Ballet pointe shoe

a technology of ballet shoes and pointe shoes, applied in the field of ballet shoes, can solve the problems of asymmetric ballet pointe shoes, a large strain and injury rate, and few dancers being able to practice their profession, and achieve the effect of prolonging the life of the shell of the ballet sho

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

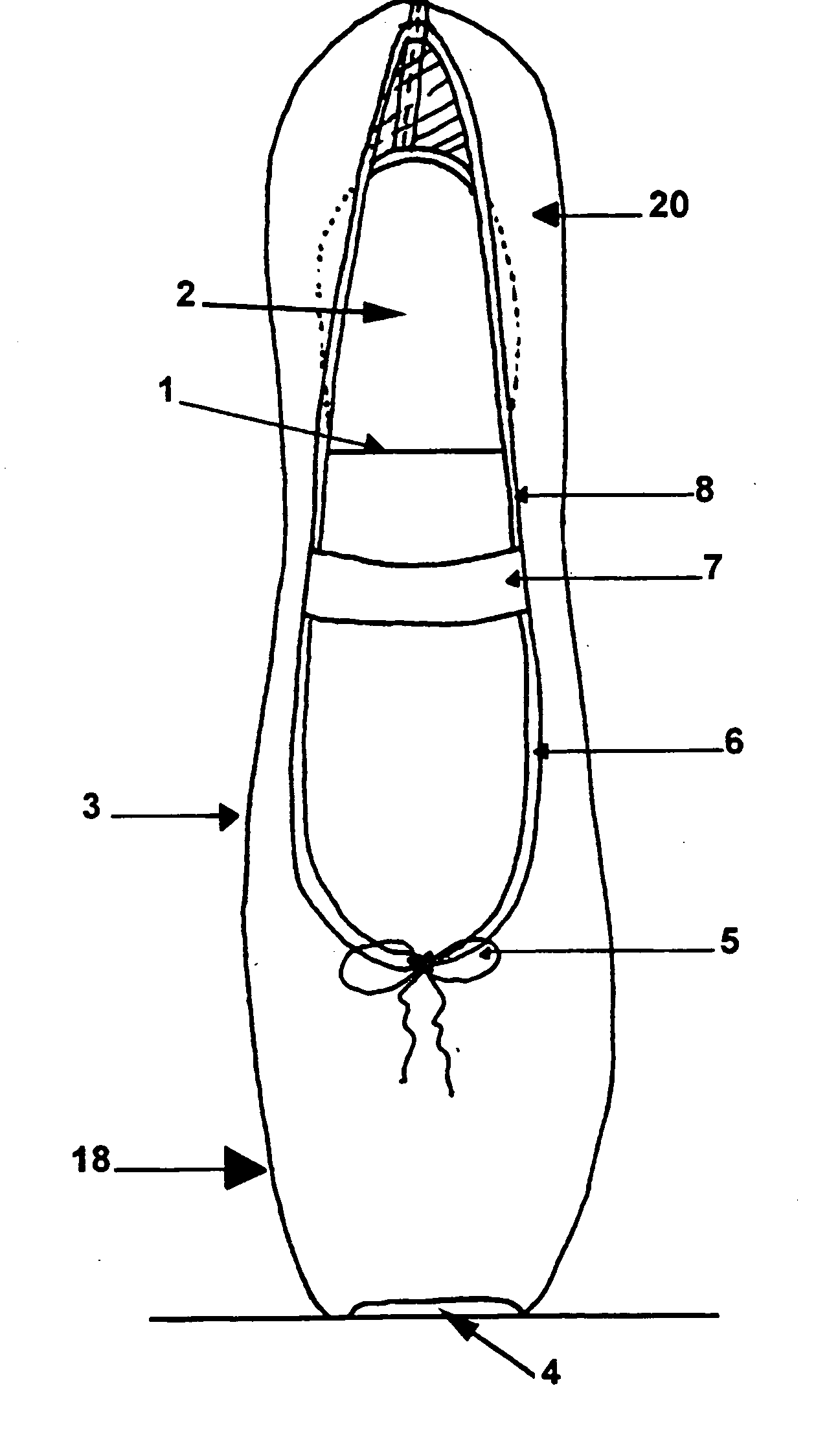

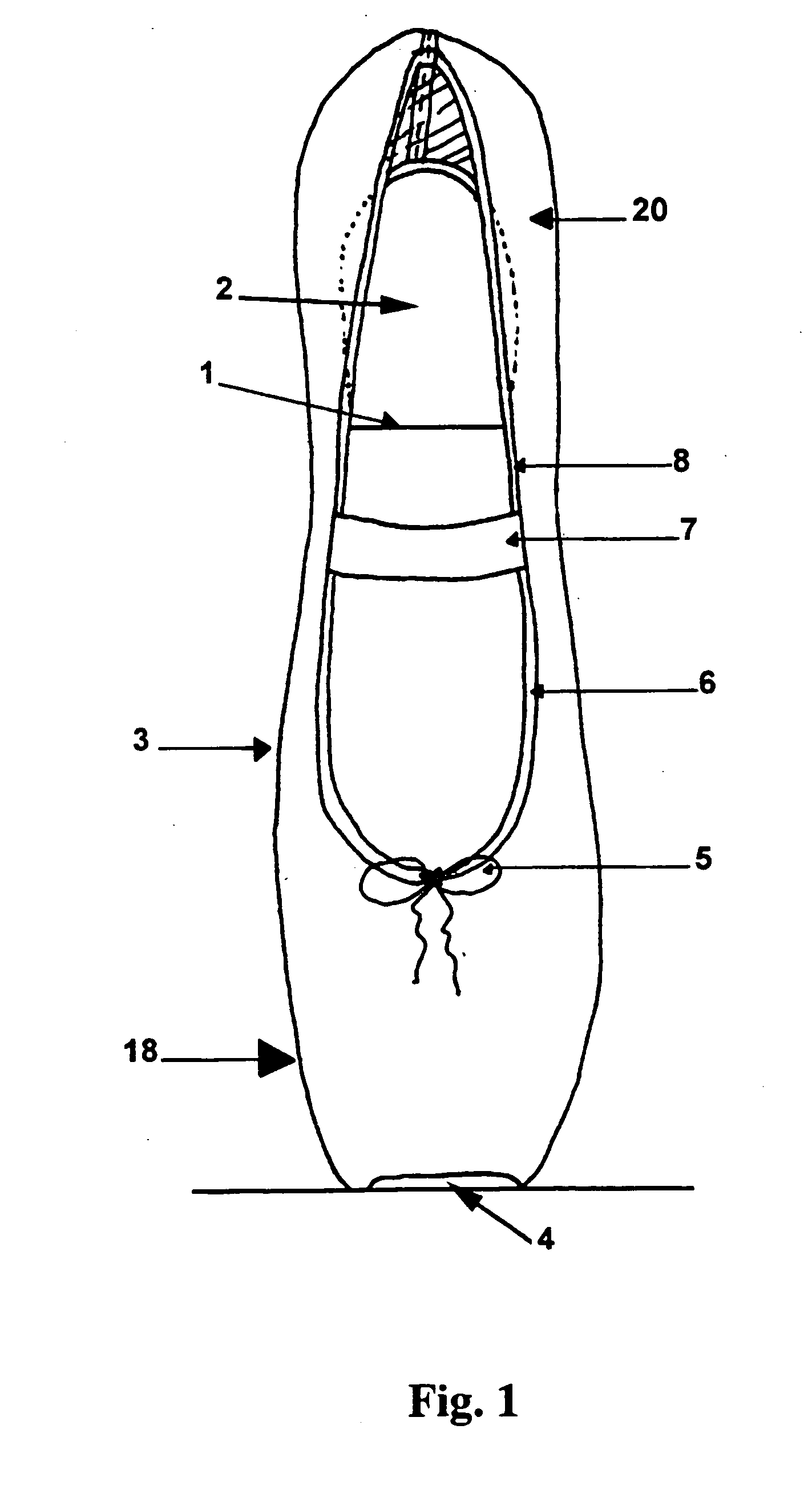

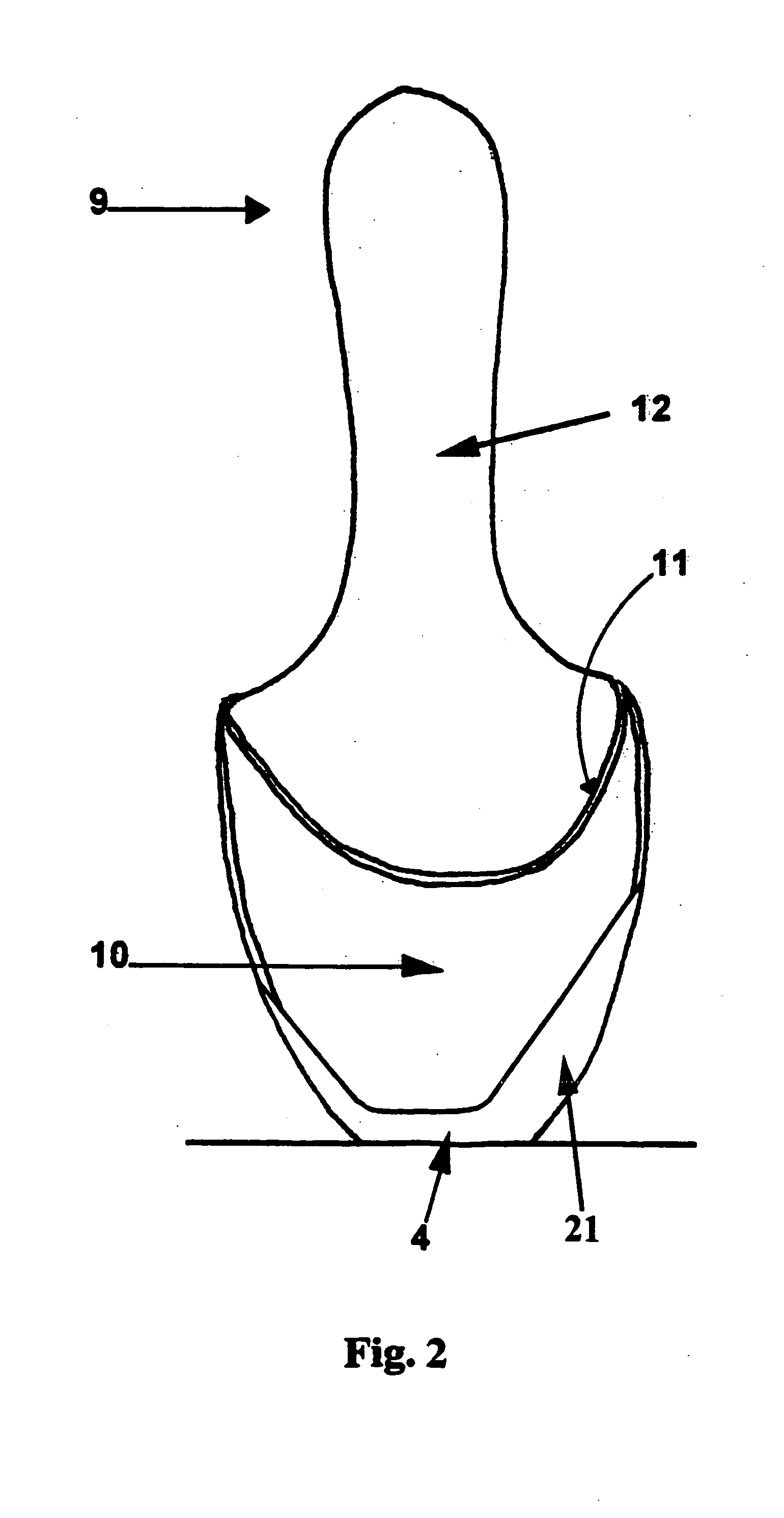

[0020] The present invention will now be illustrated further with respect to the drawings. Although the description and drawings are made with reference to a ballet shoe, it is to be understood that the present invention encompasses any pointe shoe.

[0021] The primary cause of foot problems experienced by ballet dancers when en pointe is the fact that the line across the distal tips of the dancer's toes is neither straight nor at right angles to a longitudinal centerline of the dancer's foot. Consequently, the entire vertical force of the dancer's weight is usually concentrated in the one or two longest toes of the foot, resulting in extreme discomfort if not pain and injury to the dancer's foot. The dominant human foot type has the second toe longer than the first toe. Thus, when a dancer is in pointe position, the weight commonly is concentrated on the big toe and the adjacent toe. This is not always the case, though, there being a wide variation in the configuration of toes among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com