Oil supply structure for continuously variable valve timing apparatus

a technology of oil supply structure and valve timing apparatus, which is applied in valve arrangement, pressure lubrication, machines/engines, etc., can solve the problems of reducing revolution and viscosity, and achieve the effect of reliable respons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention will now be described in detail with reference to the annexed drawings, where the present embodiment is not limiting the scope of the present invention but is given only as an illustrative purpose.

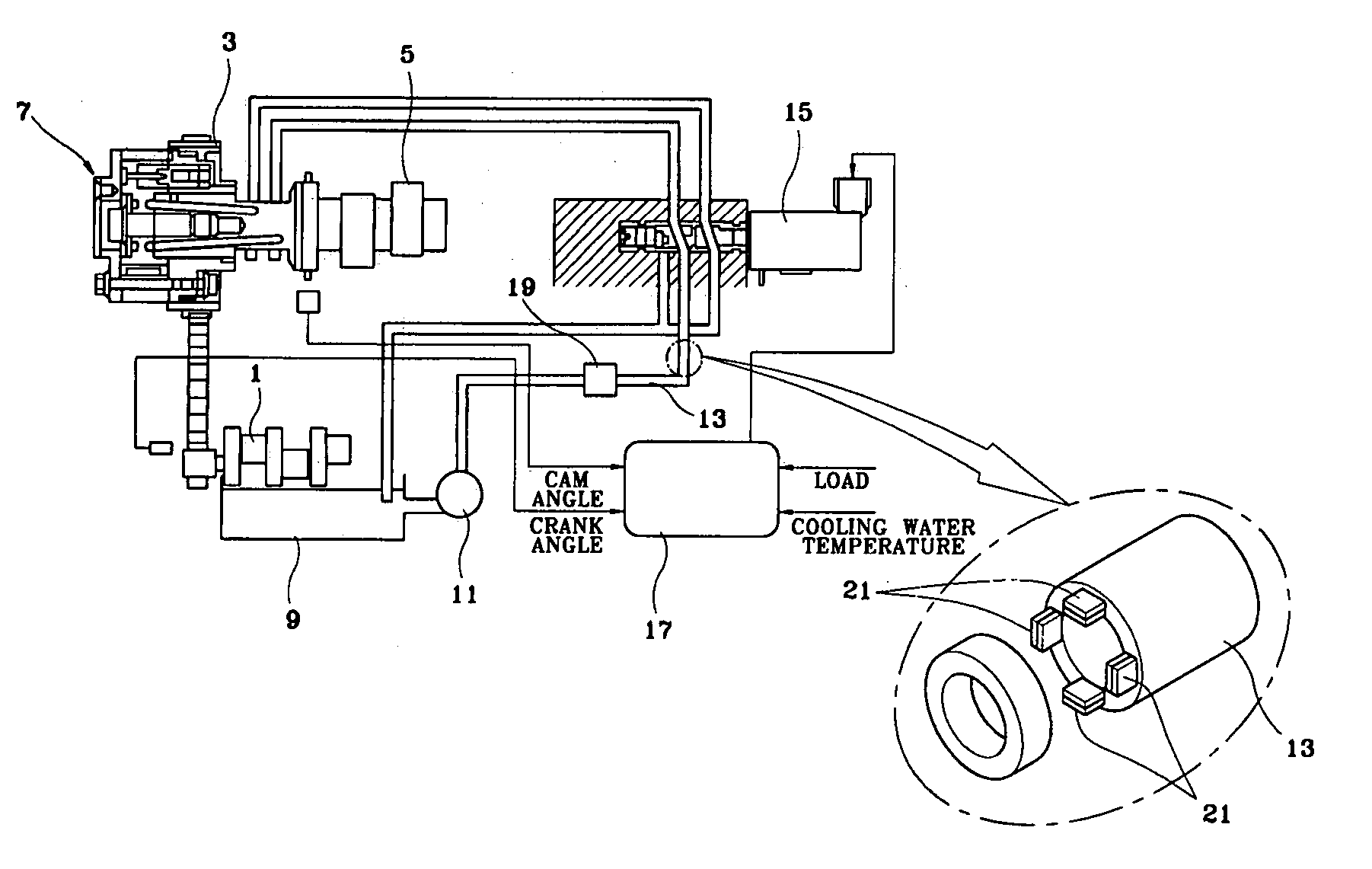

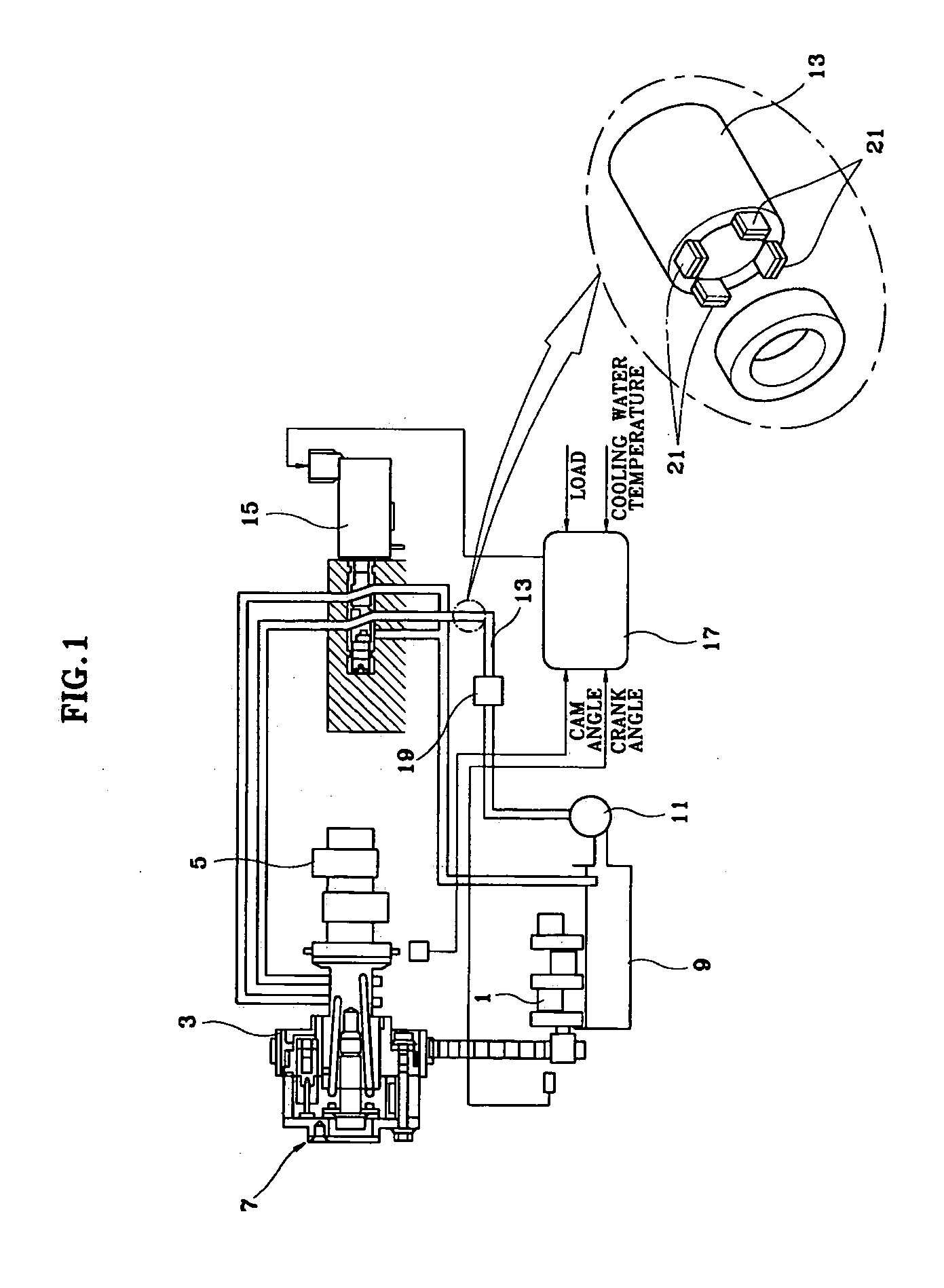

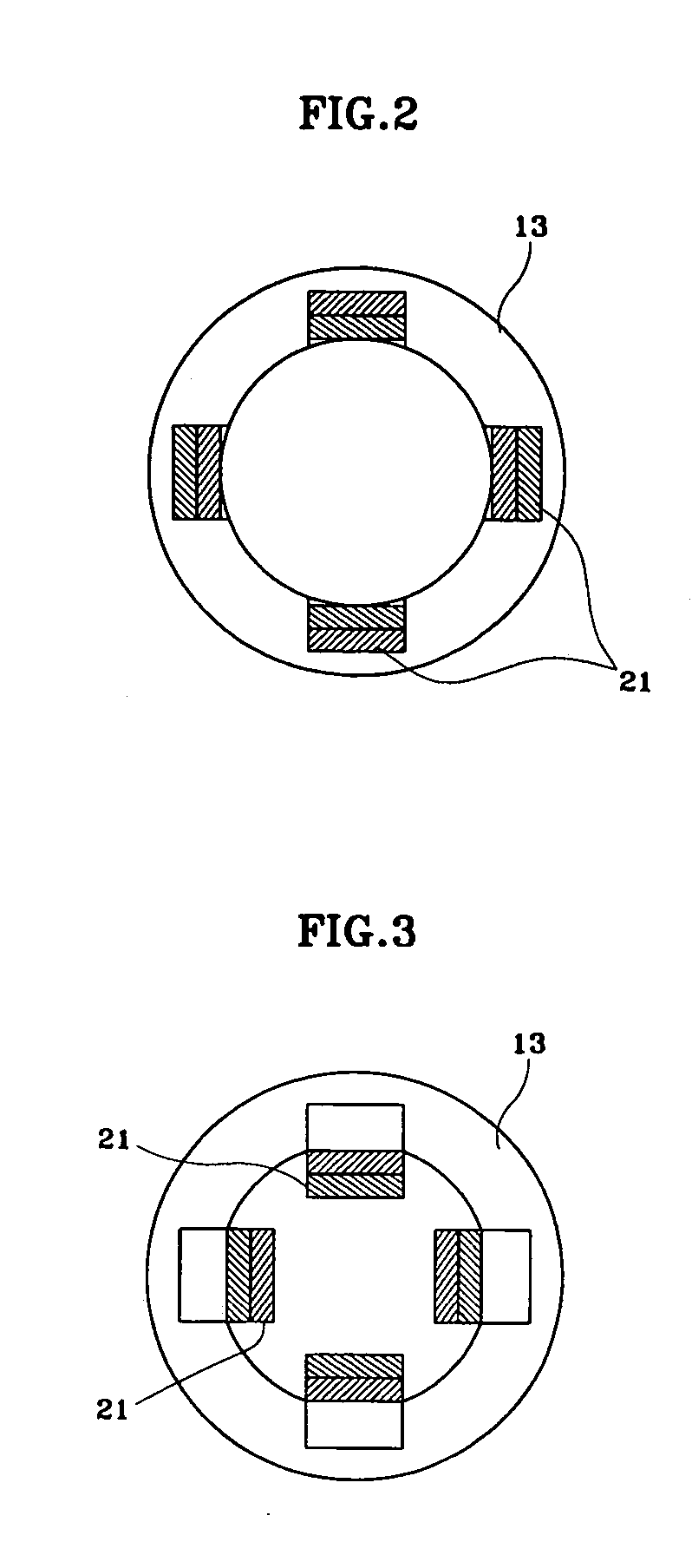

[0015] Referring to FIG. 1, an oil supply structure for a continuously variable valve timing apparatus according to a preferred embodiment of the present invention includes a rotor vane type actuator 7 mounted between a cam shaft sprocket 3 and a cam shaft 5 to enable a rotation of the cam shaft 5 relative to the cam shaft sprocket 3. Sprocket 3 is connected to a crankshaft 1 by a belt or chain. An oil control valve 15 is also disposed for receiving oil pumped by an oil pump 11 from an oil pan 9 via an oil supply pipe 13 and supplying the oil to the variable valve timing actuator 7 by adjusting an oil passage.

[0016] The oil control valve 15 is controlled by an electric signal provided from a controller 17 for receiving signals of var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com