Biodegradable cotton composites

a technology of biodegradable cotton and composites, applied in the field of composite materials, can solve the problems of more difficult thermal bonding between poly(lactide) fibers and fabrics, and other parts are either partially or non-biodegradabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

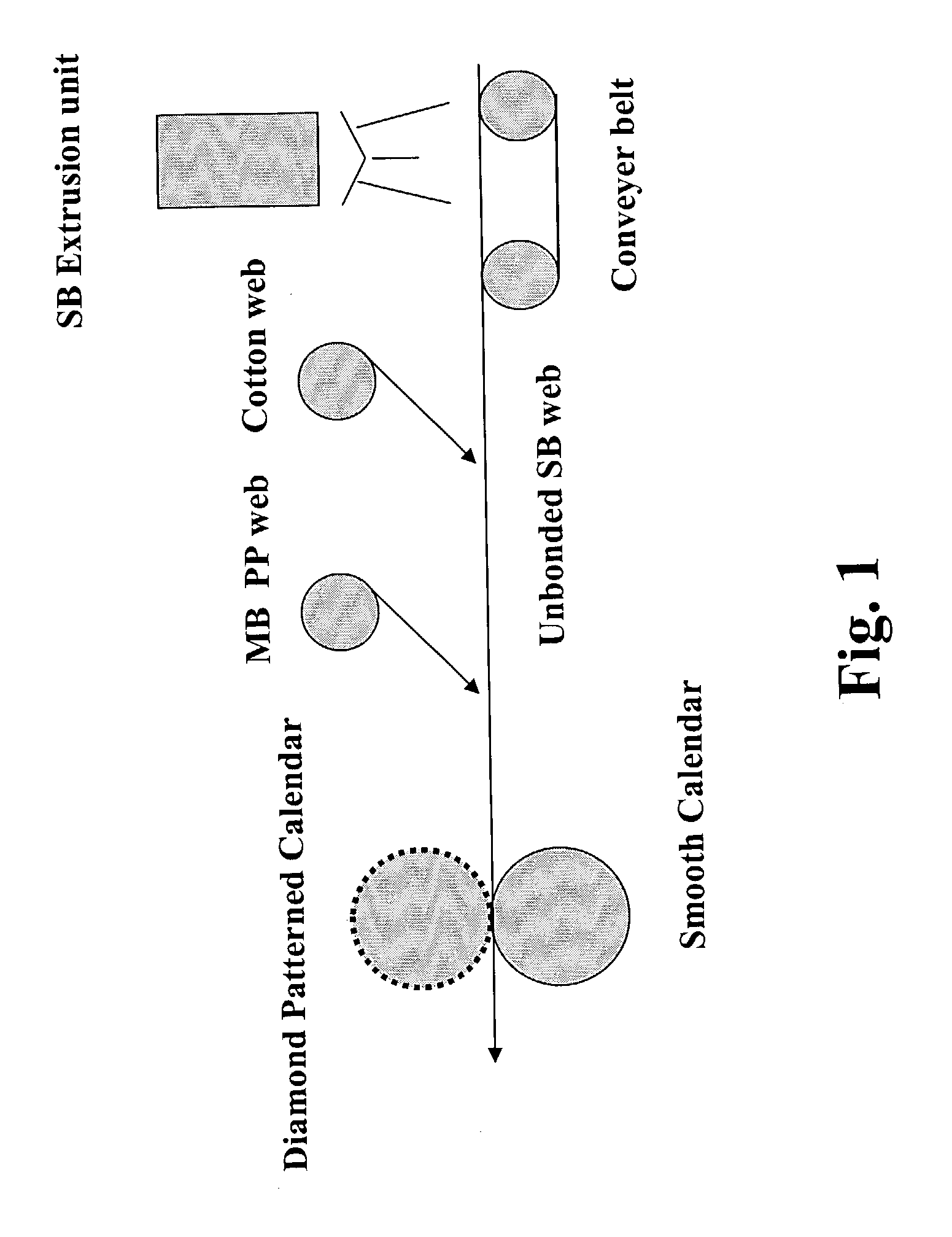

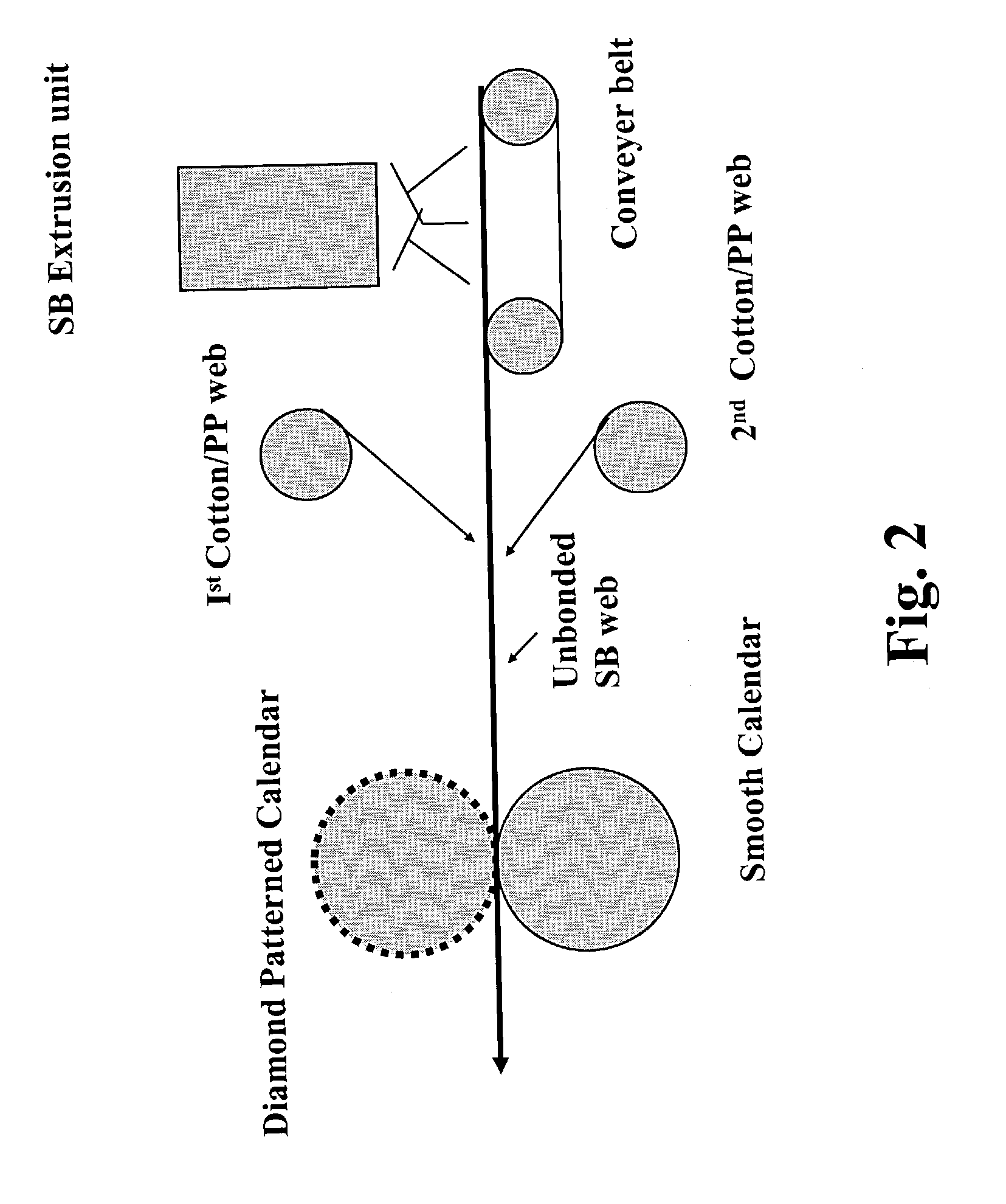

Method used

Image

Examples

Embodiment Construction

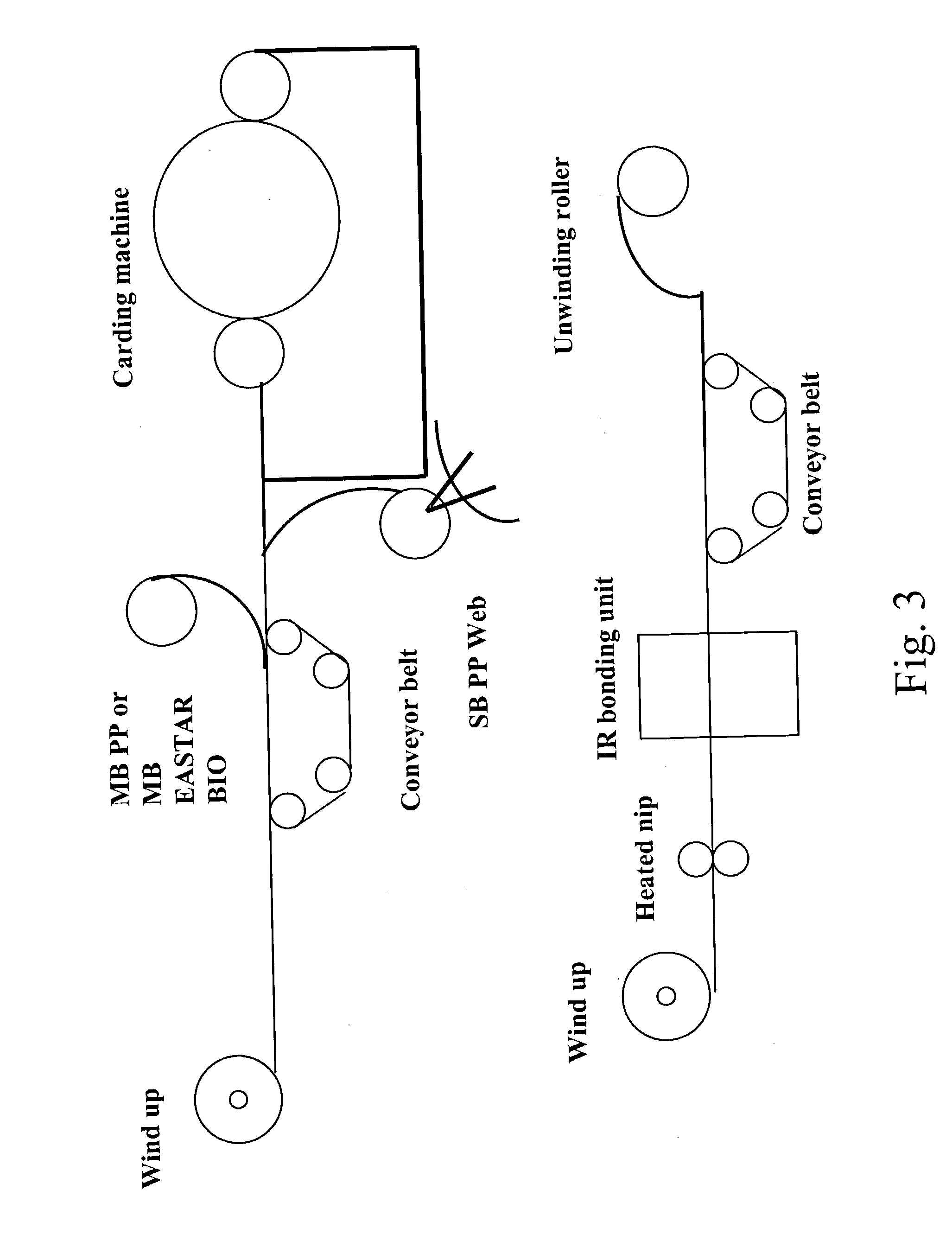

[0026] EASTAR BIO GP COPOLYESTER ("EASTAR BIO") is marketed by the Eastman Chemical Company of Kingsport, Tenn.. Spunbond / Cotton / meltblown (SCM) Cotton-Core Non-wovens (CCNs) comprising a biodegradable web, such as one comprising a totally biodegradable polymer such as an EASTAR BIO meltblown web instead of meltblown polypropylene webs, were produced and compared to CCNs containing polypropylene in both the meltblown and spunbond components. The absorbent cores had a weight of 1.5 oz / yd.sup.2 (51 g / m.sup.2) and consisted of carded 75 / 25 and 50 / 50 Cotton / polypropylene staple fiber blends. The laminates were all infrared bonded and evaluated for tearing strength, tenacity, and water absorption rate and maximum absorption. Use of EASTAR BIO meltblown in place of meltblown polypropylene resulted in stronger well-bonded laminates with exceptionally high absorbency on the EASTAR BIO meltblown side as well as in the cotton core.

[0027] Cotton-based non-woven materials may include cotton-cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com