High-precision computer-aided microscope system

a computer-aided microscope and high-precision technology, applied in the field of microscopy, can solve the problems of inaccurate or imprecise microscope configurations, inability to diagnose sample specimens, and inability to accurately identify sample specimens, etc., and achieve the effect of reducing the number of manual and automatic microscope systems, and improving the accuracy of manual and automatic configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

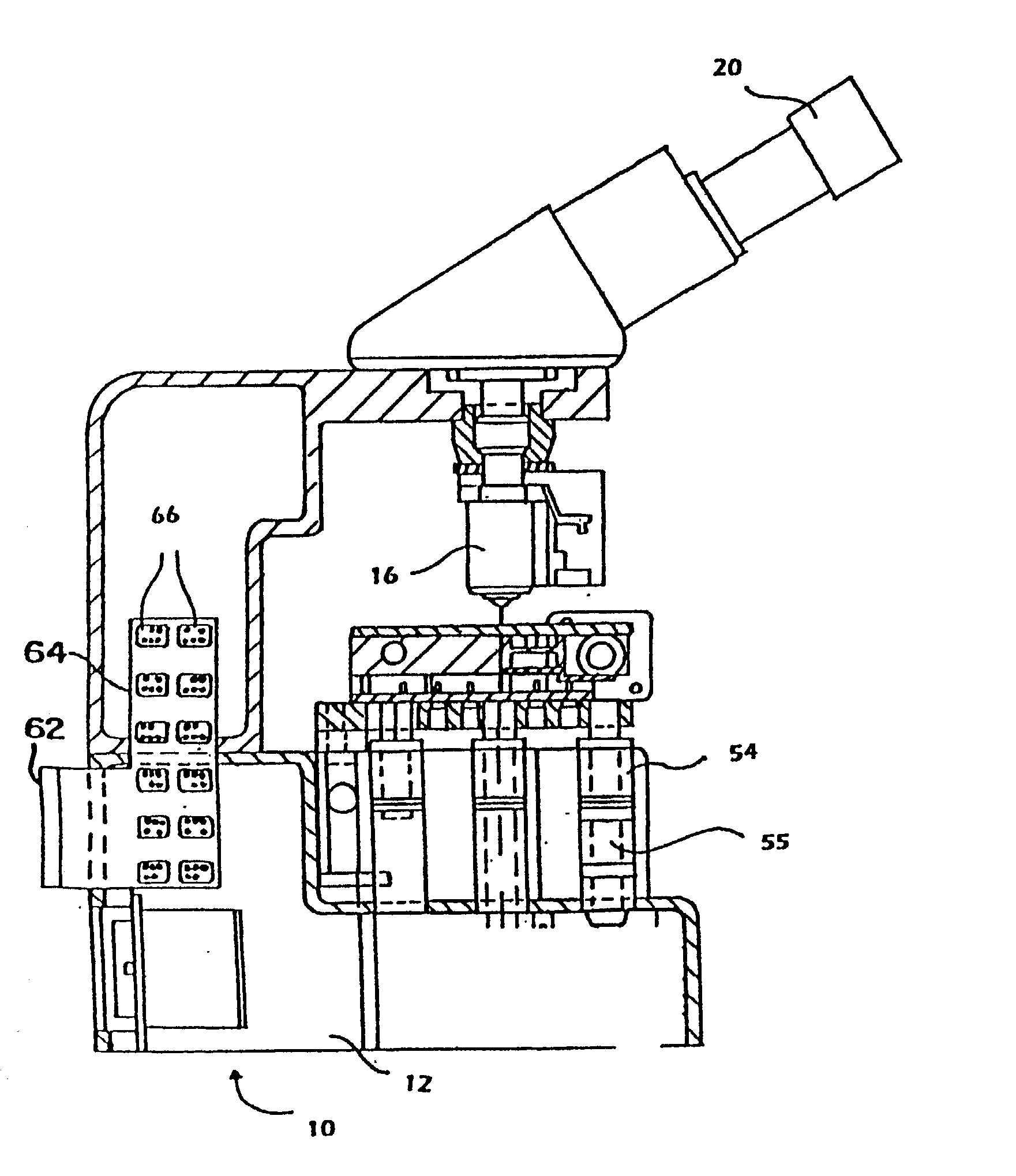

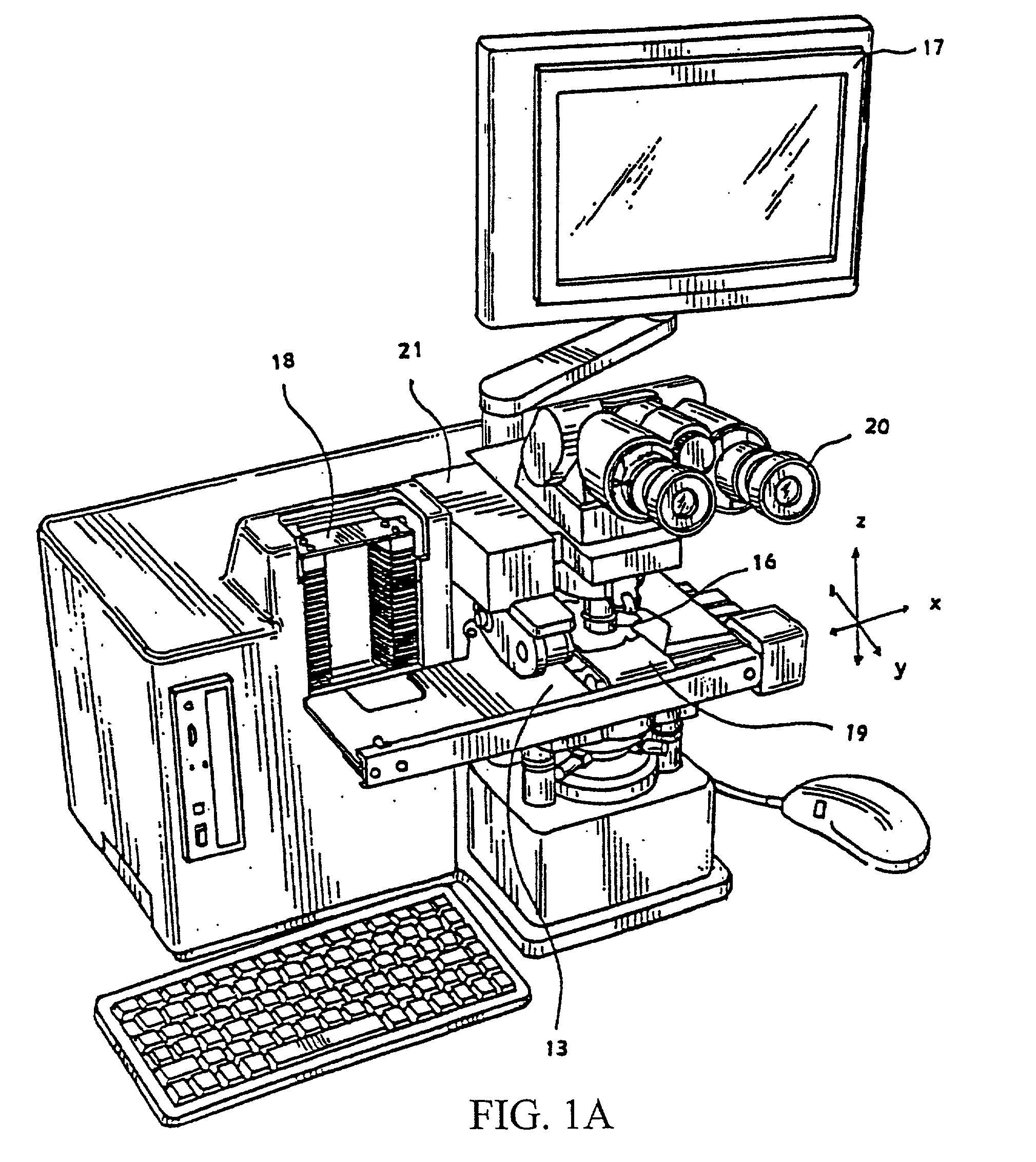

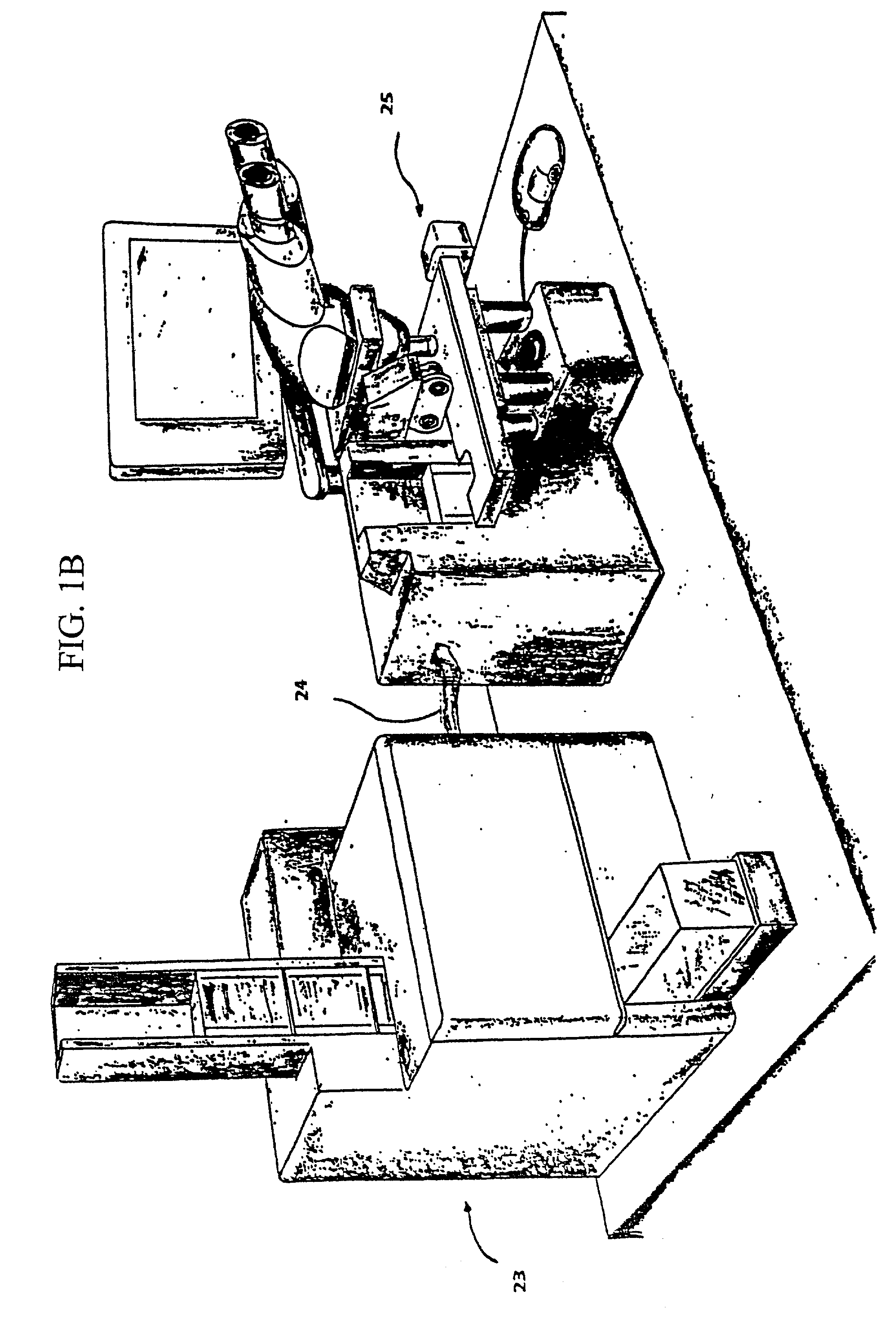

[0055] Referring to FIGS. 1-6, there is shown a schematic block diagram of a system that incorporates the principles of the invention. In particular, the Figures illustrate a system having the capability to capture images of a sample from a specimen collected from an individual and placed upon a slide, and to analyze the sample rapidly, accurately, and precisely. The microscope system may be incorporated into a variety of settings and a variety of applications.

[0056] Exemplary Applications for Microscope System

[0057] Referring to FIG. 1A, there is shown one example of a suitable configuration employing a microscope system according to the present invention. An automated video microscope having image analysis capabilities is coupled to a Data Management System (DMS). In one embodiment of the invention, the DMS comprises a conventional computer system with a processor and memory that contains patient medical history and demographic data relevant to the specimens being screened. The DM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com