Sectional flooring

a sectional flooring and sectional technology, applied in the field of sectional flooring, can solve the problems of reducing adhesivity, difficult removal of flooring, harmful to humans, etc., and achieve the effect of reducing the deformation caused by external factors such as moisture and facilitating assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

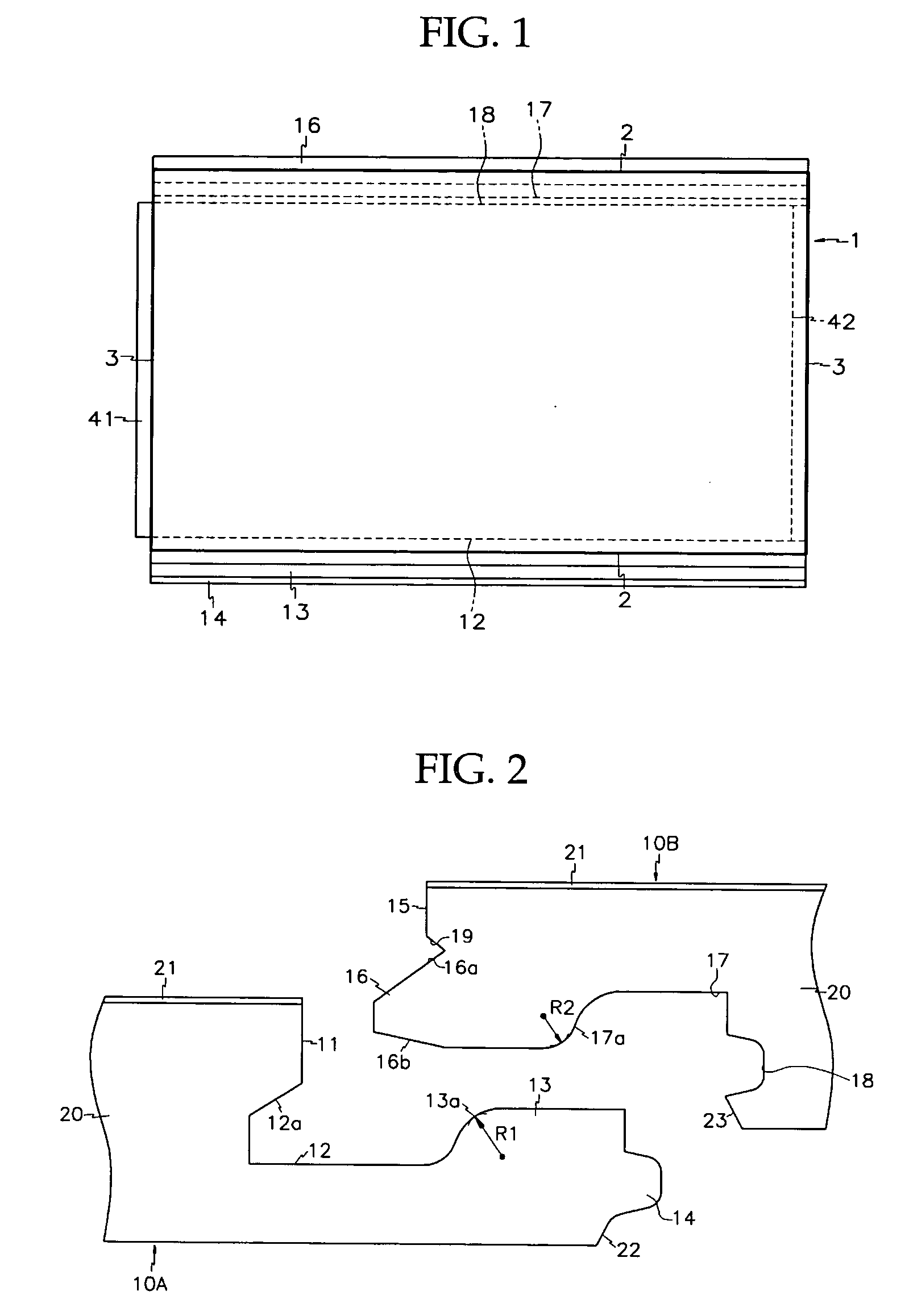

[0027]FIG. 1 is a plan view of sectional flooring according to an exemplary embodiment of the present invention.

[0028] With reference to FIG. 1, a flooring member 1 is a substantially rectangular board having a predetermined thickness and area. The flooring member 1 includes a pair of long sides 2 and a pair of short sides 3. The long sides 2 have a connection configuration that is different from the short sides 3, and the long sides 2 are interconnected with the long sides of other flooring units and the short sides 3 are interconnected with the short sides of other flooring units.

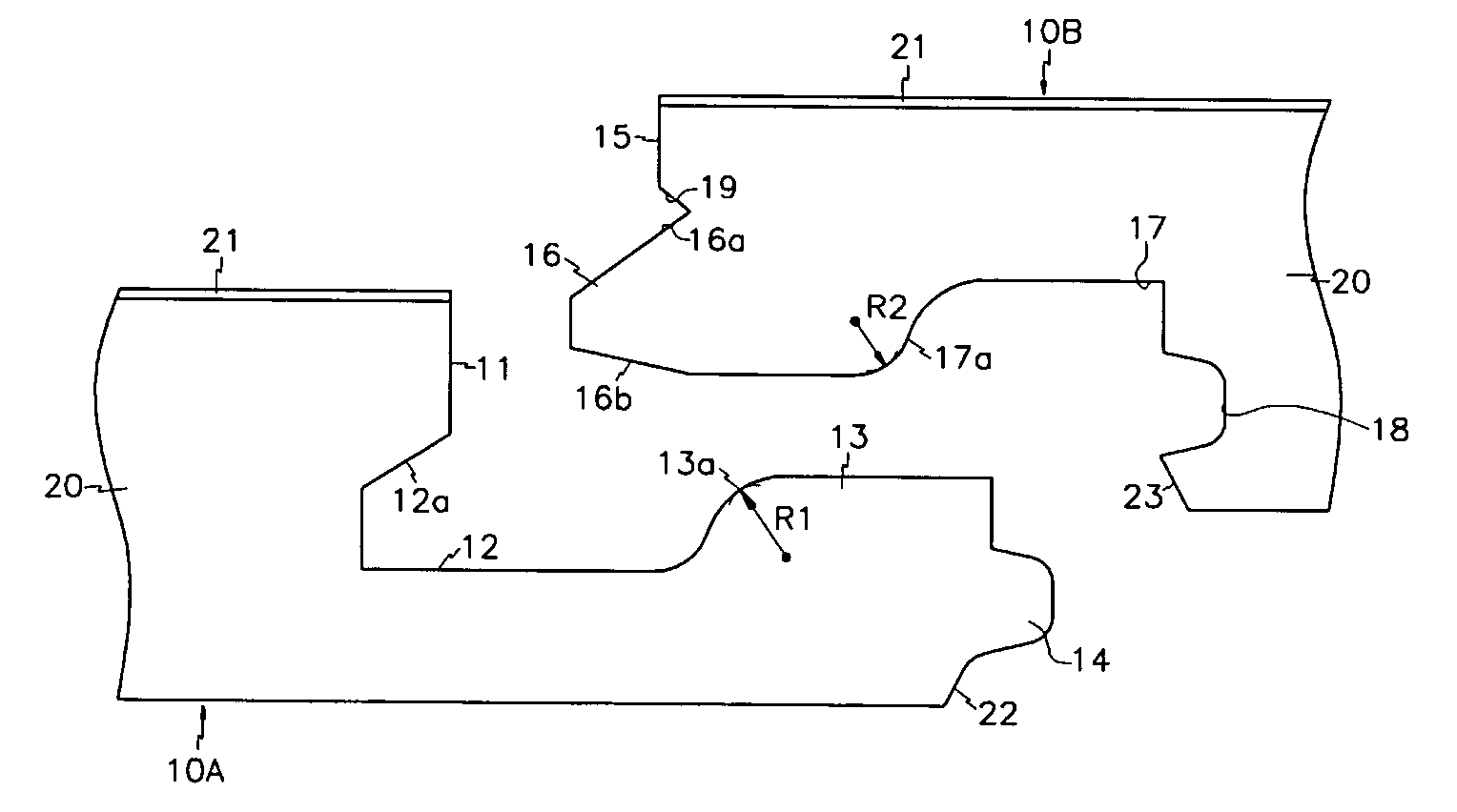

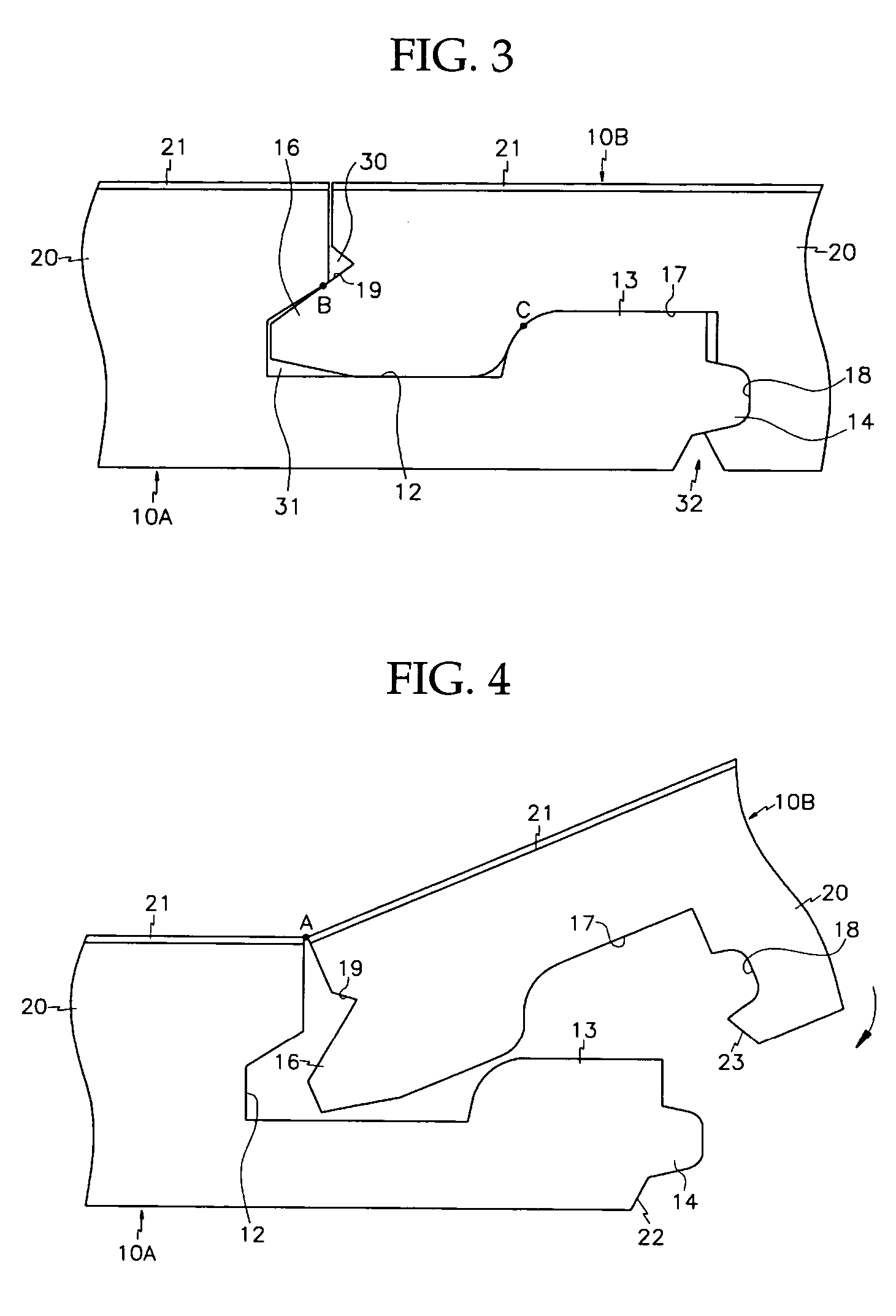

[0029]FIGS. 2 and 3 are views showing a pair of individual flooring units and their long side connection structure according to an exemplary embodiment of the present invention. Also, FIG. 4 is used to describe assembly of the flooring units.

[0030] A first flooring unit 10A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com