Frequency compensated oscillator design for process tolerances

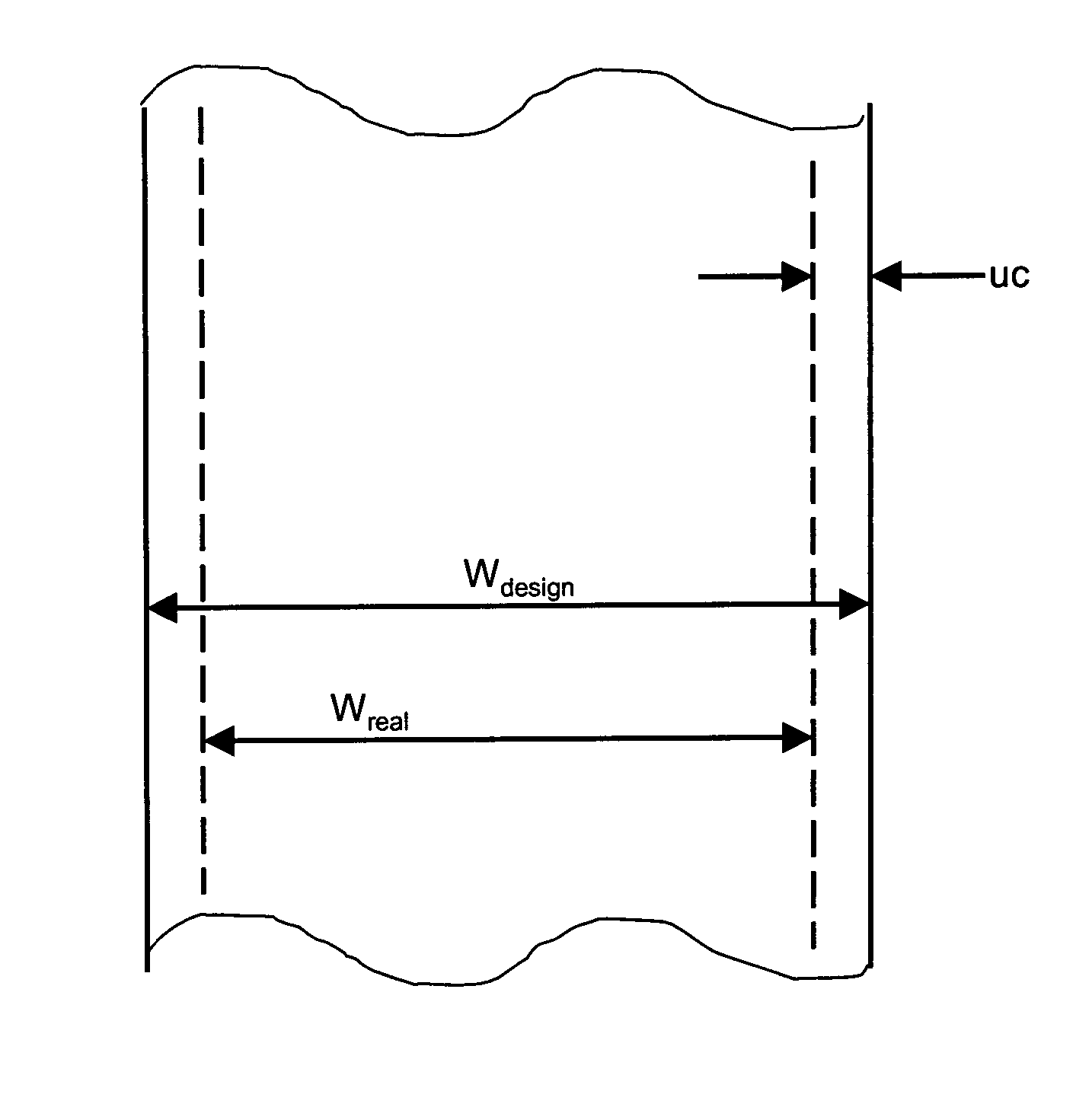

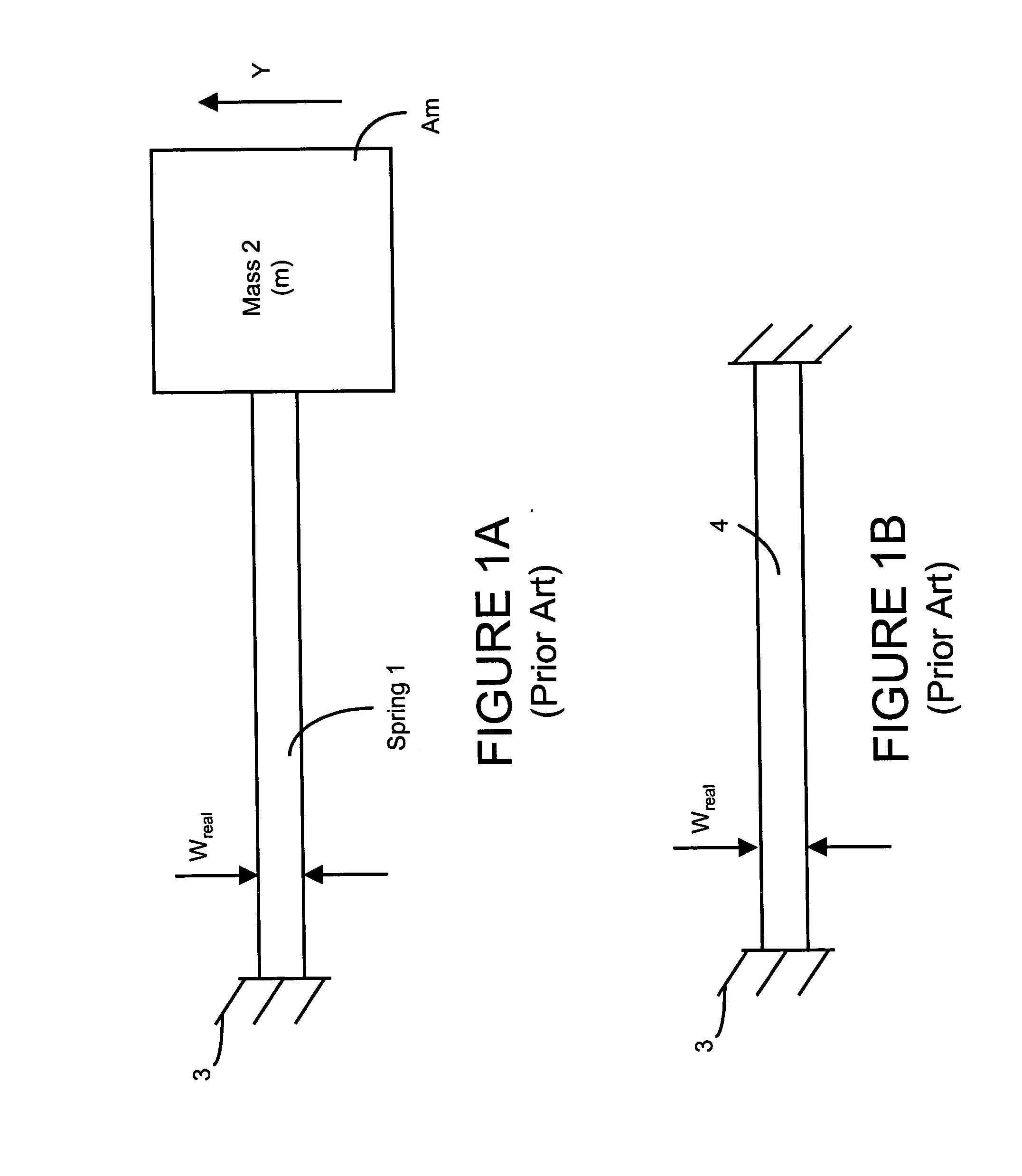

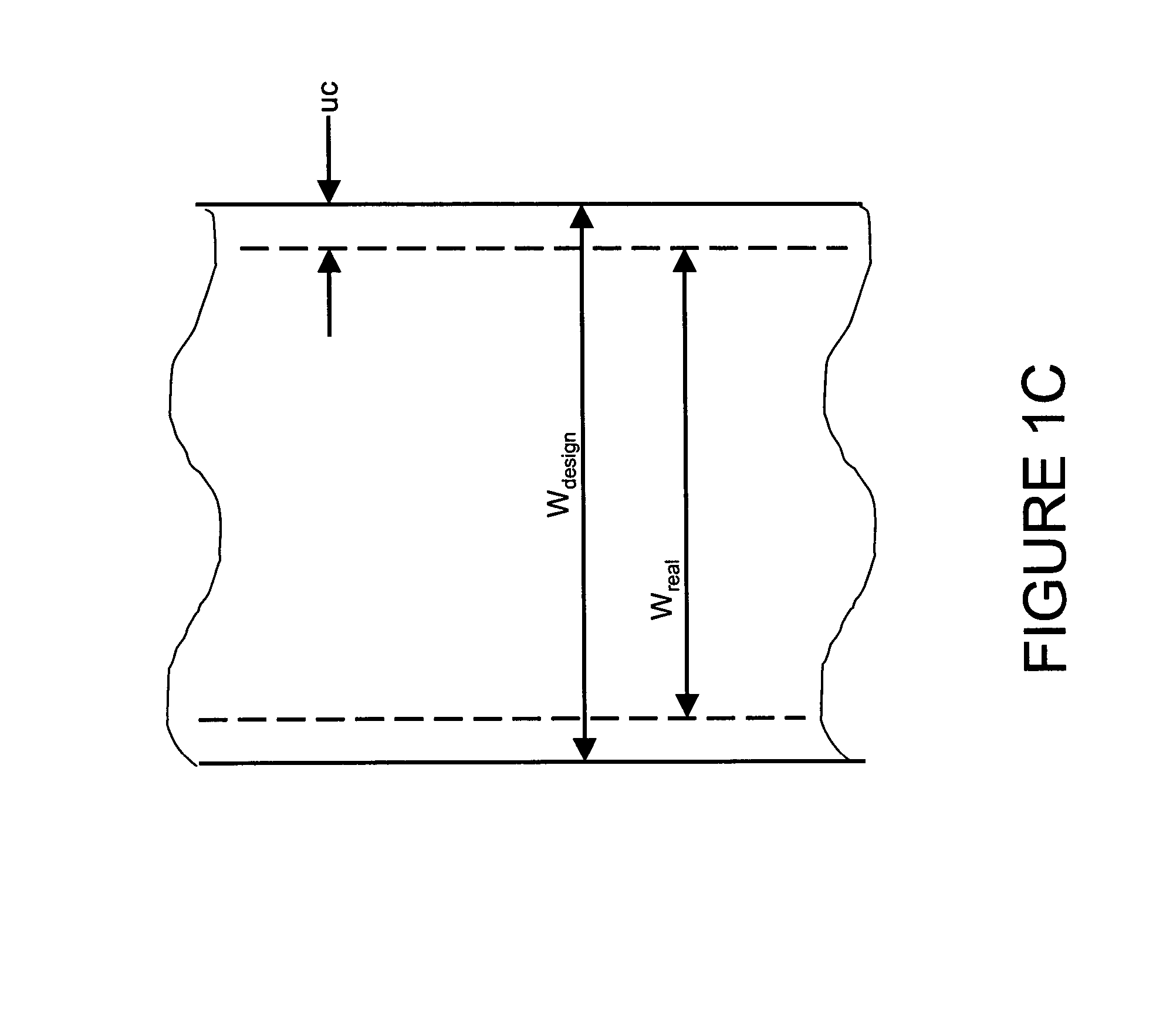

a frequency compensated oscillator and process tolerance technology, applied in special foundation layouts, machine frames, stands/trestles, etc., can solve the problems of inacceptable significant variations in spring width, adversely affecting performance, and spring mechanism actual widths that differ, so as to increase immunity and increase manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A number of teaching embodiments are presented below which describe to making and use of the present invention. The embodiments are selected examples. The full scope of the present invention is, however, defined by the claims that follow. Examples of discrete, continuous, and hybrid resonators are presented below. Those of ordinary skill in the art will recognize that the distinction between broad resonator classes is done for purposes of clarity. The present invention is readily applicable to at least the entire range of resonator structures adapted for use in MEMS.

The term “beam” or “beam / mass structure” is used to broadly denote a class of mechanical elements commonly used in MEMS to define a frequency of interest. Beams take many specific forms and may be used, for example, in the suspension of rigid plates, as lateral oscillators, or as cantilever devices. Beam structures are a natural choice for bearing-less motion detectors. Of particular note, MEMS increasingly use beams wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| frequencies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com