Method for strengthening or repairing an existing reinforced concrete structural element

a technology of reinforced concrete and structural elements, applied in structural elements, building repairs, building components, etc., can solve the problems of difficult bending of steel reinforcements to form spiral steel reinforcements, and the method is not suitable for strengthening or repairing existing structural elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

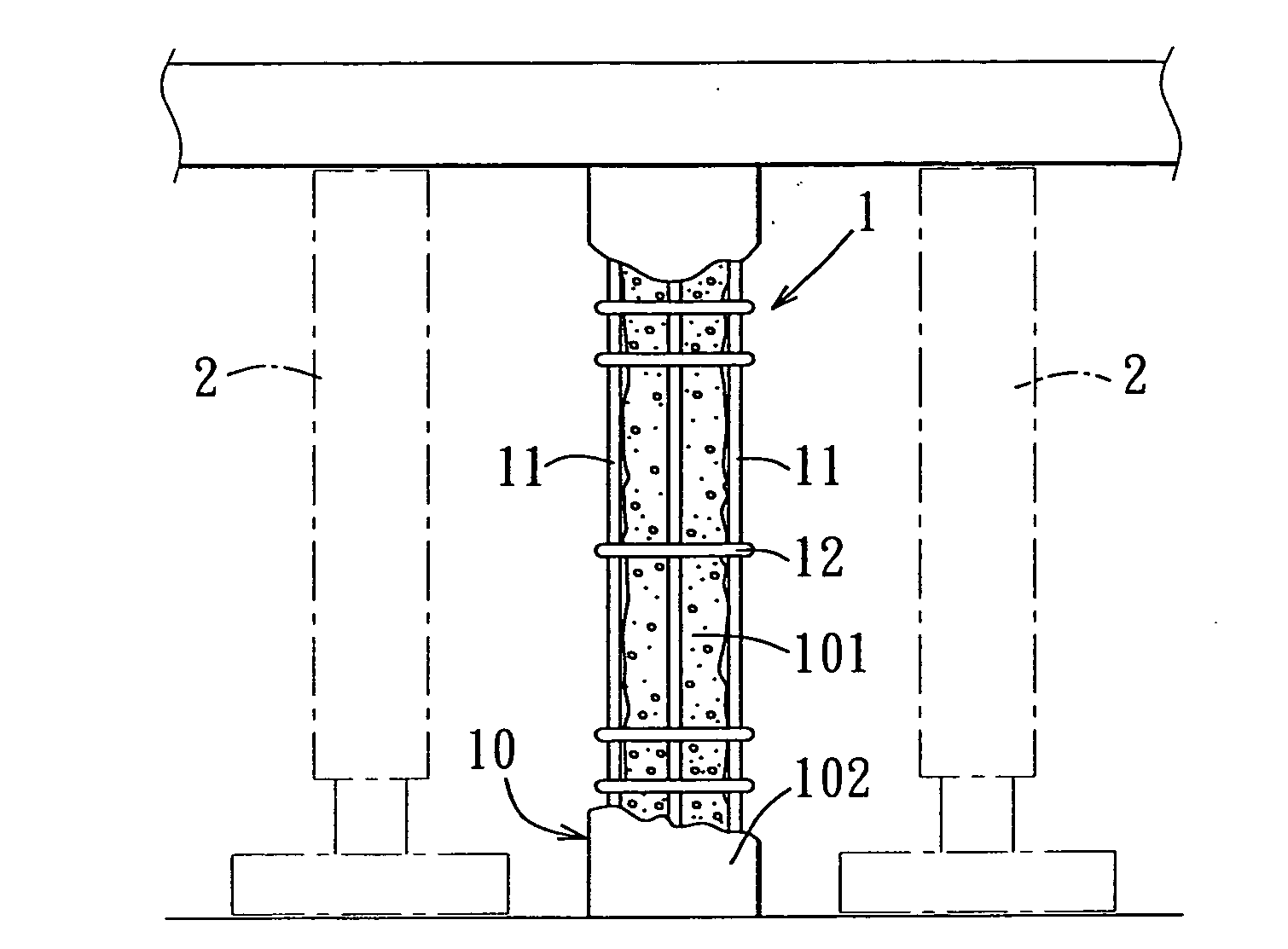

[0025] A standard test sample of a rectangular reinforced concrete column was prepared. The reinforced concrete column has a 50 cm.times.50 cm cross-section and a height of 170 cm, and includes twelve #8 longitudinal steel reinforcements, each of which has a yield strength of 412.0 MPa, and a number of #3 lateral steel reinforcements (which serve as ties), each of which has a yield strength of 274.4 MPa. The spacing is about 40 cm for two adjacent lateral steel reinforcements. The concrete of the reinforced concrete column has a strength of about 20.5 MPa. The reinforced concrete column has a foundation with a size of 245 cm.times.180 cm.times.74 cm (length.times.width.times.height) The foundation includes eleven #8 steel reinforcements which are evenly distributed along a periphery of the foundation.

[0026] During the cyclic loading test, a hydraulic axial force (52.5 tons) was applied to the top end of the reinforced concrete column, and a lateral force was applied to one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com