Cooling plate and manufacturing method thereof, and sputtering target and manufacturing method thereof thereof

a technology of cooling plate and manufacturing method, which is applied in the direction of manufacturing tools, lighting and heating apparatus, instruments, etc., can solve the problems of further productivity and cost, unsatisfactory quality and accuracy, and inability to achieve direct cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

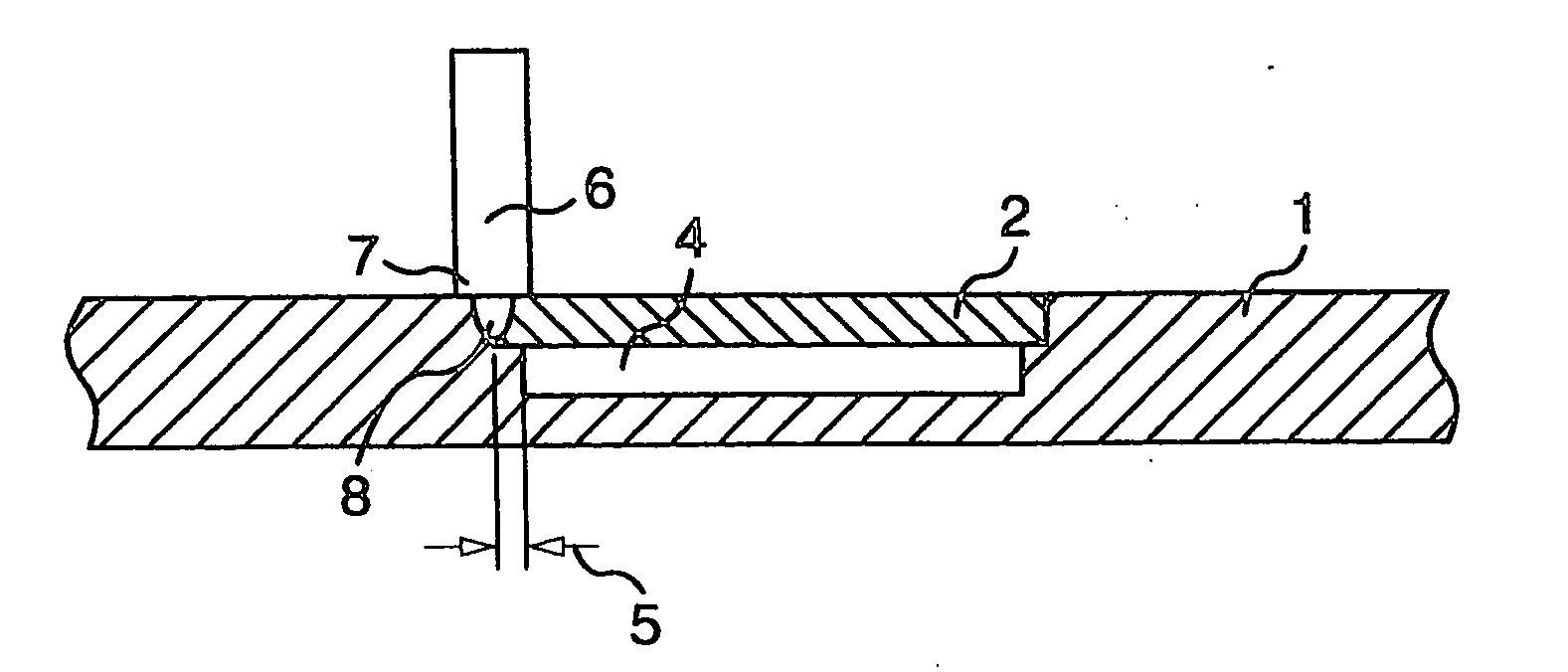

[0056] FIG. 1 is a schematic front view of a backing plate as a cooling plate made of oxygen free copper or a copper alloy containing 5% or less of Zr or Cr. The backing plate consists of a body 1 and a lid 2. A U-channel 4 is provided in the body 1, the lid 2 covers the channel 4, and, the lid 2 and channel 4 have the same plane and zigzag geometry although the lid 2 and channel 4 differ from each other in dimensions of U-shapes. Otherwise, I-shaped and S-shaped channels or the like are preferable. In addition, an R section 3 is provided in each corner section of the lid 2 in order to make the lid 2 easily inserted in the body 1. The lid 2 has the structure of being received with a step of the body 1, and can receive the force of the rotation tool 6 on the occasion of the friction stir welding.

[0057] The dimensions of the body 1 are 1500 L.times.1200 W.times.15 D mm. In he case of this FIG. 1, there are five channels 4 for cooling. If he dimensions are 1300 L.times.900 W.times.15 D...

embodiment 2

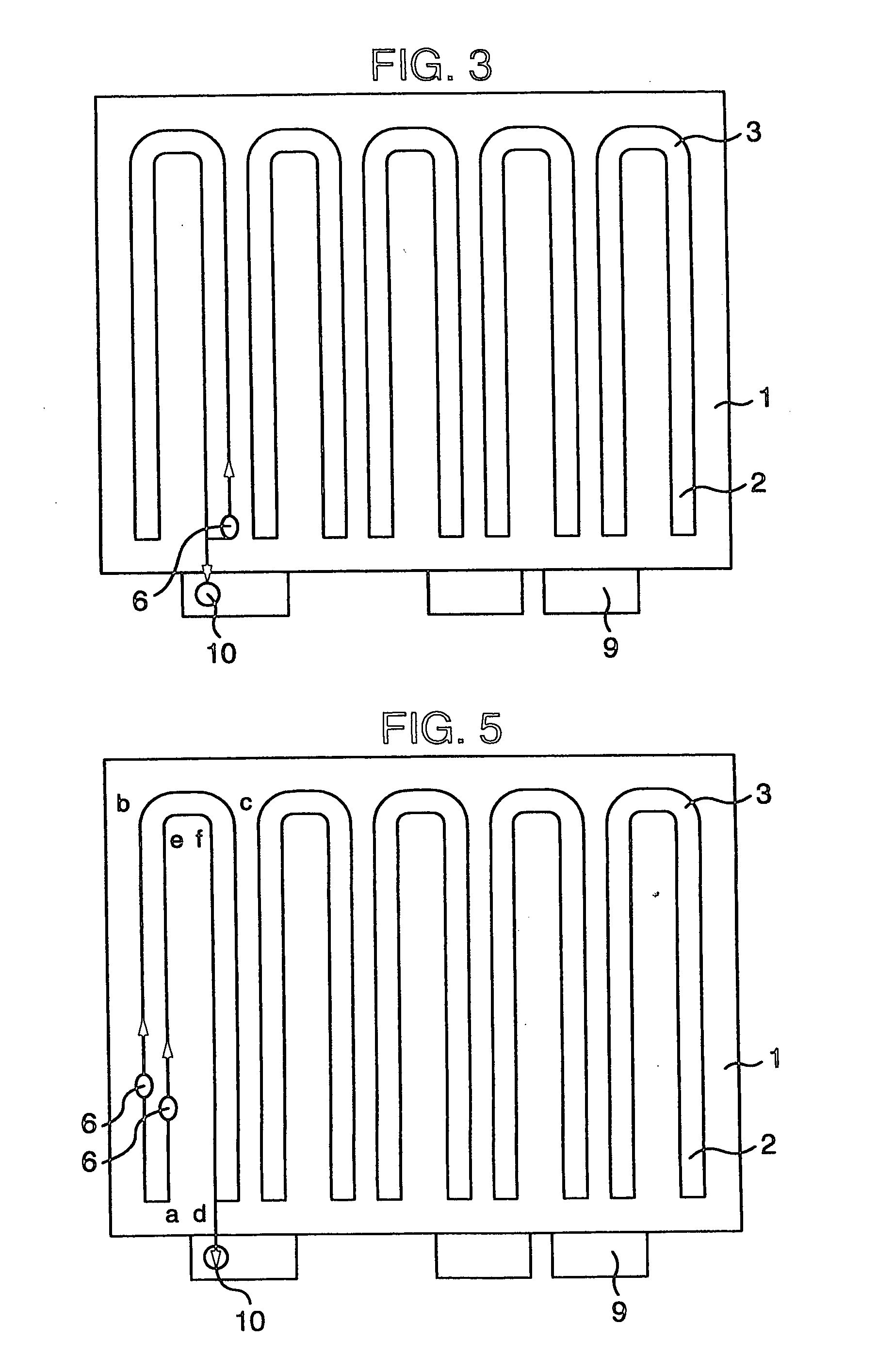

[0065] This embodiment relates to the joining of the backing plate similar to that in FIG. 1, and in particular, a joining example about the R section 3 will be described. The rotation speed of a rotation tool, joining speed, and rotation tool geometry are the same as those in the first embodiment. As shown in FIG. 5, after first inserting the rotation tool 6 in a position "a", joining was performed in the path of a.fwdarw.b.fwdarw.c.fwdarw.d under the above-described conditions, and the end section 10 was made to be the dummy 9. Next, after inserting the rotation tool 6 in a position "a" again, joining was performed in the path of a.fwdarw.e.fwdarw.f.fwdarw.d, and the end section 10 was similarly treated. What is important at this time is that the rotation tool 6 always turns to the right in the R section 3. When the rotary direction of the rotation tool is clockwise contrary to this, what is necessary is just to perform joining so that the rotation tool may always turn to the left...

embodiment 3

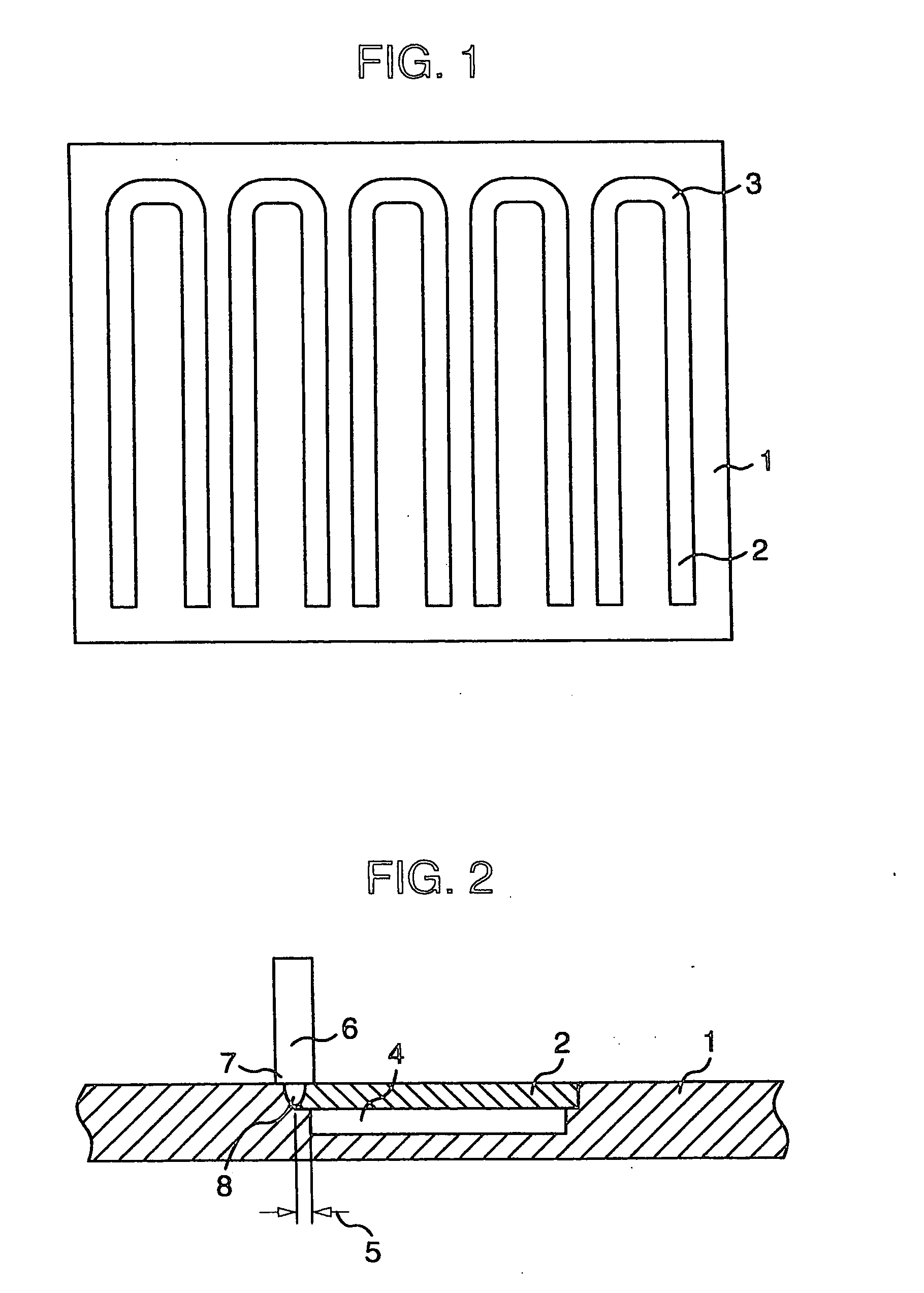

[0067] What are examined in this embodiment are the overlapping width 5 shown in FIG. 2, and the distance (offset) apart from a joining beveling of the centerline of the rotation tool 6 in a direction opposite to the channel 4. The geometry of the rotation tool that is used is the same as that in the first and second embodiments. In addition, joining conditions are the same.

2TABLE 2 Overlapping Maximum radius width Offset of pin State of w (mm) x (mm) W + x (mm) r (mm) joining 2.5 0 2.5 4.0 Collapse 2.5 1 3.5 4.0 Collapse 2.5 1.5 4.0 4.0 Good 1 0 1.0 4.0 Collapse 2 0 2.0 4.0 Collapse 3 0 3.0 4.0 Collapse 4 0 4.0 4.0 Good

[0068] As shown in Table 2, in order to obtain normal joining, it is preferable that w+x.gtoreq.r. That is, it is required for that the weld bead that is formed is in the outside of the channel. Moreover, a reason why the sample was not successful in joining is that the lid was collapsed due to the load received from the rotation tool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| resistance force | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com