System and method for current sensing using Anti-differential, error correcting current sensing

a current sensing and error correction technology, applied in the field of current measurement and monitoring, can solve the problems of many inherent limitations, inapplicability of dc applications, and inability of shunt-type sensors to adapt to alternating current applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

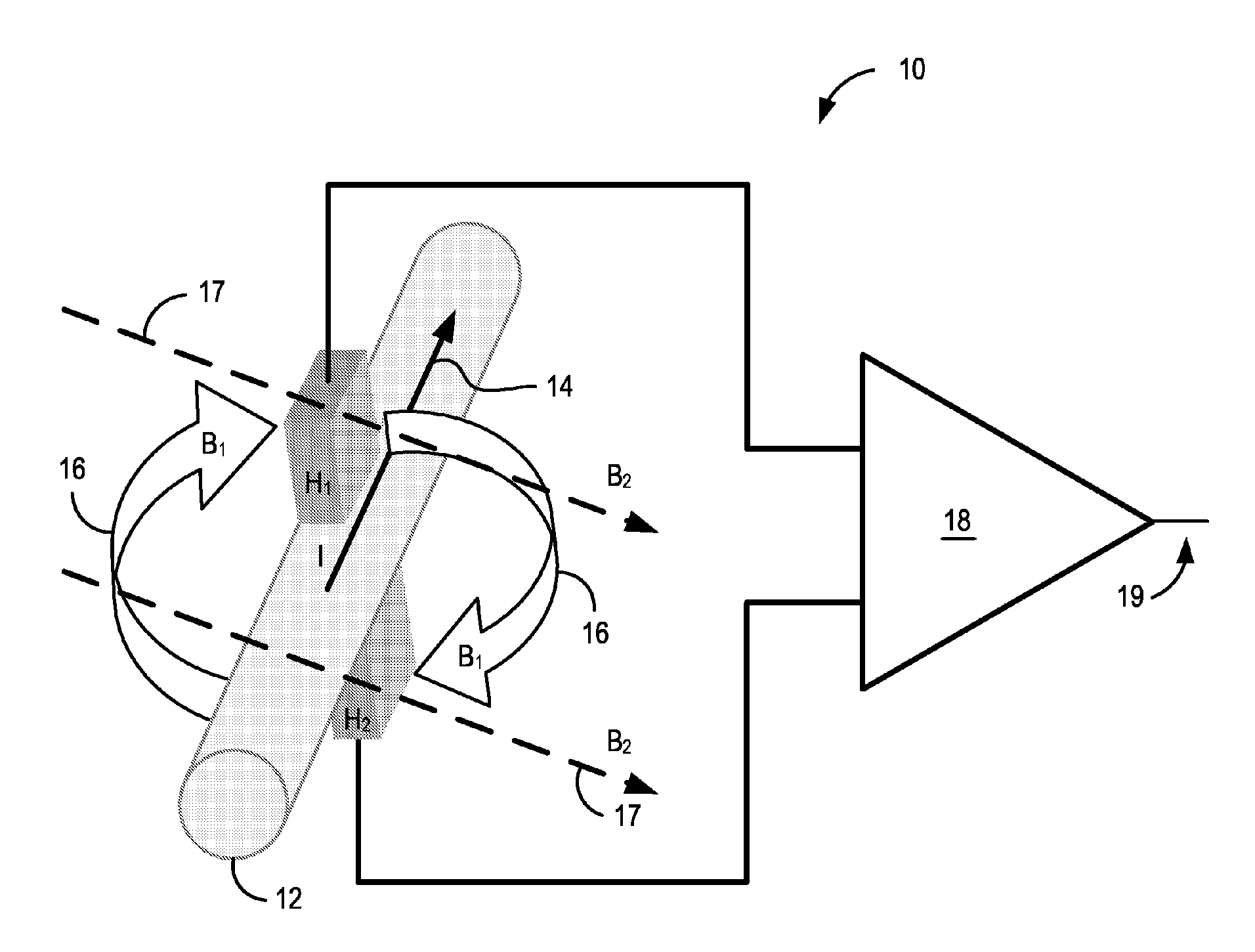

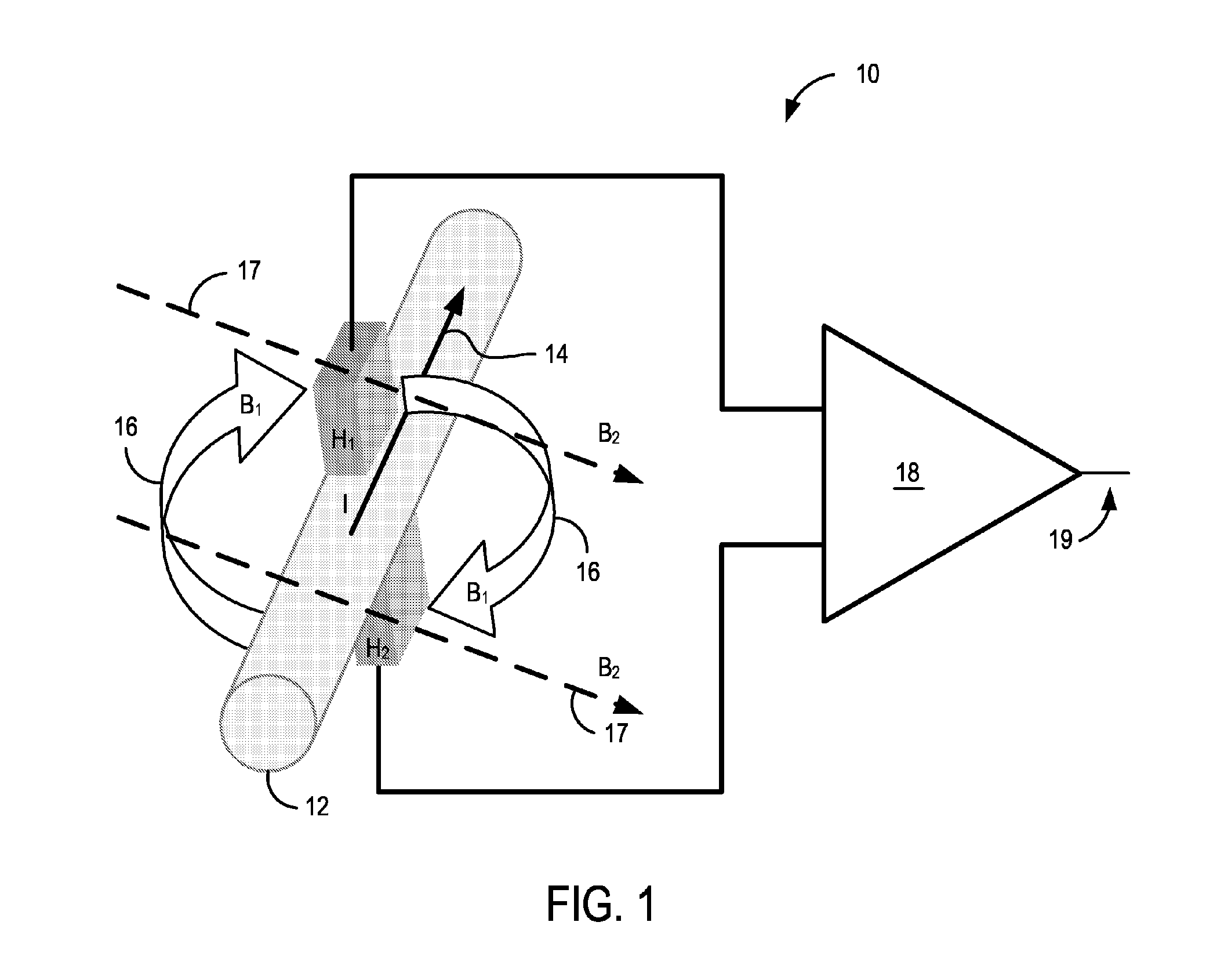

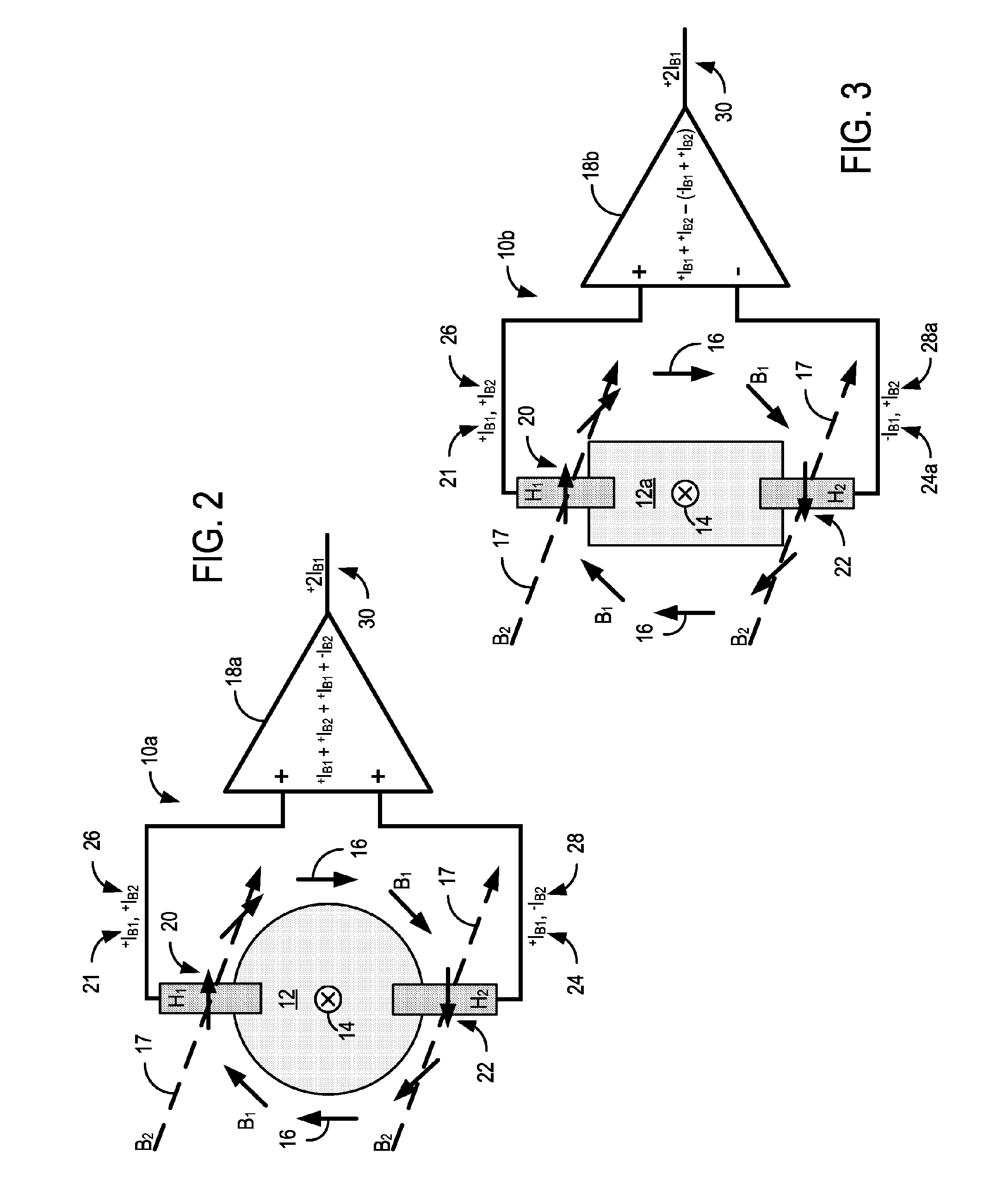

[0030] The present invention is related to a system and method for non-contact based, anti-differential, error-correcting current sensing. A plurality of magnetic flux sensors is arranged about a conductor and provides feedback to a processing component or device configured to generate an output with reduced feedback induced by magnetic fields external to the conductor. The plurality of magnetic flux sensors may be disposed in geometrically designed recesses configured to amplify the magnetic flux received by the plurality of magnetic flux sensors. The system may be disposed in a variety of configurations designed for optimal disposition of the plurality of magnetic flux sensors about a given conductor type. Some examples of possible configurations include etched spiral path topologies for low current and printed circuit board current sensing, dual-spiral and spiral-helix topologies for contact based current sensing, and wire and bus bar mount topologies for wire and bus bar conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com