Atomizer for applying liquids onto eyes

a liquid application and atomizer technology, applied in the field of atomizers for applying liquids onto eyes, can solve the problems of not all patients finding it easy to administer drops of liquid into their own eyes, children and elderly people in particular, and patients will accidentally stick the applicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

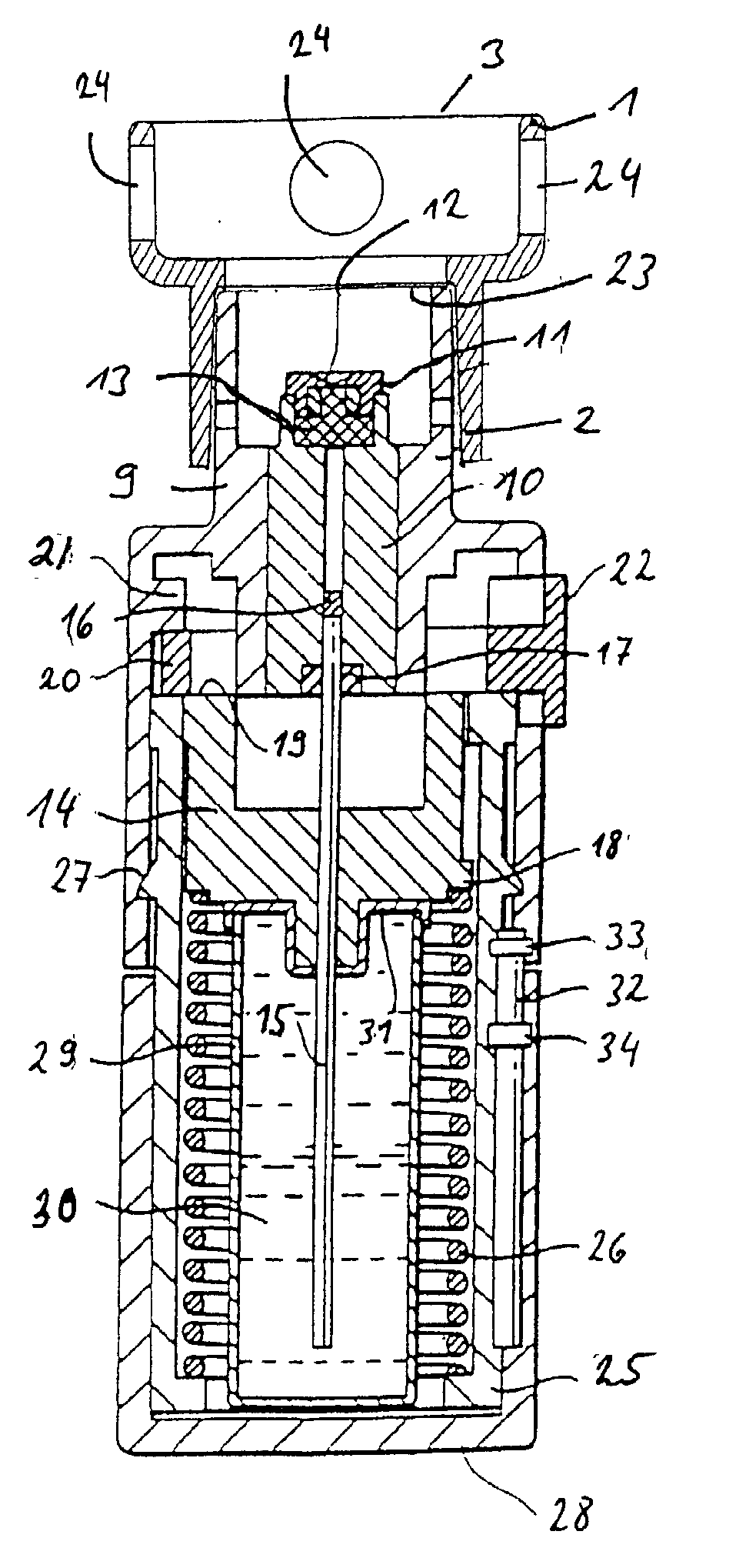

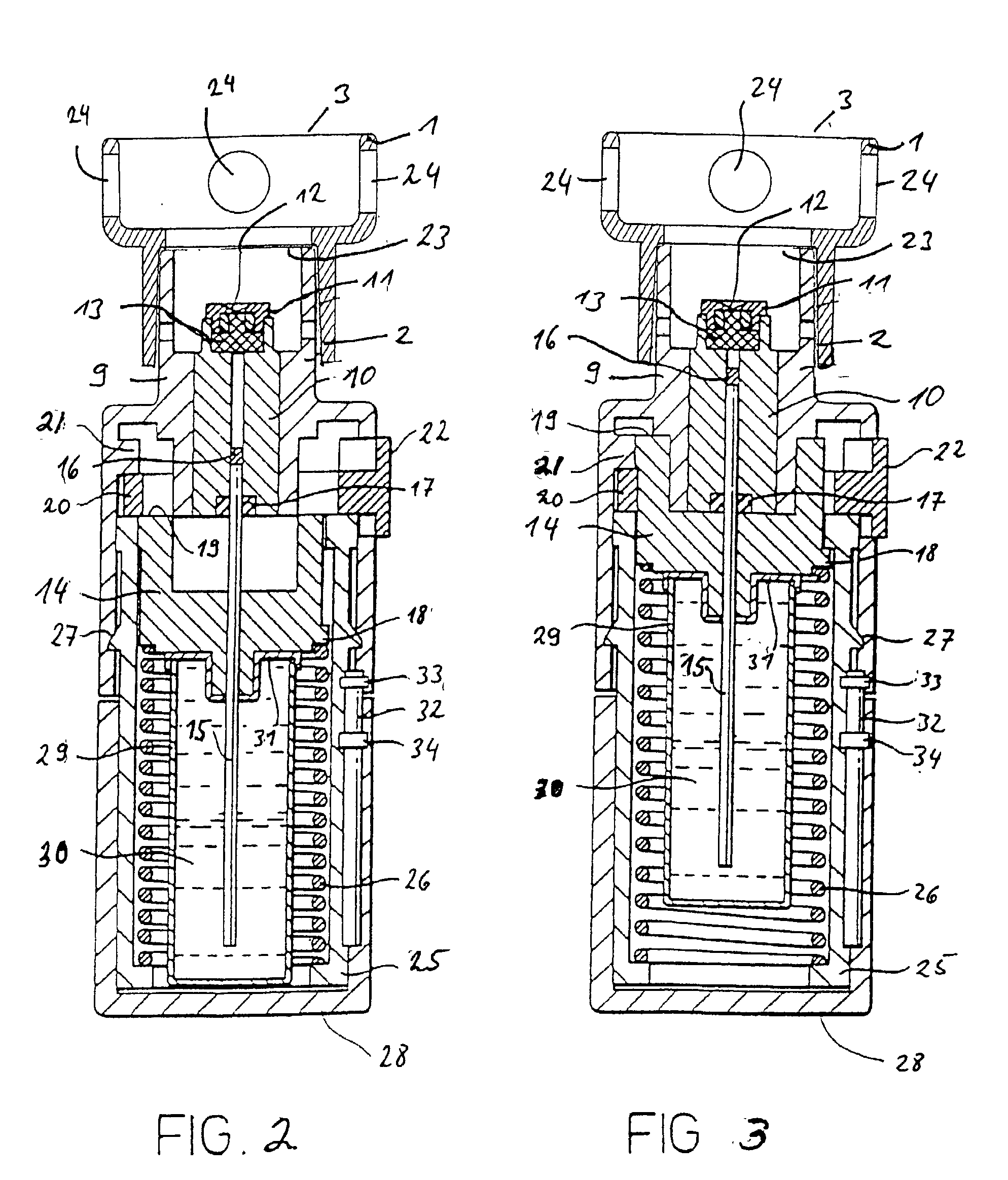

[0103] The volume of a spray jet delivered with the atomizer described above, known by the trade mark Respimat.RTM. is e.g. 12 microlitres and the mass is therefore 0.000012 kg. At a distance of 2 cm from the nozzle the speed of the cloud of droplets as a whole is 3.3 m / s and the pulse is roughly 0.0004 kg*m / s. With a spray duration of 1.2 s a force K of 0.033 milliNewtons is thus obtained, corresponding to a weight of about 3.3 mg.

[0104] By comparison, an atomizer which delivers a mass of 0.0001 kg of 0.1 ml and has an average spray duration of 0.12 seconds would generate a cloud of particles with a force of 7.5 milliNewtons, corresponding to a weight of about 750 mg. This presupposes that the nozzle diameter is 0.344 mm and the droplets produced are 100 microns in size. This results in a speed of the cloud of particles of about 9 m / s. The large droplets are hardly slowed down at all before making contact with the eye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com