Electropolishing solution and methods for its use and recovery

a technology of electrolysis solution and electrode, which is applied in the direction of electrolysis components, manufacturing tools, lapping machines, etc., can solve the problems of difficult and expensive disposal, surface finishing of metals, and shaping of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

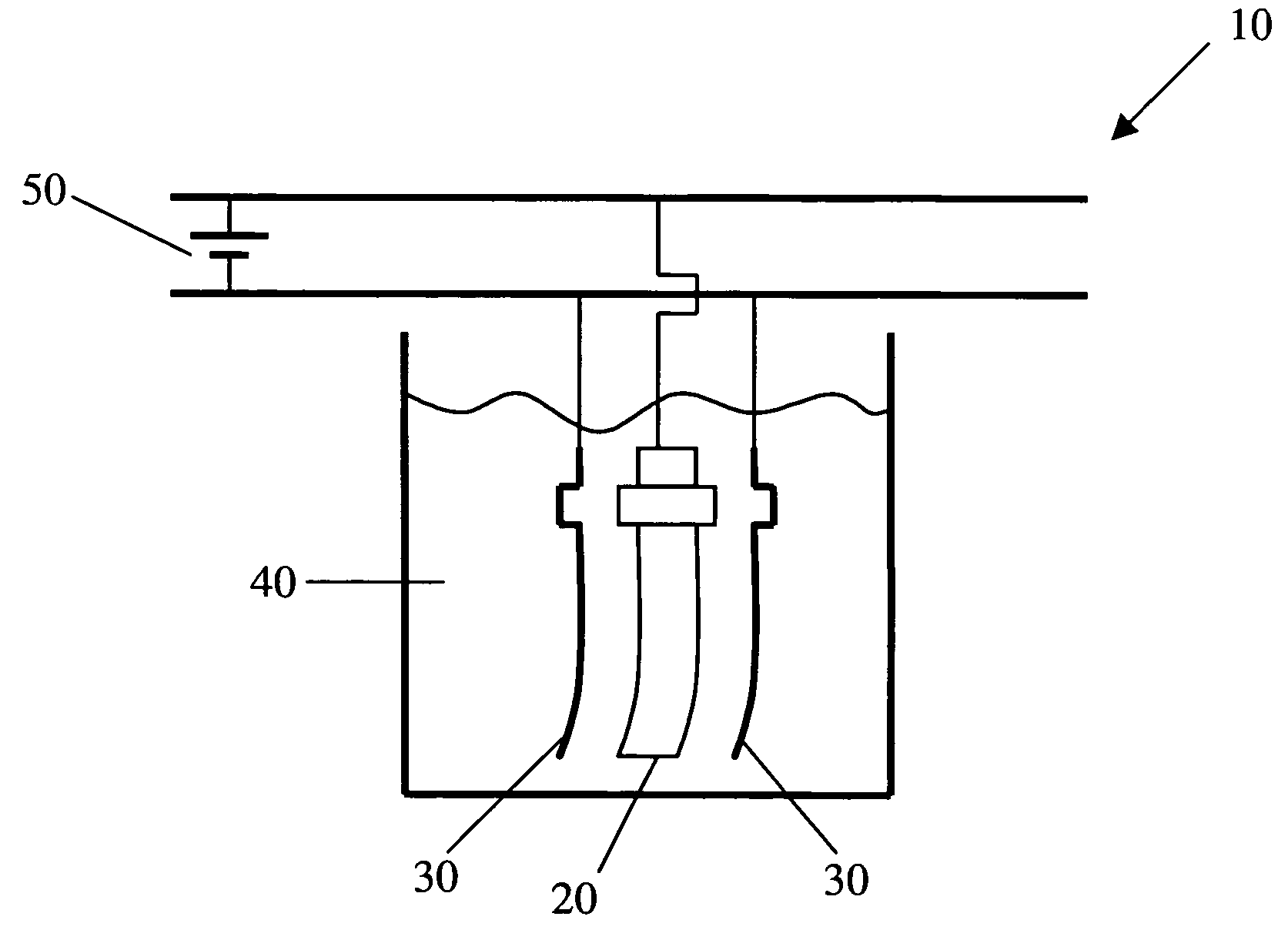

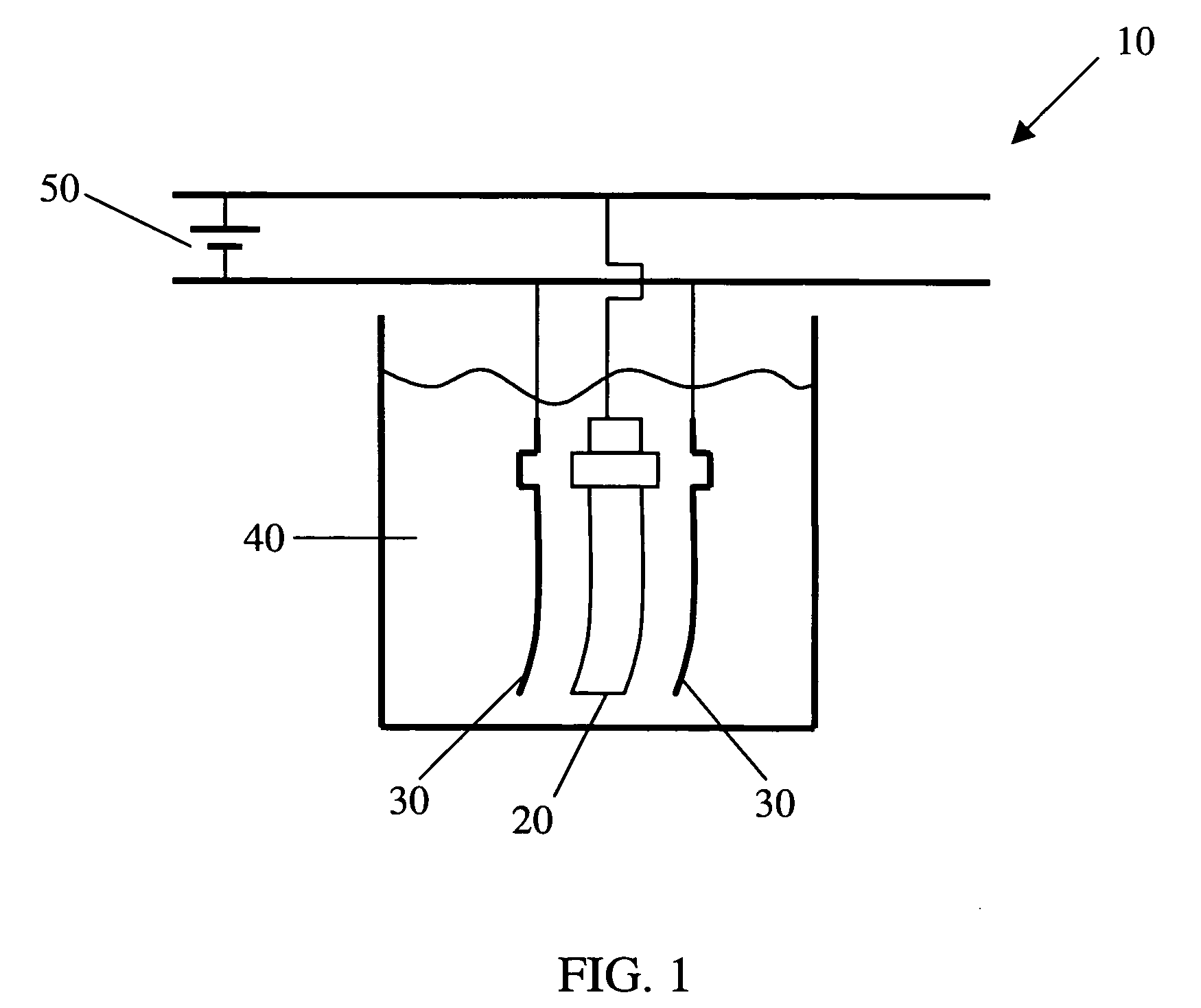

Image

Examples

examples 1-8

[0035] All of the substrates described below were electropolished in an electrolyte comprising about 95 wt % ethylene glycol, about 5 wt % potassium chloride, and a water content of less than 0.01 wt %. The temperature was 115° C. and the current density was 2 A / cm2 with a voltage was about 30-60V. The electropolishing time was two minutes. The cathodes were 6 centimeter by 6 centimeter by 0.158 centimeter stainless steel 304 plates. The surface roughness was measured with a profilometer.

[0036] For Example 1, the substrate was a titanium 6-4 coupon (titanium 64 is an alloy containing about 6 weight percent aluminum, about 4 weight percent vanadium, and the balance titanium). After electropolishing at a maximum metal removal rate of 0.00125 inches per minute, a smooth and shining surface was obtained. The surface roughnesses before and after electropolishing were 50 and 15 microinches, respectively.

[0037] For Example 2, the substrate was a titanium 6-4 engine blade. After electropo...

example 9

[0044] 65 milliliters (ml) spent electropolishing solution comprising ethylene glycol and potassium chloride in a 95:5 ratio by weight and 35 wt % titanium-containing solid was heated to an elevated temperature of 115° C. in a glass beaker. While at the elevated temperature, the spent electropolishing solution was sparged with compressed air for one hour. Following sparging, the metal-containing solid particles began to settle. After about 20 minutes it was observed that about 20 ml of clear electropolishing solution was formed in the beaker while about 45 ml of a sediment bed remained at the bottom of the beaker.

example 10

[0045] In order to demonstrate the effectiveness of recovered electropolishing solution, spent electropolishing solution containing about 35 wt % titanium-containing solid, ethylene glycol and potassium chloride (in a weight ratio of 95:5, respectively) was mixed with water. The spent electropolishing solution to water ratio was maintained at 10:90 by weight. After distillation, the recovered electropolishing solution was reused to electropolish titanium metal and no changes in the electropolishing behavior were observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com