Keyed latch valve for fuel filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

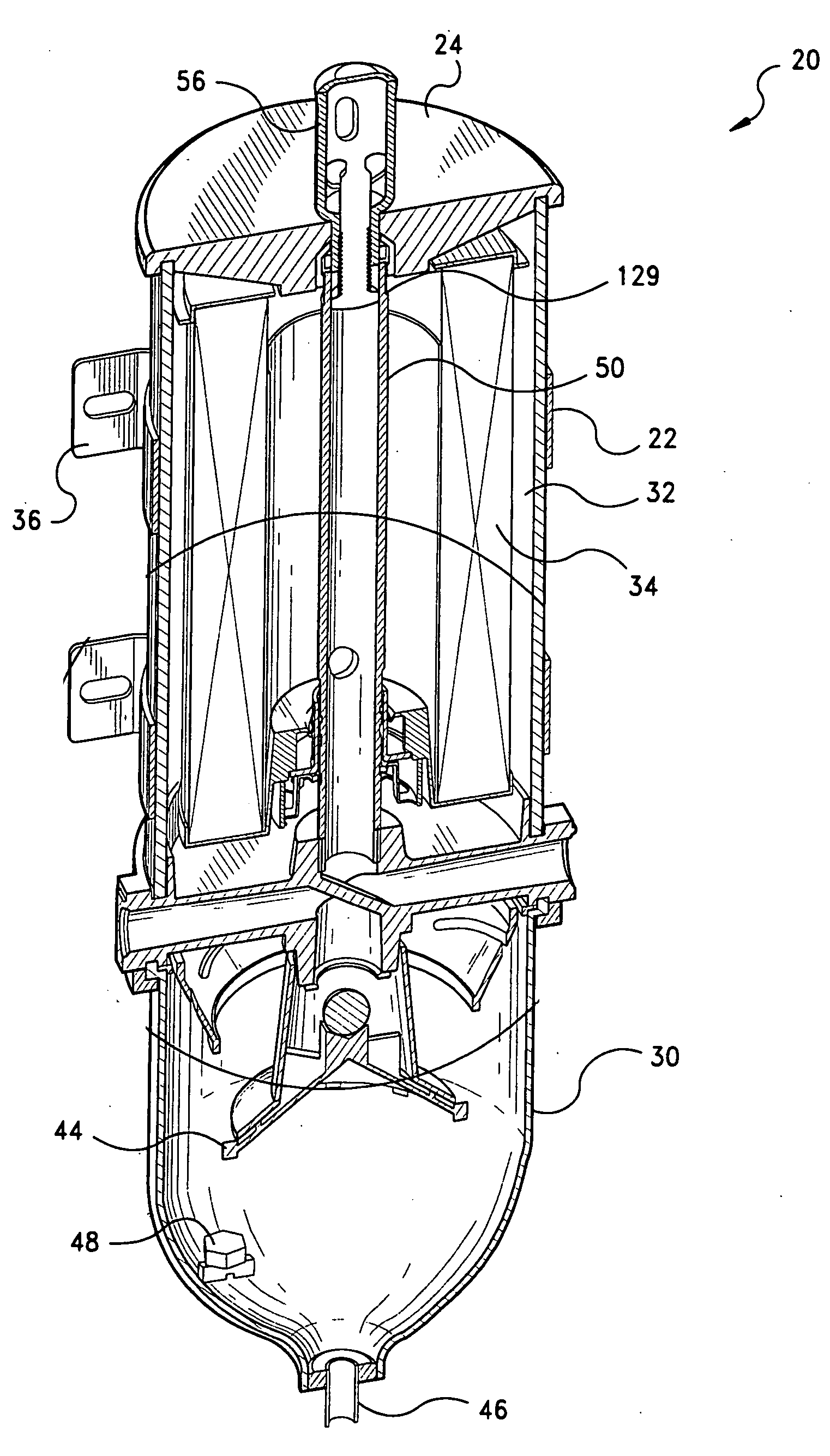

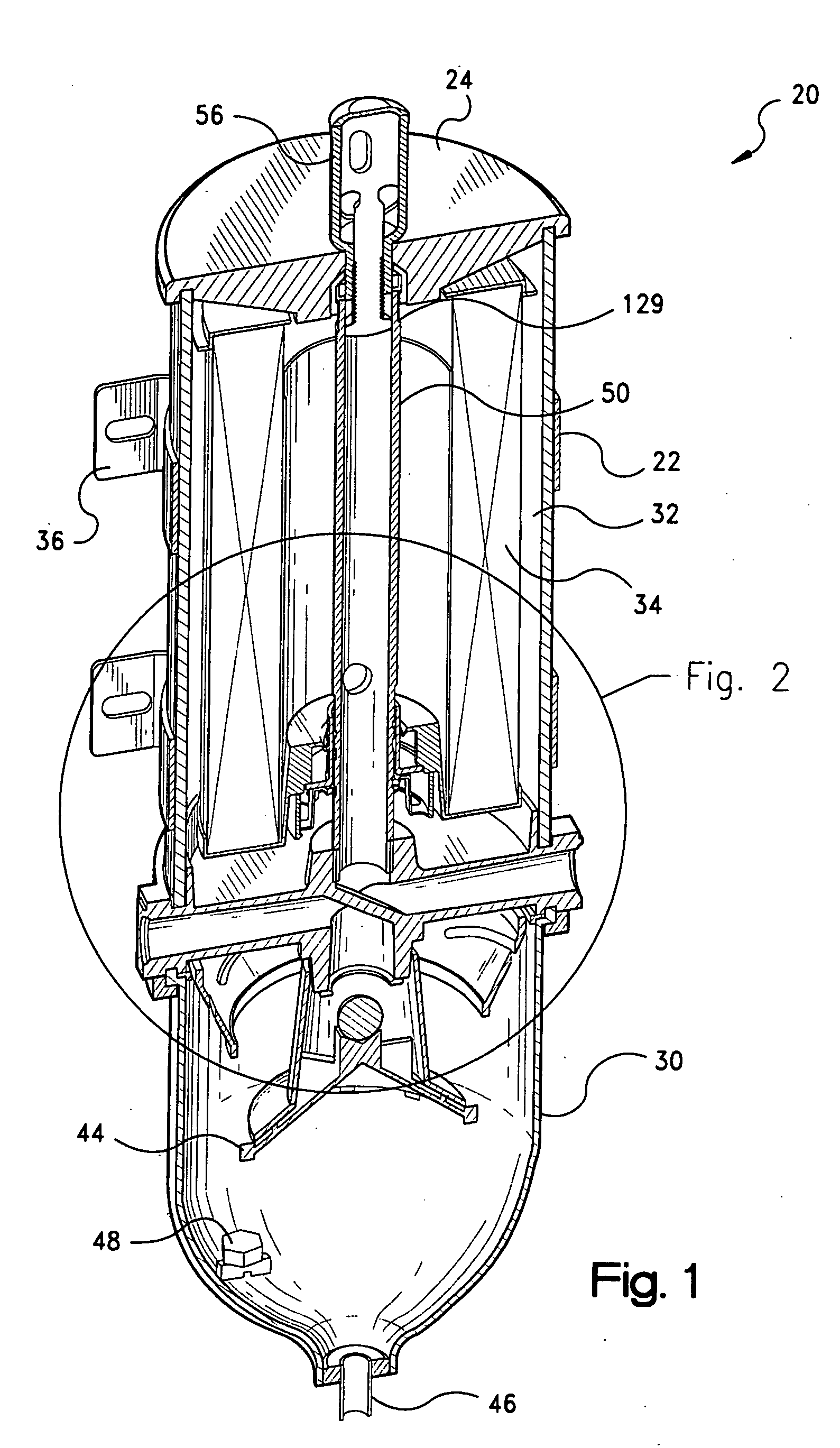

[0076] A filter element 140 is mounted within the housing portions and comprises a ring-shaped media circumscribing a central cavity 141. Filter element 140, similar to filter element 92 in the first embodiment, can be any filter media appropriate for the particular application, and includes an upper or first annular end cap 142 and a lower or second annular end cap 143. The end caps 142, 143 are bonded to the media in an appropriate manner. The filter element 140 is supported on a series of flanges or ribs 144 integral with the lower housing portion.

[0077] A pump assembly, indicated generally at 148, is also mounted between the housing portions, and includes an electric pump 150 with integrated drive motor, and an upper cap or cover 152 having an electrical connection 154 for the motor. Pump 150 can be any conventional type of pump appropriate for the particular application. One such pump is available from AIRTEX PRODUCTS of Fairfield, Ill., with a flow rate of 110 Liters / Minute at...

second embodiment

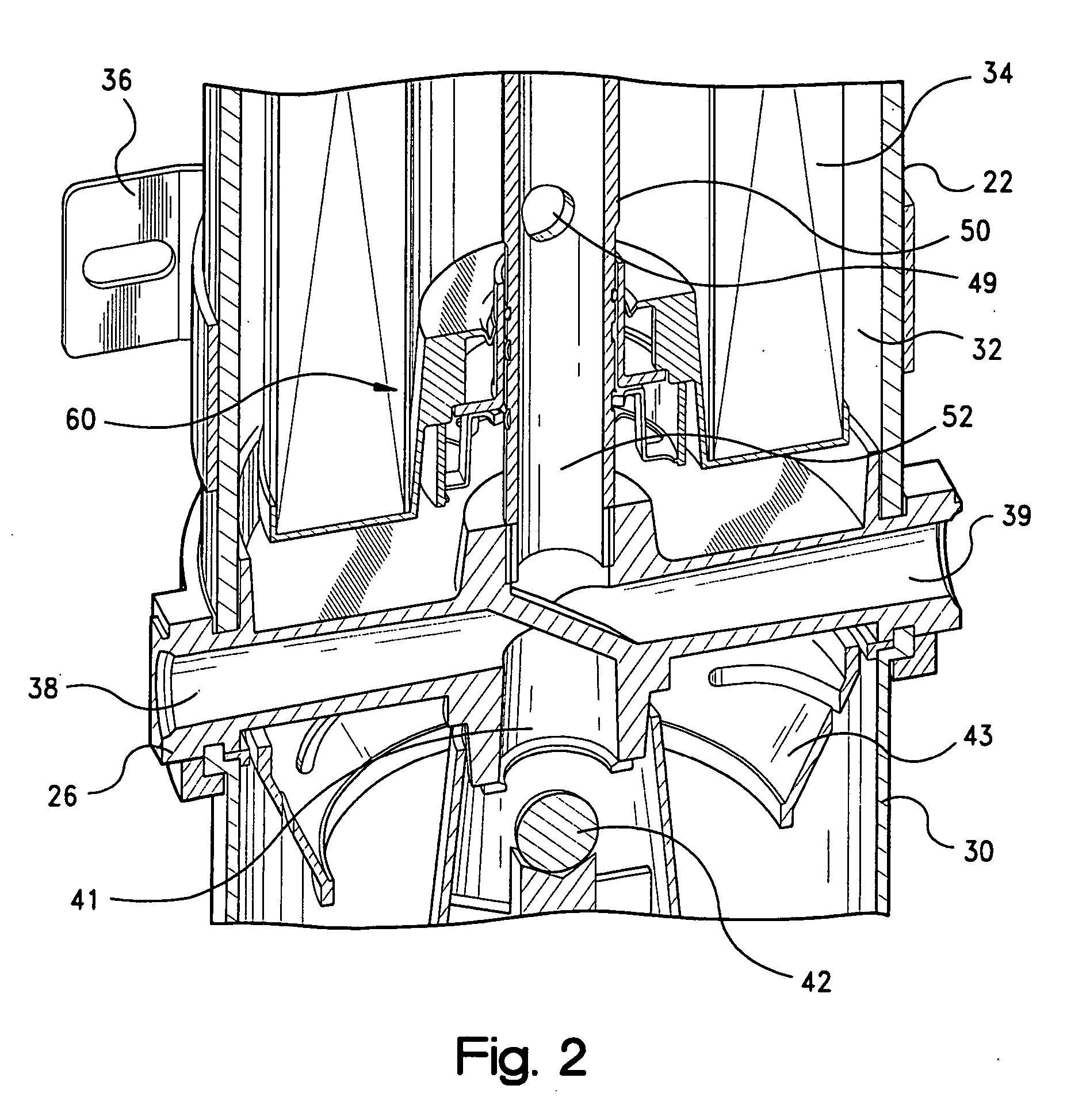

[0103] As described above with respect to FIG. 16, the keys 194 of the key device, and the tabs 76 and slots 78 on the latch device 64 are arranged such that when the filter element is inserted into the housing, at least a portion of the keys can fit through the slots 78. The axially longer and radially thinner portions 240 of the keys fit through the slots 78 in the latch device and engage the engagement surface 86 of the sleeve 84 on the valve device. Similar to the second embodiment, as the element is inserted upwardly into the housing, the keys press against the sleeve 84, and cause the latch device to bend and pull the fingers 80 radially outward from the inlet pipe. As the fingers are pulled outward, the distal ends 82 of the fingers are pulled outward from locking groove 167, thus releasing the latch device and allowing the latch device to slide axially upward along the inlet pipe.

[0104] Simultaneously with the fingers 80 being released, the radially wider and axially shorter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com