Method and apparatus for storing a mop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

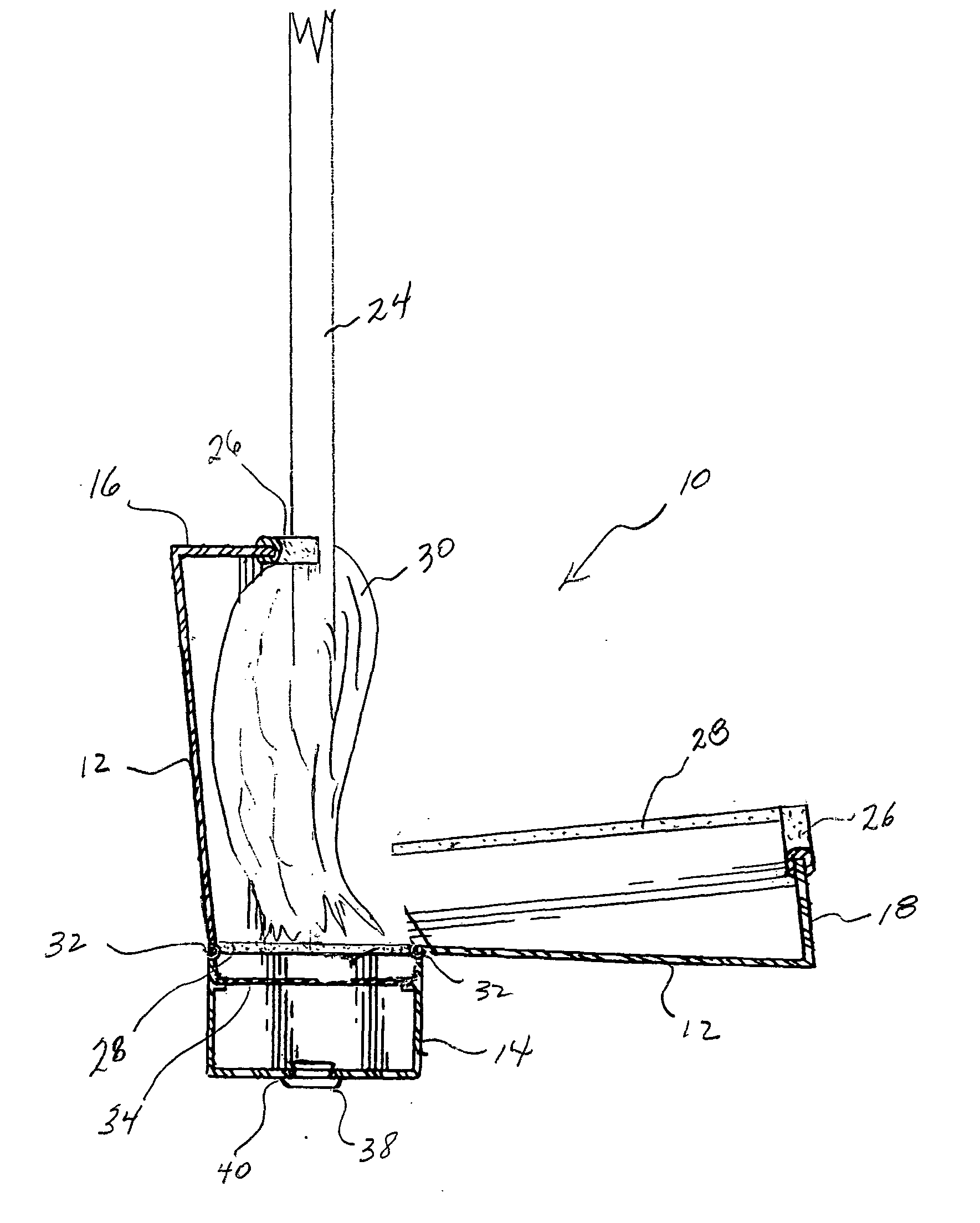

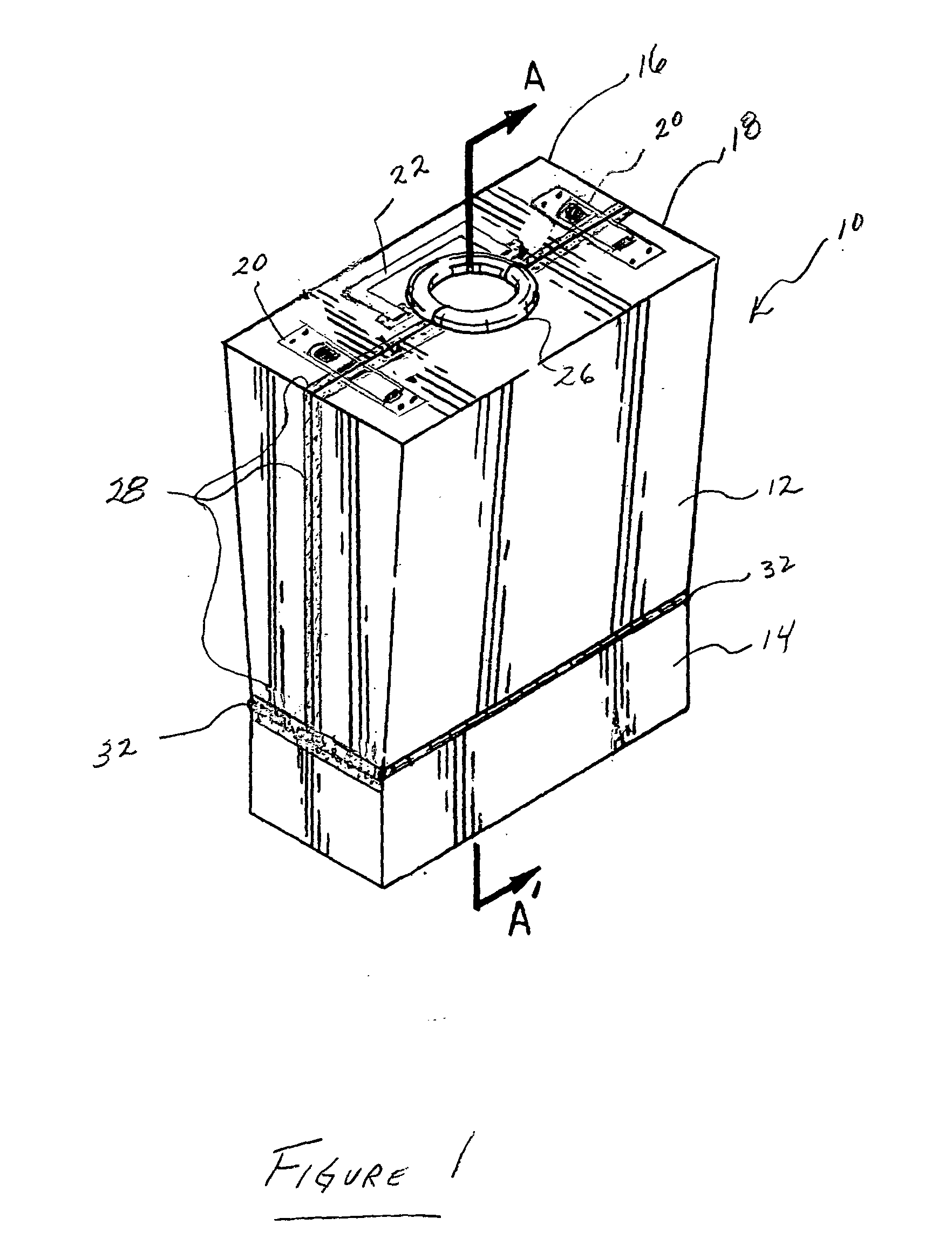

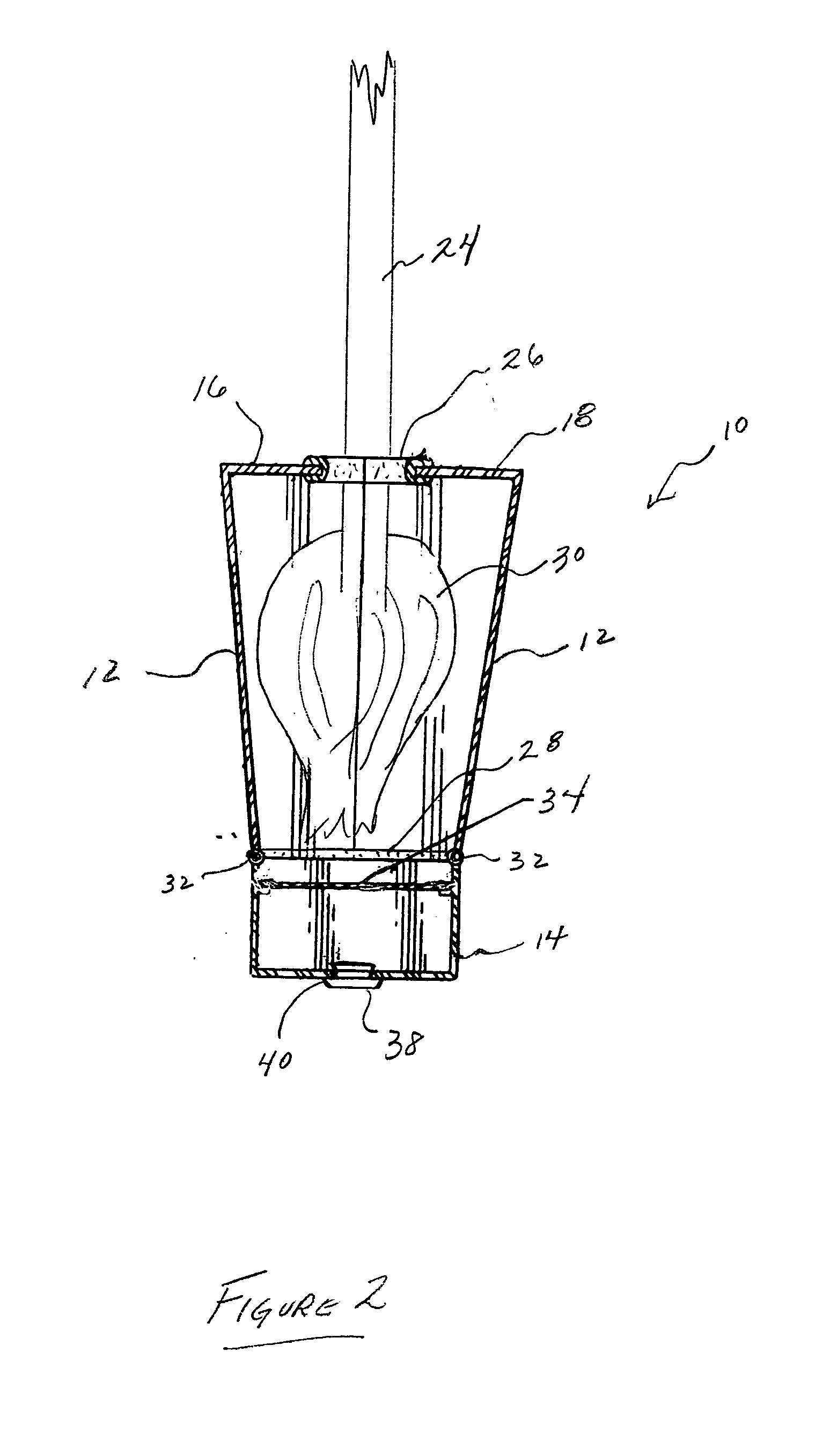

[0023]FIG. 1 shows a perspective view of a mop storage container 10 formed in accordance with the present invention. The mop storage container 10 preferably includes an upper housing 12 and a lower housing 14. The upper housing 12 is preferably adapted for storing a waxing or finishing mop. However, it is contemplated that the mop storage container 10 may be used to store a variety of maintenance implements while providing similar benefits. The lower housing 14 is preferably adapted for collecting and storing residual waxing and / or finishing material that has dripped from the mop stored in the upper housing 12.

[0024] The upper housing 12 preferably includes a first member 16 and a second member 18 that extend upperwardly from the lower housing 14. At least one of the first member 16 and the second member 18 is hinged to the lower housing 14. Alternatively, the upper housing 12 and lower housing 14 may be manufactured as a single unit having flexible first and second members 16, 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com