Self aligning tray and carrier apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] While the present invention will be described herein with reference to particular embodiments thereof, a latitude of modifications, various changes and substitutions are intended, and it will be appreciated that in some instances some features of the invention will be employed without a corresponding use of other features without departing from the spirit and scope of the invention as described with respect to the preferred embodiments set forth herein.

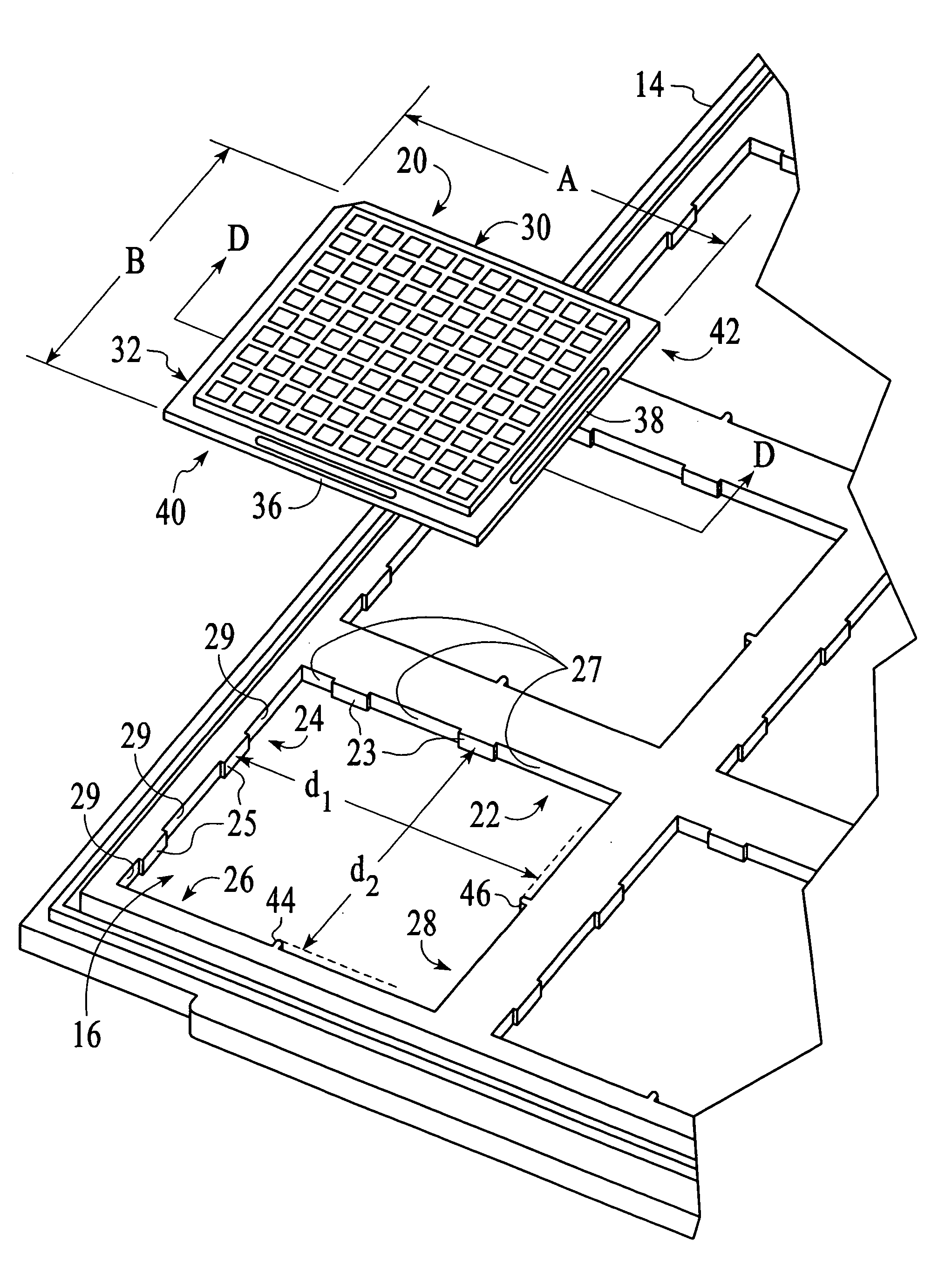

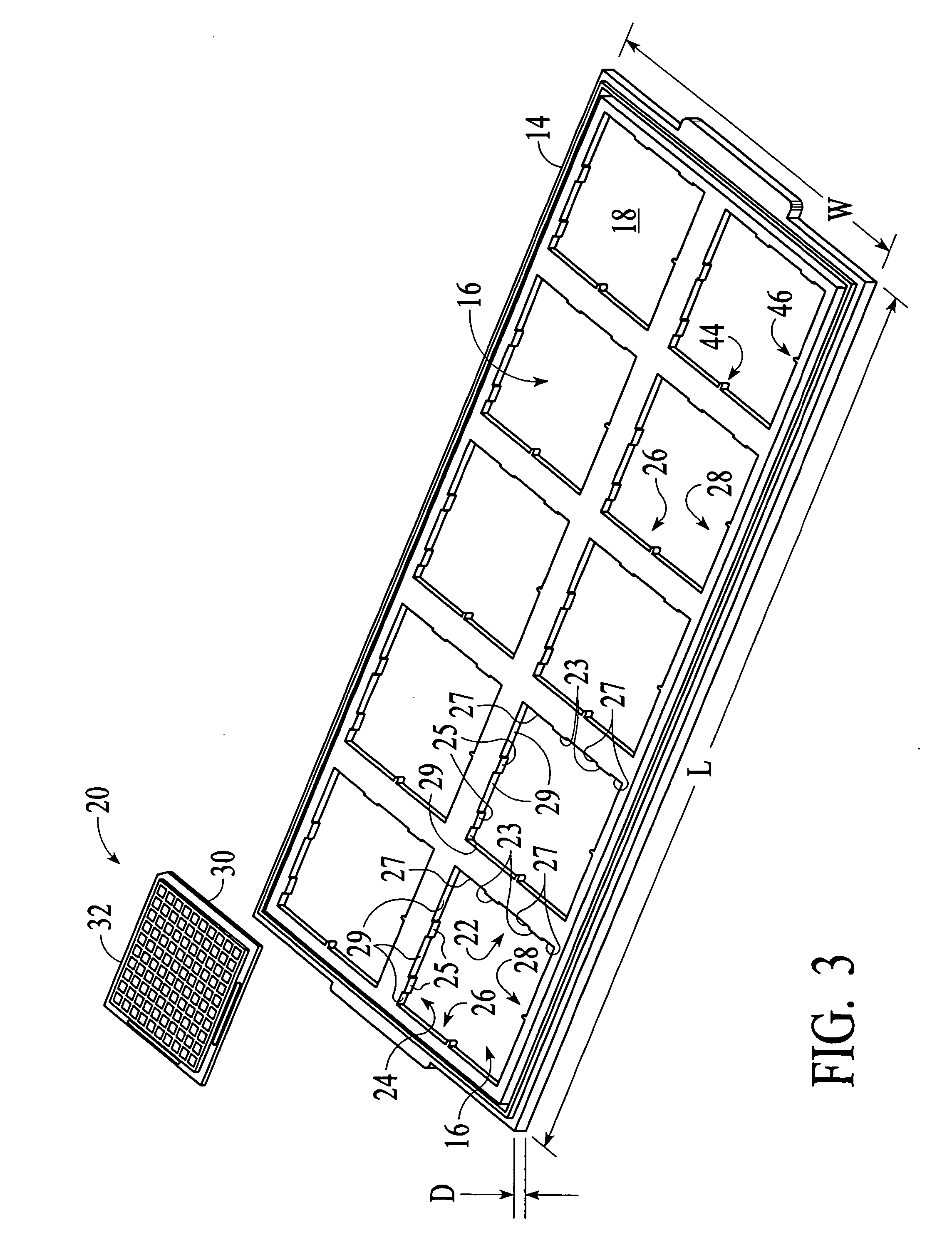

[0024] Referring now to FIG. 3, one embodiment of the present invention includes a carrier tray 14 having dimensions L, W and D, any one or more of which may in an alternate embodiment conform to a JEDEC standard. Within the dimensions L, W and D, the carrier tray 14 includes a plurality of carrier tray pockets 16. Although ten pockets 16 are shown in FIG. 3, the present invention includes any quantity. Each pocket 16 has a bottom structure 18 providing vertical support upon which a component tray, illustrated by tray 20, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com