 and 34 to a pair of ISO type twist lock mounting sockets 40 attached a ship's deck 82. The cargo lash to bar 30 and 34 has several D-rings 46 attached to member 60 along the length through which a strap, cable, or chain herein called a lashing 48 may pass for lashing or restraining cargo to. A D-rings 46 consist of any lashing ring 68 and a lashing ring restraining m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com