Damper mechanism

a technology of adamant mechanism and a rotor, which is applied in the direction of mechanical actuated clutches, friction linings, couplings, etc., can solve the problems of excessive torque generated at the tires, excessive shaking of the vehicle, and transmission to rattl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

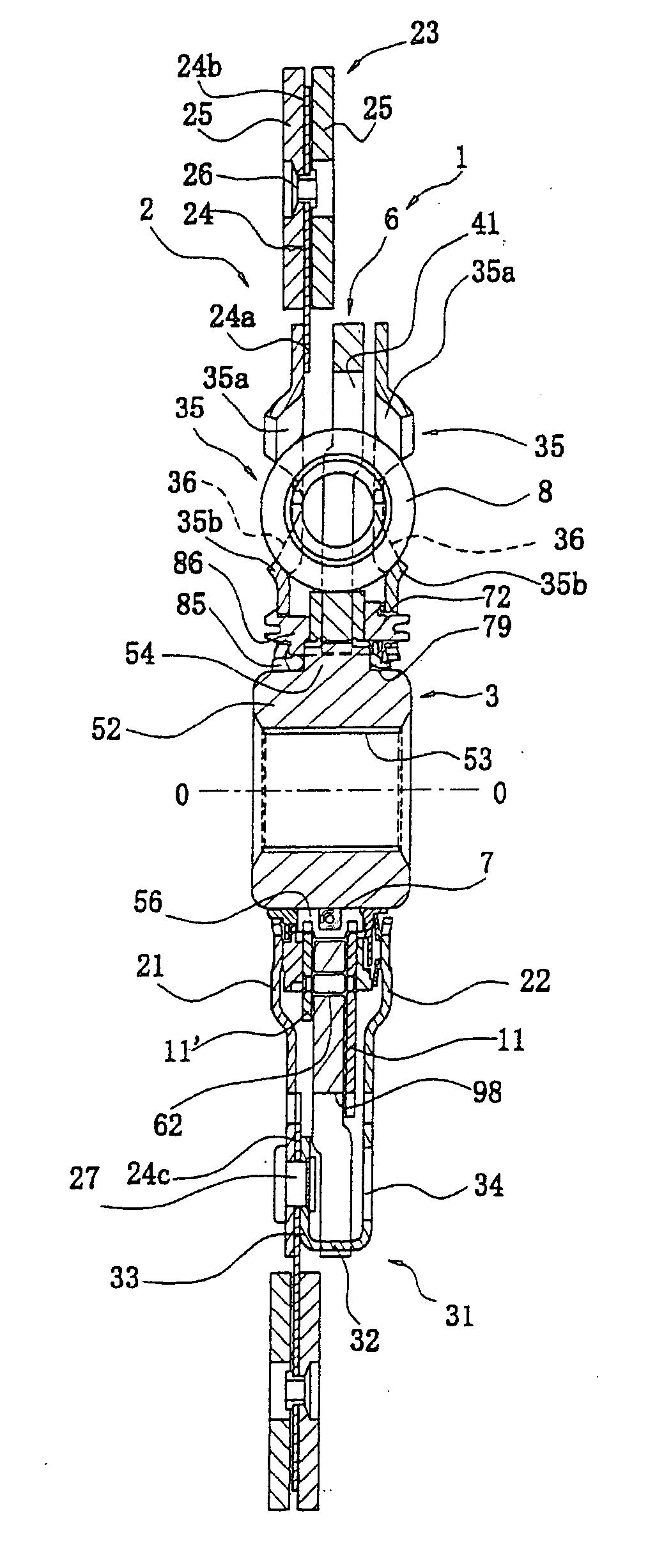

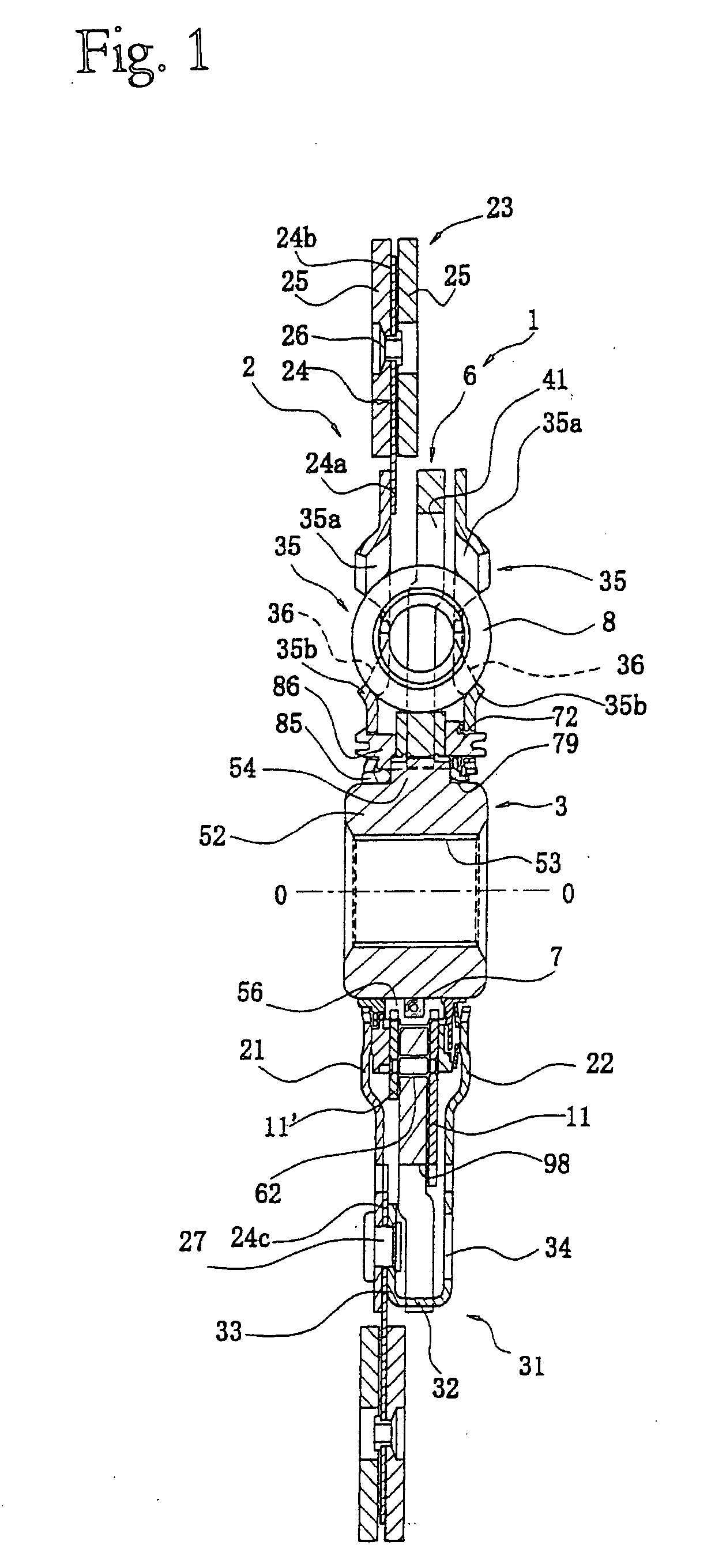

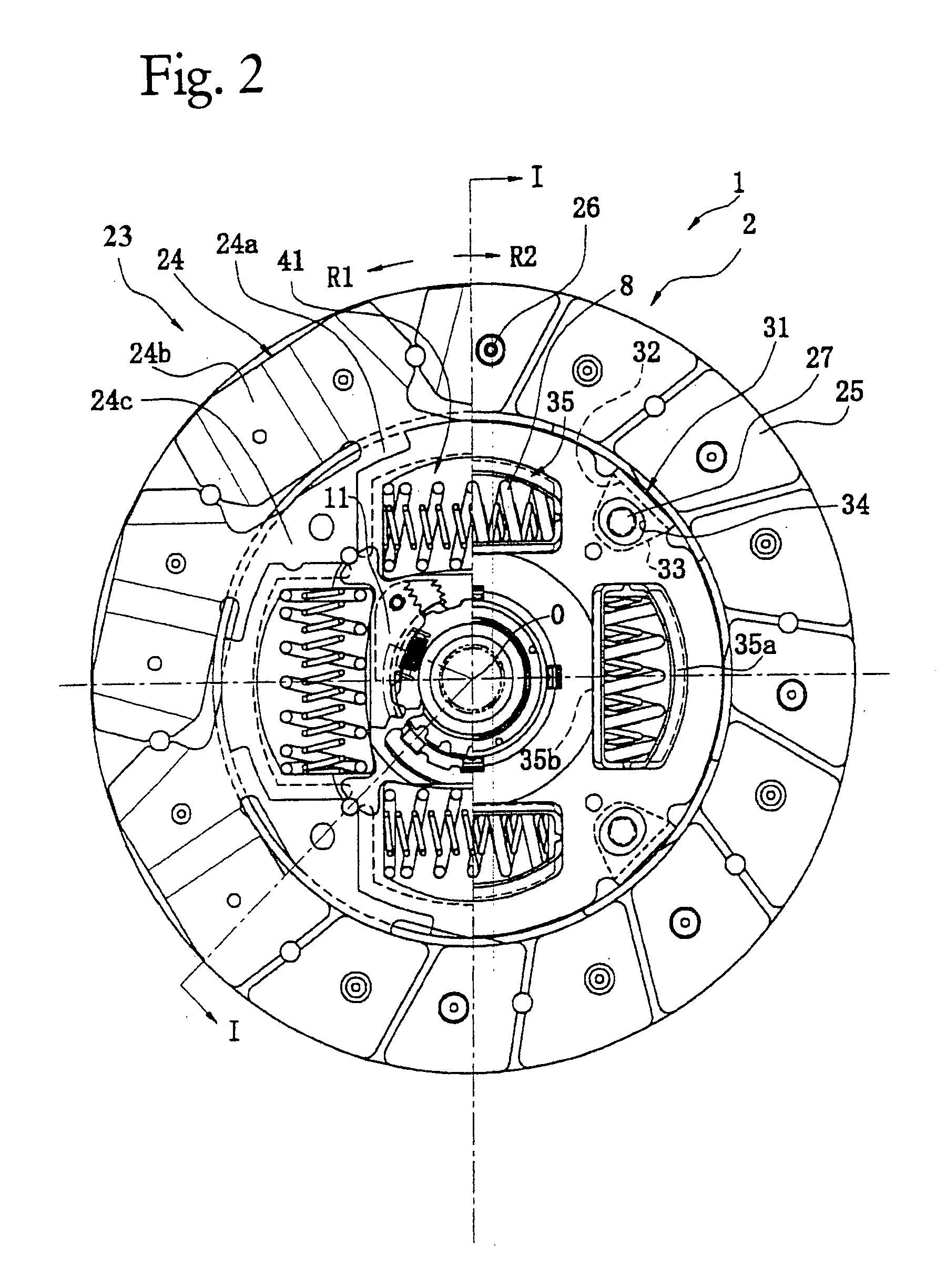

[0082] A damper mechanism in accordance with alternate embodiments of the present invention will now be discussed. In view of the similarities between the alternate embodiments and aforementioned embodiment, discussed above, the components or parts of the alternate embodiments that have the same function of the corresponding components or parts of the aforementioned embodiment are being given the identical reference numerals. Moreover, the explanations of components or parts and the operations of the alternate embodiments that are similar to components or parts and the operations of the first embodiment will be omitted. Only components and operations of the alternate embodiments that are different in structure and function from the aforementioned embodiment will be explained herein.

[0083] As shown in FIGS. 20 and 21, it is also acceptable to provide the elastic members 104 on both rotational direction sides of the stud pins 62. Here, each hole 69 has the first hole 101 and a pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com