Method for processing a semiconductor wafer

a technology of semiconductor wafers and processing methods, applied in semiconductor/solid-state device manufacturing, basic electric elements, electric devices, etc., can solve the problems that the future semiconductor manufacturing process may ultimately require more control and economic efficiency from the reactor, and achieve the effect of convenient removal and service, and convenient re-configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

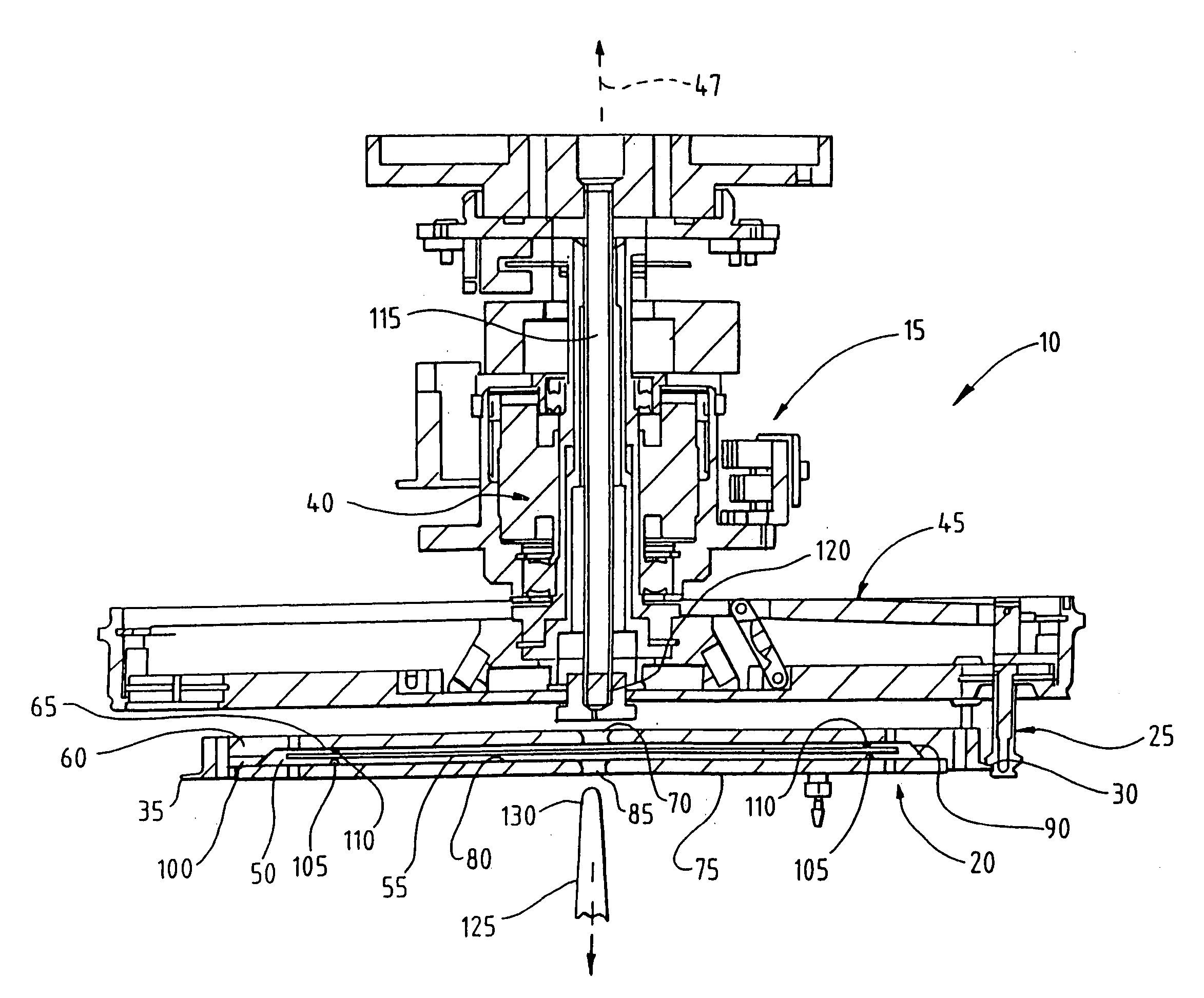

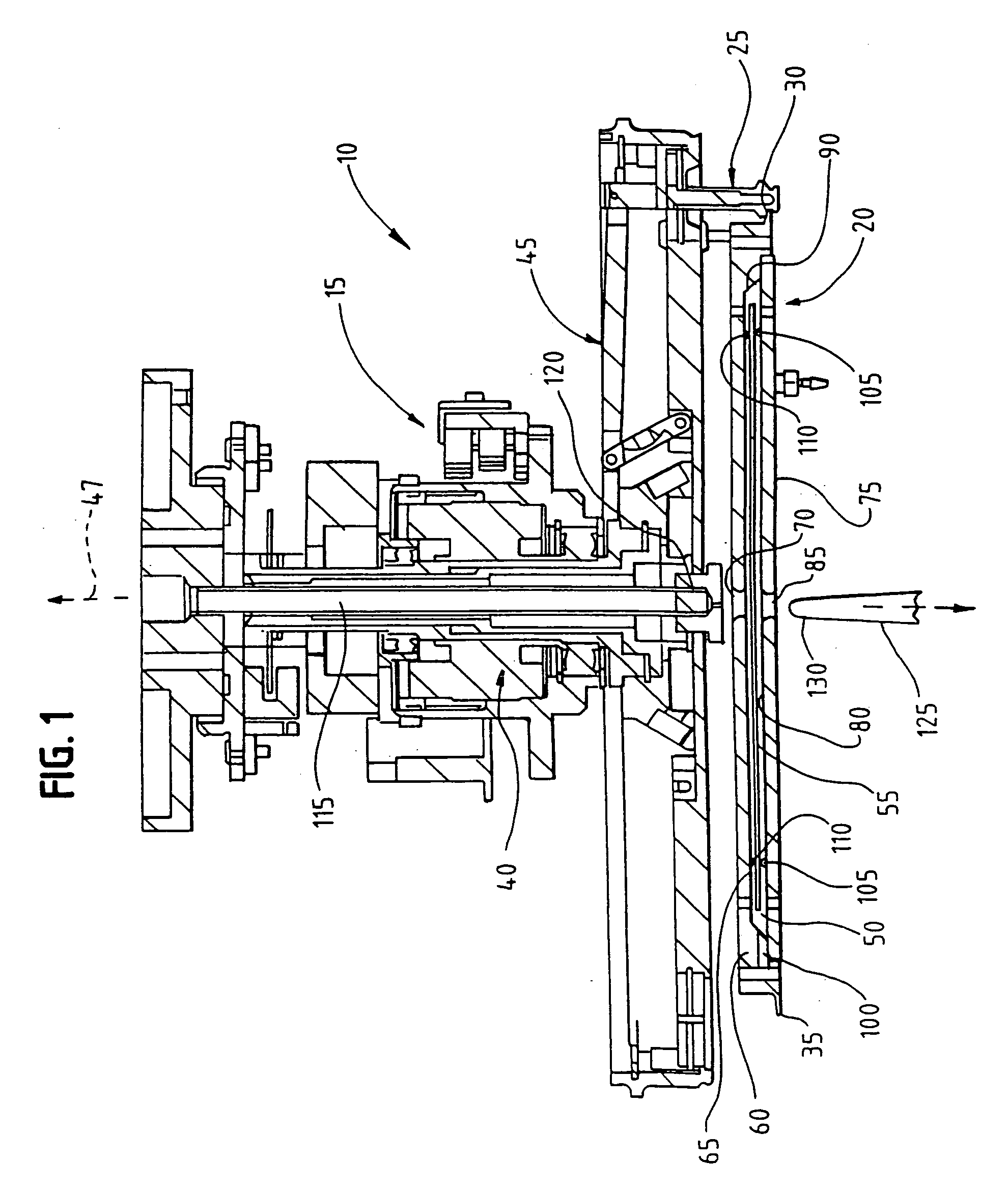

[0037]FIG. 1 is a cross-sectional view of one embodiment of a reactor, shown generally at 10, constructed in accordance with the teachings of the present invention. The embodiment of the reactor 10 of FIG. 1 is generally comprised of a rotor portion 15 and a microelectronic workpiece housing 20. The rotor portion 15 includes a plurality of support members 25 that extend downwardly from the rotor portion 15 to engage the workpiece housing 20. Each of the support members 25 includes a groove 30 that is dimensioned to engage a radially extending flange 35 that extends about a peripheral region of the workpiece housing 20. Rotor portion 15 further includes a rotor motor assembly 40 that is disposed to rotate a hub portion 45, including the support members 25, about a central axis 47. Workpiece housing 20 is thus secured for co-rotation with hub portion 45 when support members 25 are engaged with flange 35. Other constructions of the rotor portion 15 and the engagement mechanism used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com