Techniques for curvature control in power transistor devices

a technology of power transistors and curvatures, applied in semiconductor devices, semiconductor/solid-state device details, electrical equipment, etc., can solve problems such as maximum heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention will be described below in the context of processing an exemplary power transistor device, namely a diffused metal oxide semiconductor (DMOS) device. However, it is to be understood that the present invention is not limited to use with DMOS devices. Rather, the invention is more generally applicable to the processing of any power transistor device, especially those power transistor devices requiring heat removal.

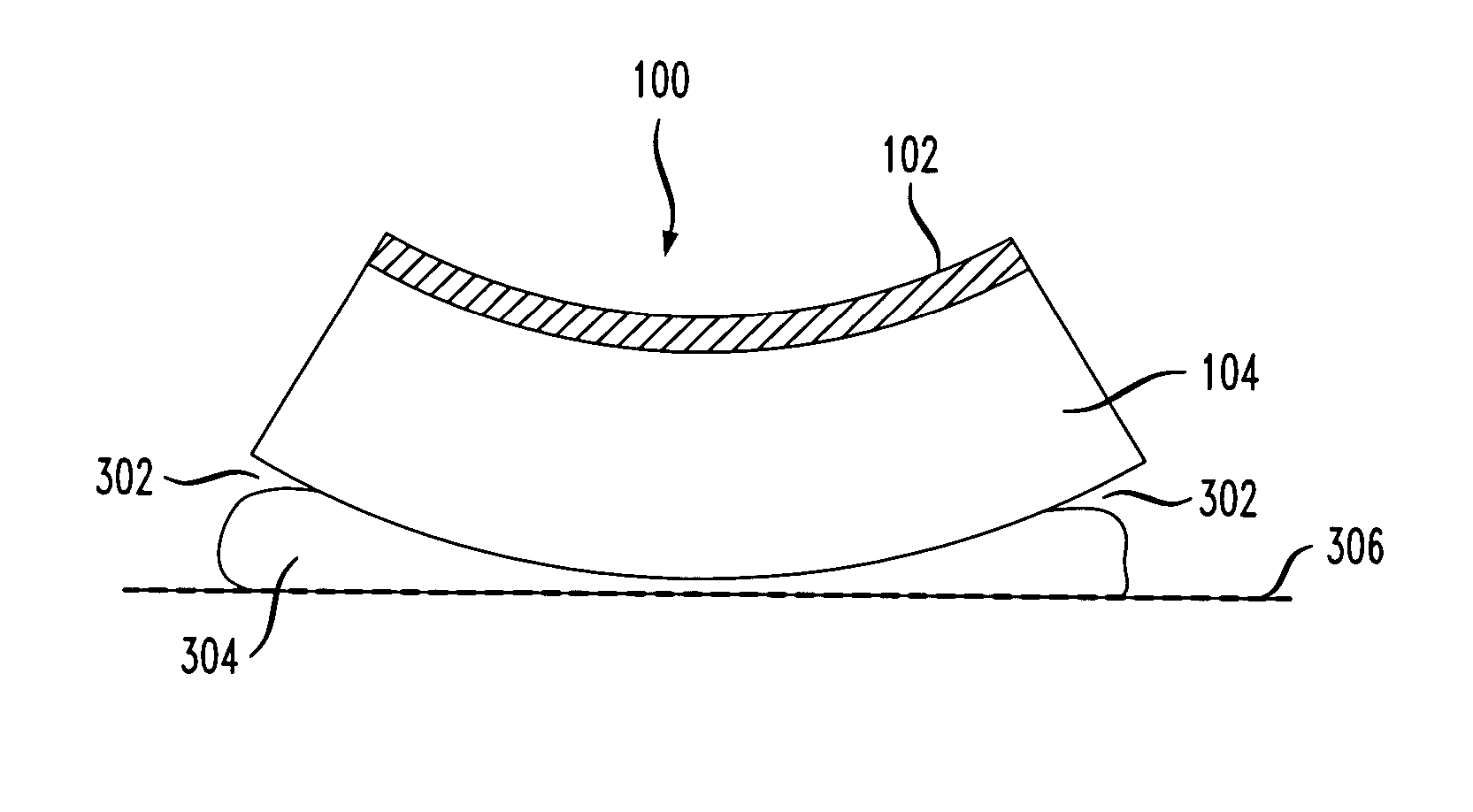

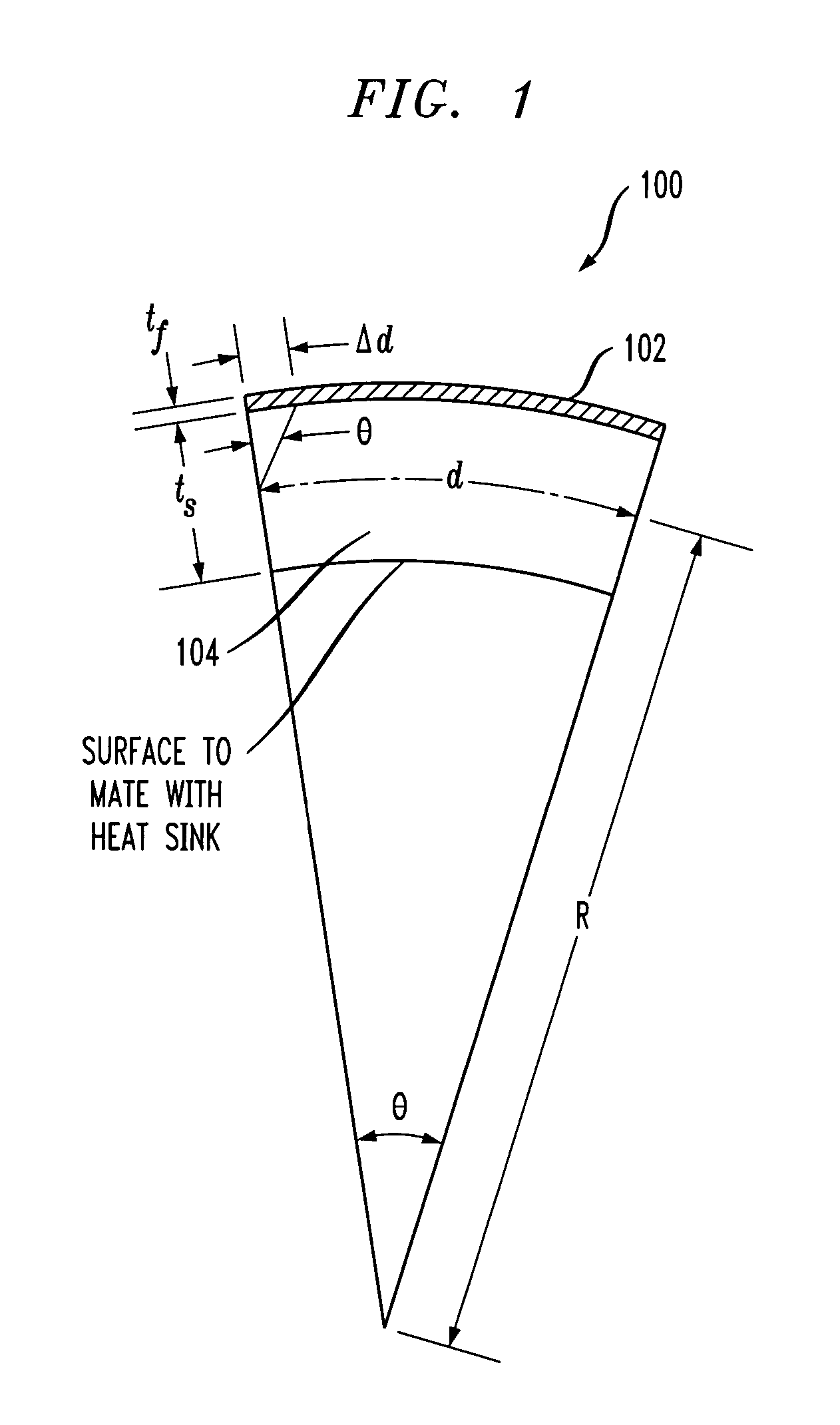

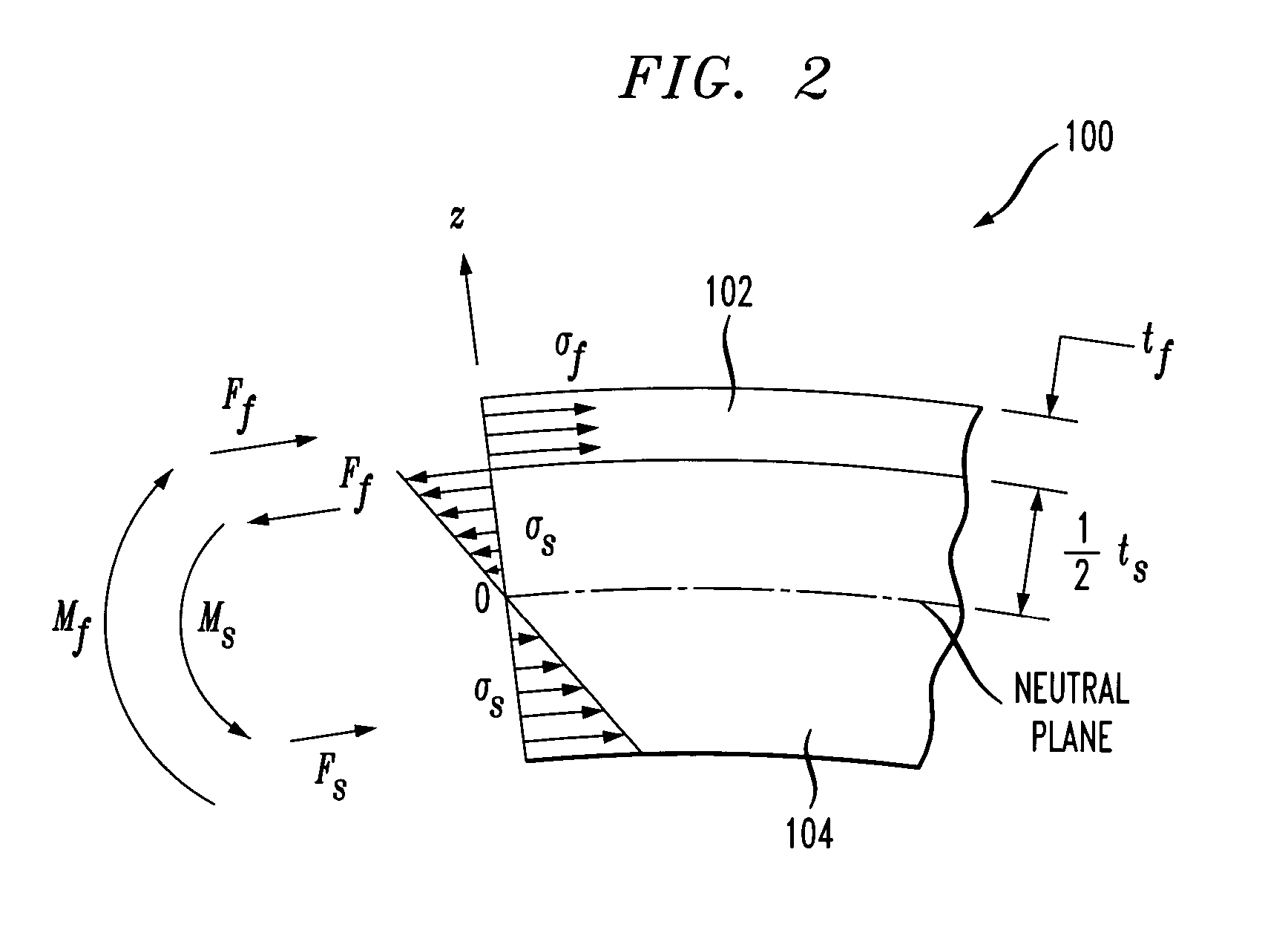

FIG. 1 illustrates an exemplary DMOS device 100 after thinning of the device substrate has been performed. DMOS device 100 comprises DMOS device film (hereinafter “DMOS film”) 102 on the surface of device substrate (hereinafter “substrate”) 104. DMOS device 100 may be, for example, part of an integrated circuit. As indicated in FIG. 1, substrate 104 may be mated with a heat sink (not shown) on a side of substrate 104 opposite DMOS film 102. DMOS film 102 represents accumulated layers that comprise DMOS device 100. For example, DMOS film 102 may includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com