High frequency pulse width modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It will be understood by those skilled in the art that the present invention can be implemented in a number of different ways, within the scope of the claims appended hereto. A presently preferred embodiment of the invention will now be described below.

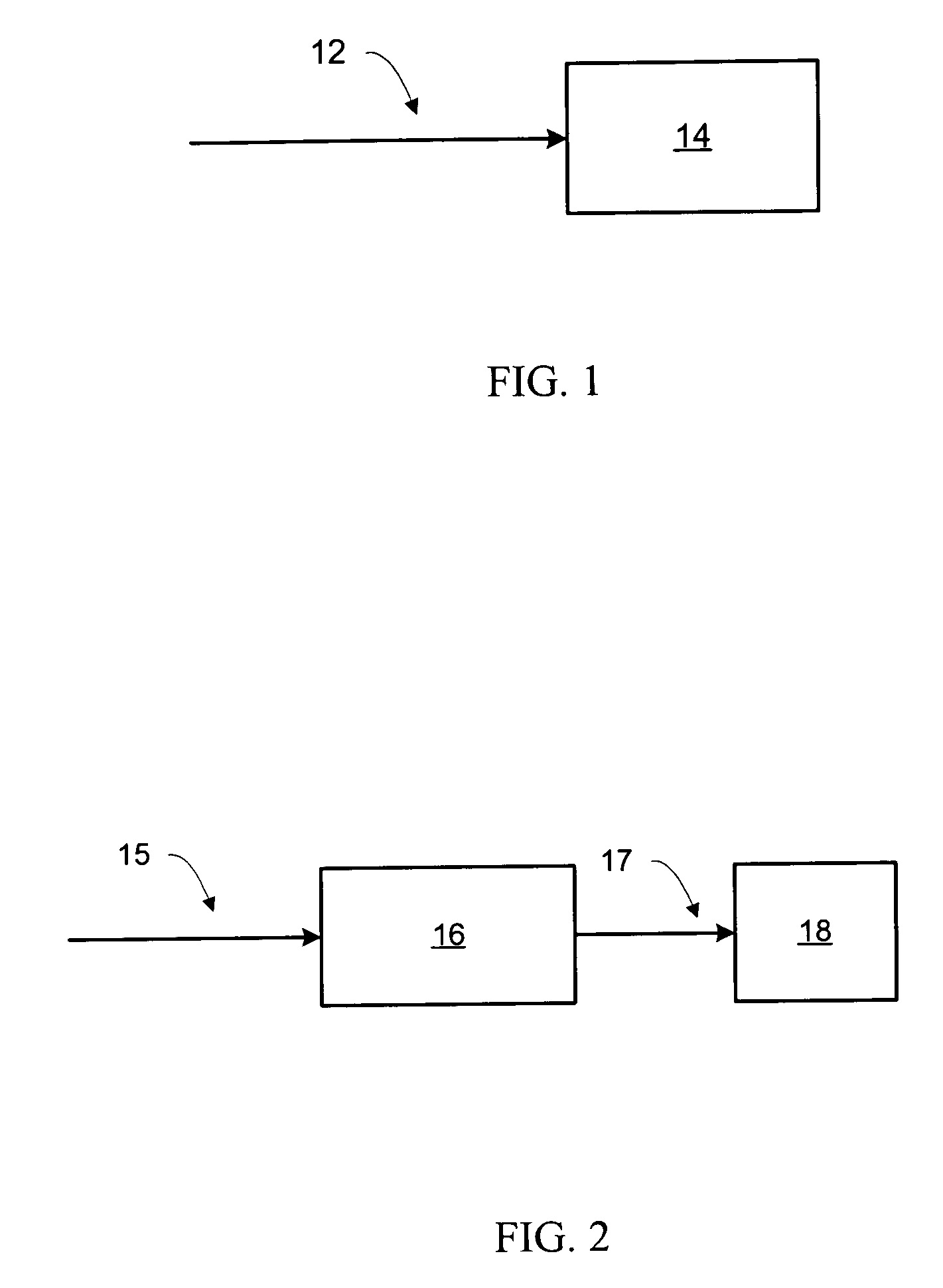

[0037] An electrical device 14 of the prior art is shown in FIG. 1. The operational intensity of electrical device 14 is controlled directly by DC input signal 12. Control is achieved by varying the DC input signal level. This approach to controlling operational intensity creates several problems. A significant amount of heat is generated which must be dissipated. Power inefficiencies occur and electronic and microelectronic components tend to be harmed by variation of voltage levels. As adoption of electronic and microelectronic components has become extremely widespread, the increased electronic and microelectronic failure rate associated with using DC input signals to directly control the operational intensity of electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com