Expansion joint system

a technology of expansion joints and expansion joints, applied in the direction of resiliently mounted floors, bridge structural details, bridges, etc., can solve the problems of inability the sealing of exposed thin lateral wings or flaps is not designed to withstand heavy loads or other wear and tear, and the conventional methods of holding expansion joints in place are not always satisfactory, so as to facilitate the extrusion of continuous lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

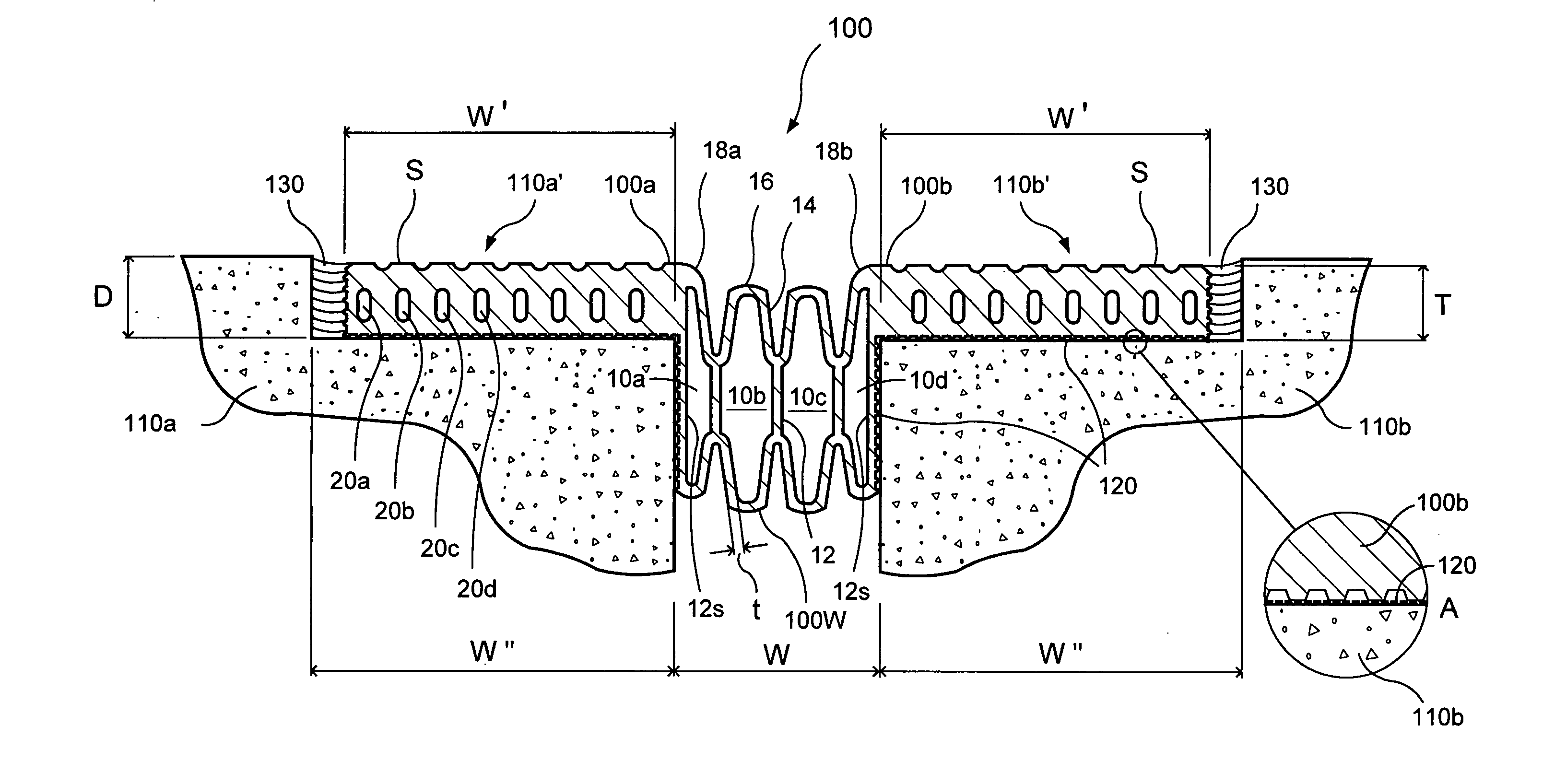

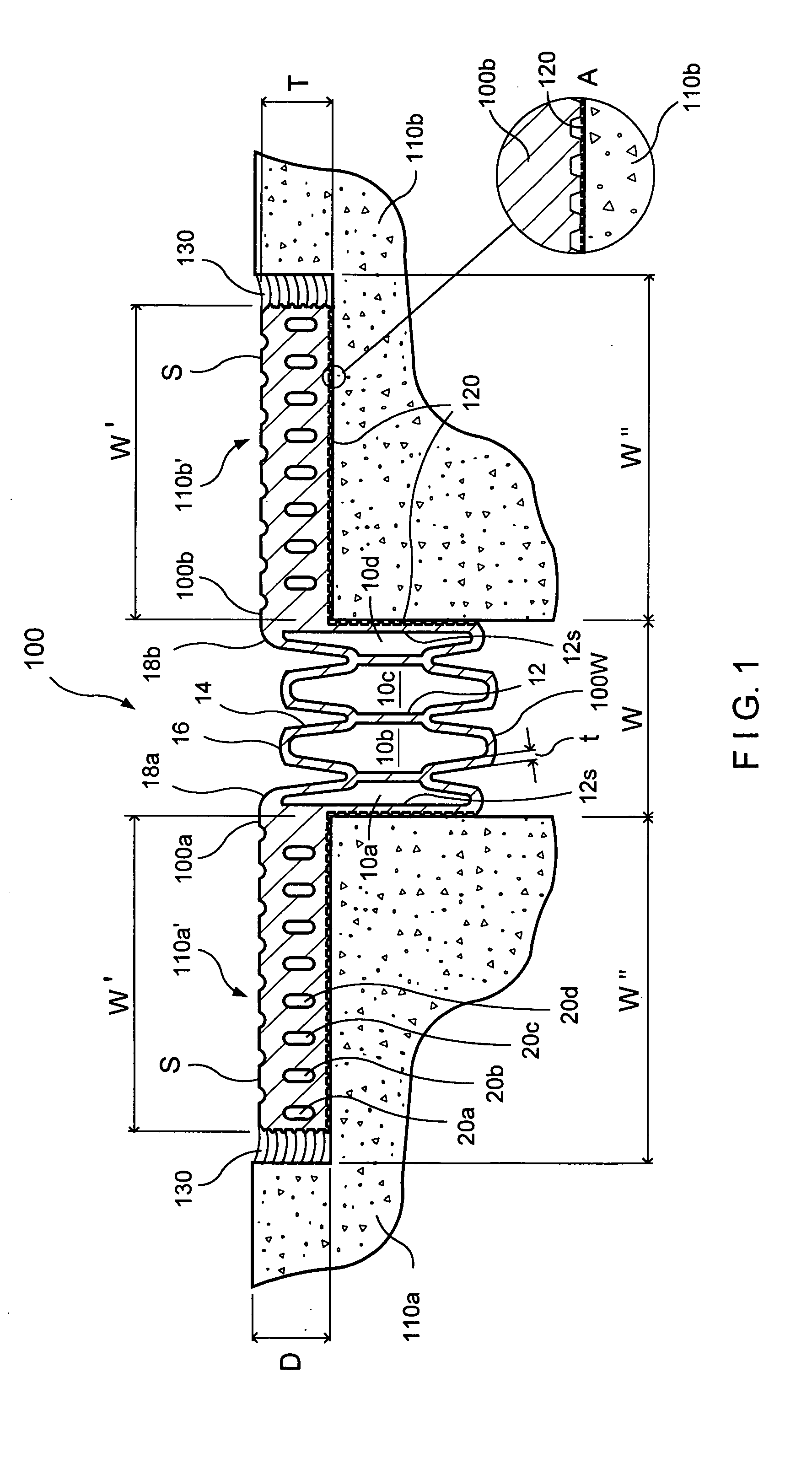

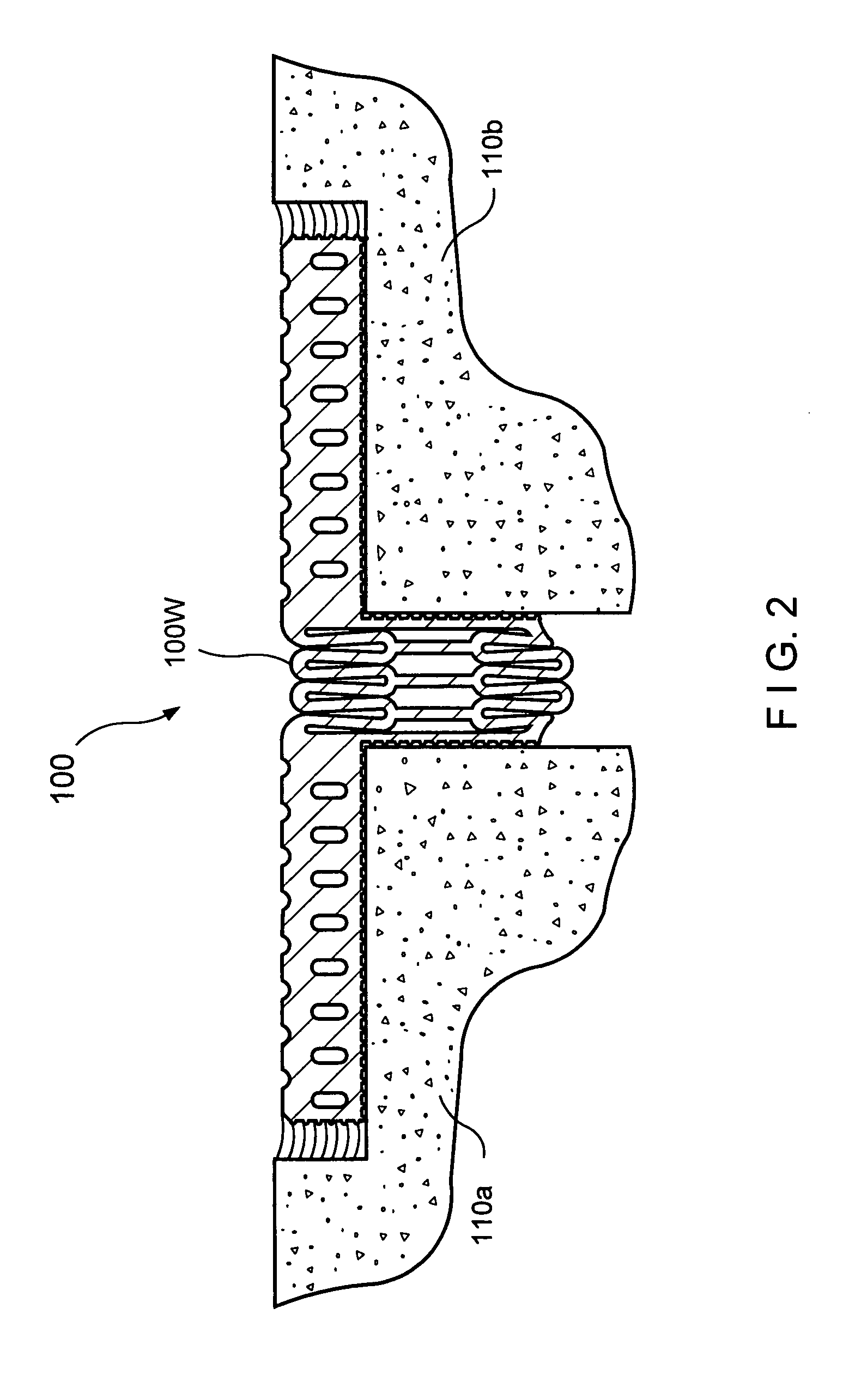

[0017] The inventive compression seals are designed for use in expansion joints between adjoining structural elements of various geometrical orientations or configurations. The expansion joints may, for example, be between coplanar concrete slabs, between stepped concrete slabs, or between a concrete slab and a wall. An exemplary compression seal 100 includes a dynamic compressible portion 100W supported between lateral load-bearing wings 100a and 100b (FIGS. 1-3).

[0018]FIGS. 1-3 show compression seal 100 installed in an expansion joint between a pair of adjoining concrete slabs 110a and 110b, which are substantially coplanar. The expansion joint has a width W between the edge walls of concrete slabs 110a and 110b. The pair of adjoining concrete slabs 110a and 110b may, for example, be precast concrete slabs of the type commonly used in concrete parking deck structures. In such use, expansion joint width W may, for example, have a nominal value of about 2 inches (FIG. 1). Longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com