Metalwood type golf clubhead having an improved structural system for reduction of the cubic centimeter displacement and the elimination of adverse aerodynamic drag effect

a golf clubhead and metalwood technology, applied in the field of golf clubheads, can solve the problems of reducing the effective ball-contact hitting area of the shaped clubhead, and the subtle changes of the clubhead and the expected performance of the larger metalwood clubhead, so as to reduce the negative drag effect of the conventional shaped clubhead and reduce the cubic centimeter displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

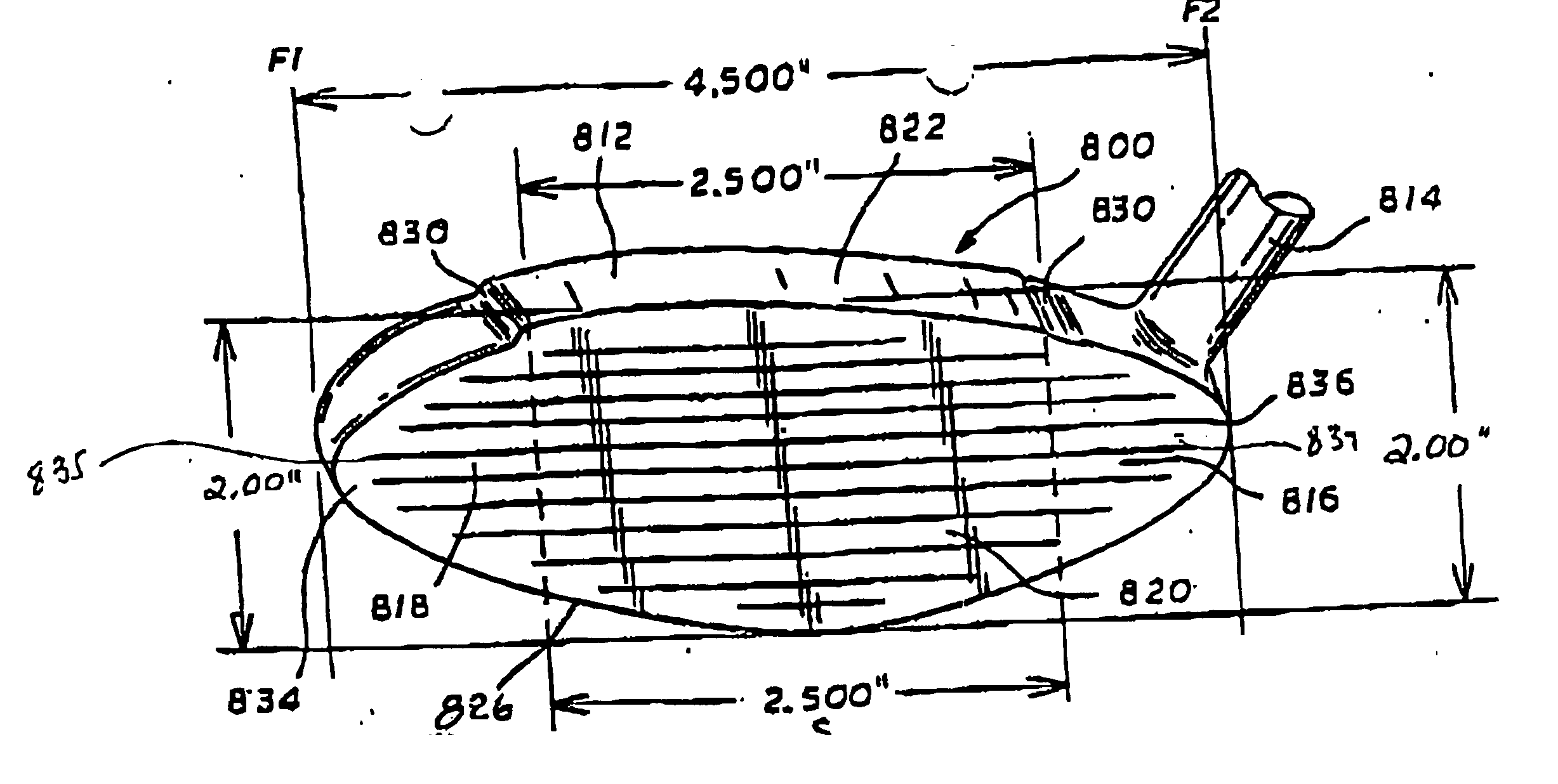

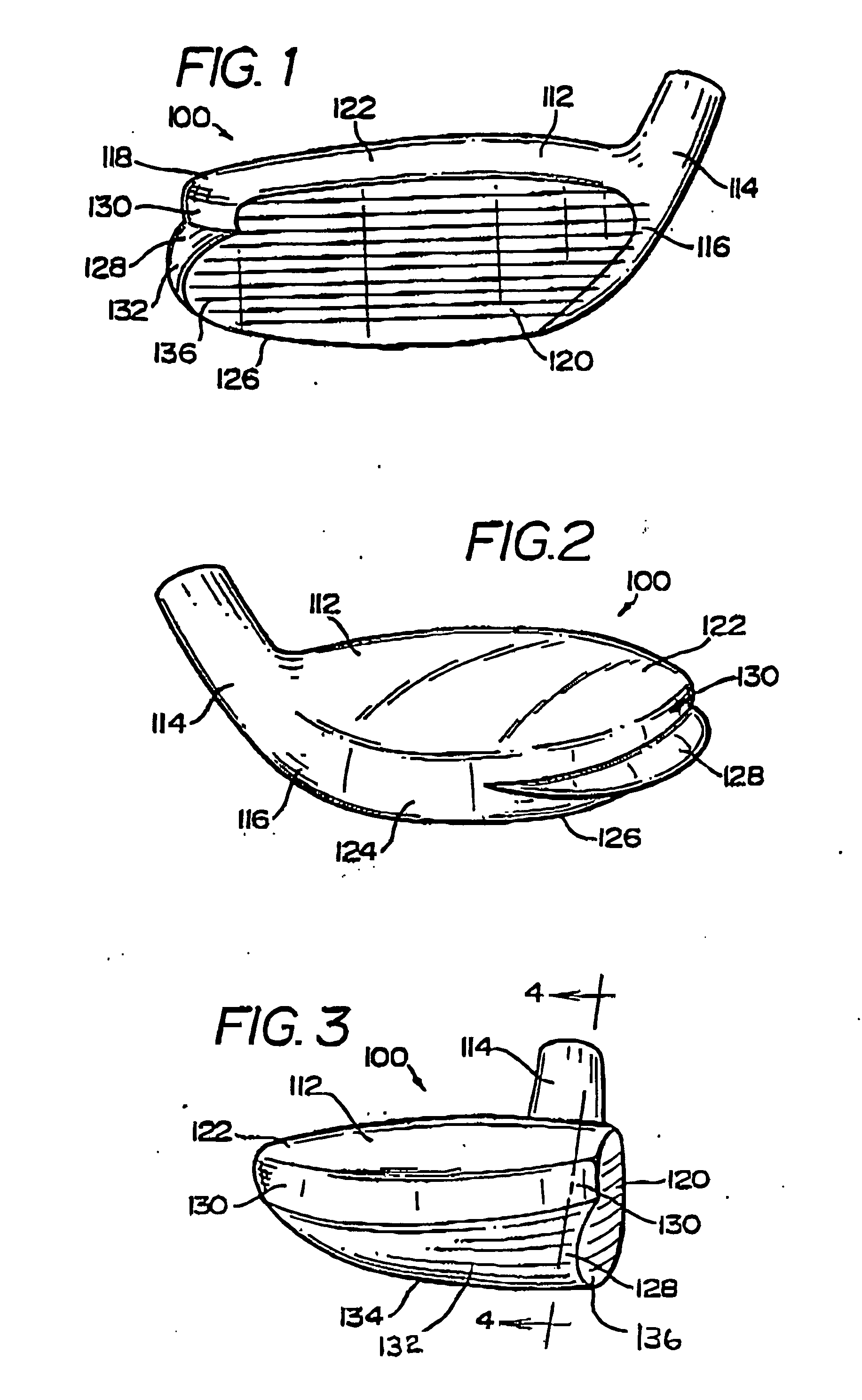

[0091]FIGS. 1-4 show a golf clubhead 100 in accordance with the present invention including a clubhead body 112, hosel 114, heel 116, toe 118, ball-striking clubface 120, upper surface 122, rear surface 124 and bottom sole 126. A single reinforcing and stabilizing member 128 having an aerodynamic shape, is located coincident with or adjacent to the bottom surface 126 of the clubhead 100 and which wraps partially around the peripheral sides 130 of the clubhead 100. The member 128 includes upwardly curving, convex parabolic surface 132 including a lower surface 134 extending upwardly and coincident with the bottom sole 126 of the clubhead 100. In this embodiment, the member 128 has an additional front ball-striking surface 136 which is laterally coincident with the lower section of the ball-striking clubface 120, thereby enlarging the ball contact surface of 120 and providing a greater margin for error when golf balls are struck away from the center of the ball-striking clubface 120 t...

second embodiment

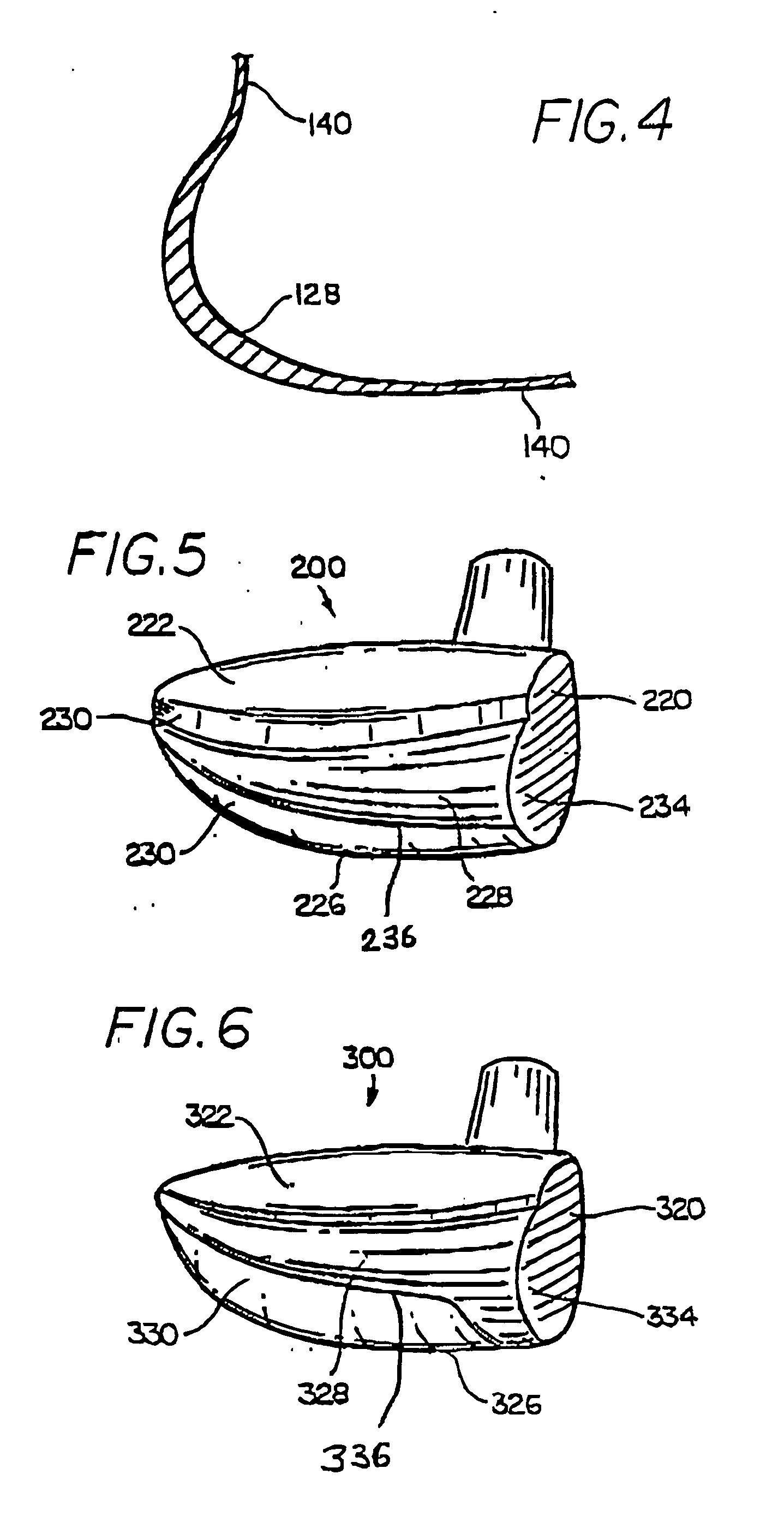

[0093]FIG. 5 illustrates a golf clubhead 200 of the present invention. In this embodiment a reinforcing and stabilizing member 228 includes a ball-striking surface 234 which is parallel to but does not align fully with clubface 220 with a non-coincident raised bottom surface 236 is centrally located on the side wall 230 of the clubhead 200 approximately midway between the crown surface 222 and the bottom 226 of the clubhead 200.

third embodiment

[0094]FIG. 6 illustrates a golf clubhead 300 of the present invention wherein a reinforcing and stabilizing member 328 includes a larger ball-striking surface 334 which is coincident with and covers a larger portion of clubface 320. The reinforcing and stabilizing member 328 has a non-coincident lower surface 336 raised above the bottom surface 326 of the club head 300. The reinforcing and stabilizing member 328 is also located adjacent the top surface of side wall 330 adjacent the crown surface 322 of the clubhead 300. For lower ball flight trajectory, a larger ball-striking surface 334 is coincident with a greater portion of the front of ball-striking clubface 320.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com