Expansion foam cavity filler and method

a filler and foam technology, applied in the field of expansion foam cavity filler and method, can solve the problem that polyethylene has almost no stretch, and achieve the effect of reducing vibration, noise, or fumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

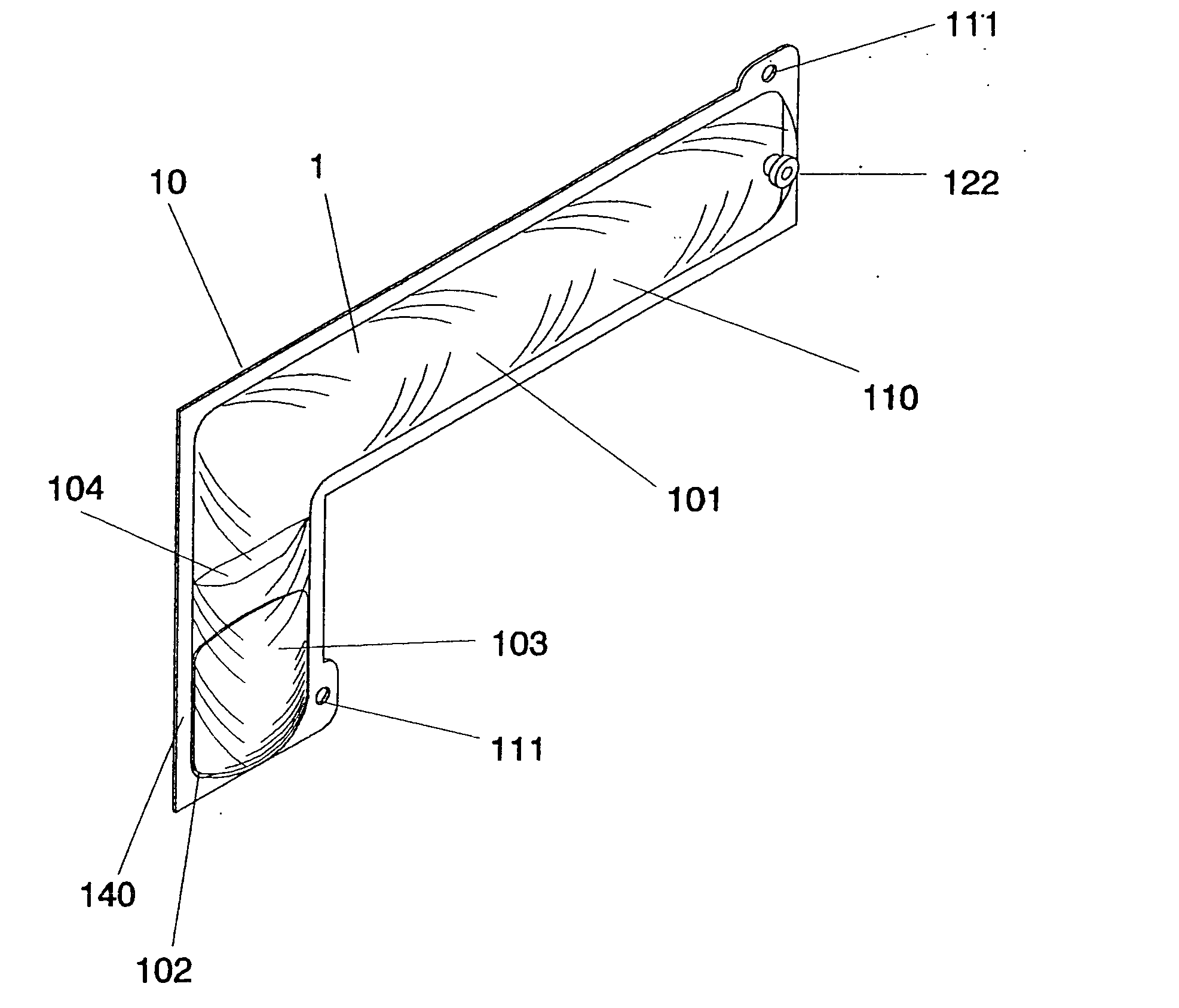

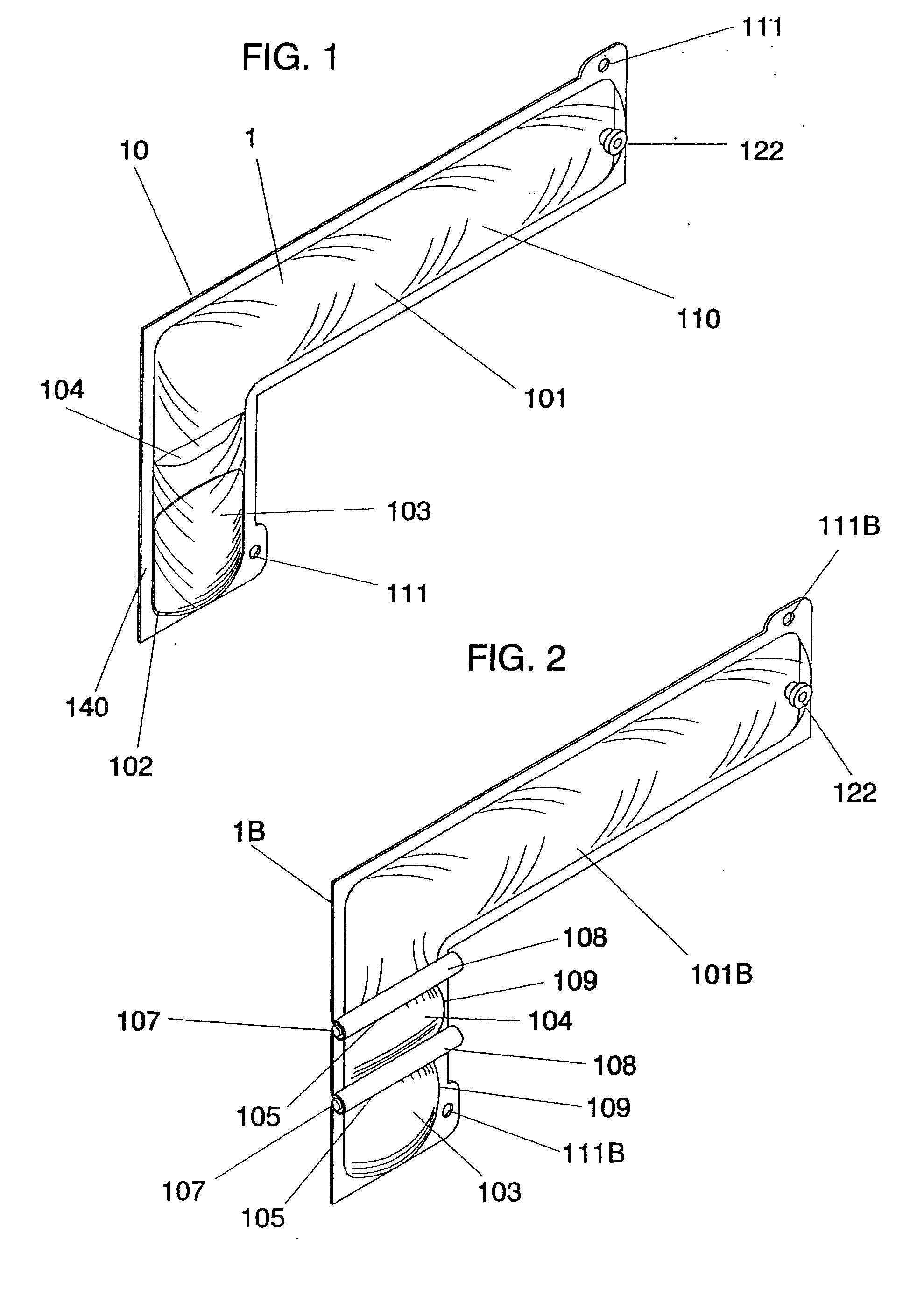

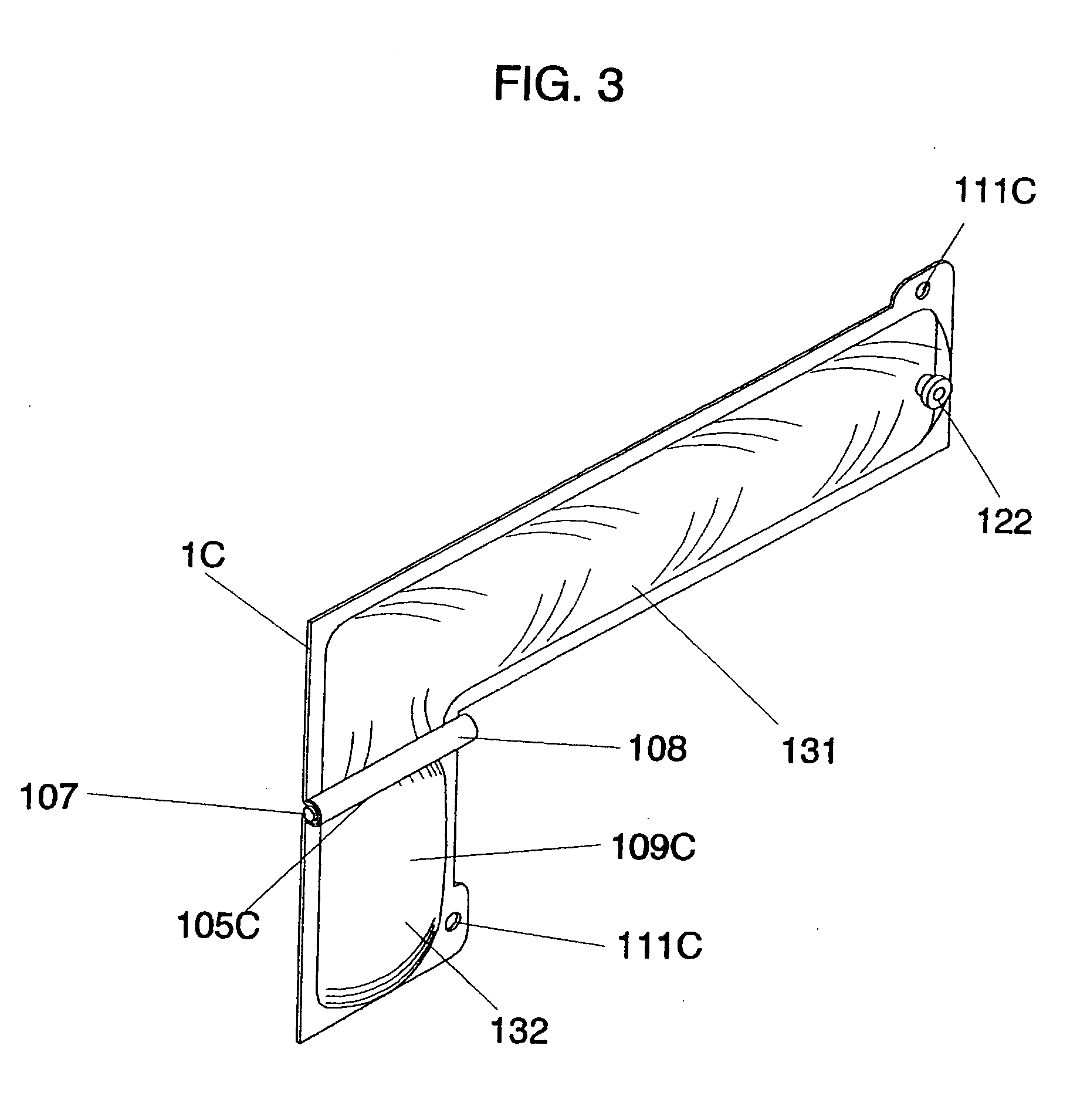

[0028] Referring to FIG. 1, in the preferred embodiment of the present invention, a cavity filler, an outer pouch 101, which is a flexible pouch, is fabricated in a given shape as desired for an intended application. The outer pouch 101 contains a first foam component 104. The outer pouch 101 may be composed of different types of material which affects characteristics such as, but not limited to, flexibility, stretch, density, toughness, strength, and adhesion of contents within the outer pouch 101 to the outer pouch 101.

[0029] The outer pouch 101 can be made from sheets of urethane in a thickness range from 1 thousandth to 10 thousands of an inch. Urethane provides a material that is very quiet in applications where the outer pouch 101 can be exposed to wind or other movement. This characteristic is particularly advantageous in vehicle applications and is ideal for automotive applications. A thickness of 3-4 thousandths of an inch appears to be ideal. FIGS. 6B and 6C show how the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com