Immediate post-extraction implant

a post-extraction and implant technology, applied in the field of dental implants, can solve the problems of large conical cavity, inability to self-tuck implants, and inability to achieve self-tucking implants, and achieve the effect of promoting adhesion between the implant and the surrounding bone and putting in service in a reasonably short period of tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The design requirements for dental implants placed into immediate extraction sites differ significantly from the design of general implants used presently for placement in edentulous jawbones. Today all implants used in immediate extraction sites are either threaded, coated with a surface material or sintered. However, these implants do not provide the best design for immediate fresh extraction sites. Such immediate extraction sites require an implant designed specifically to address the morphology of the bony defect created during the extraction of a tooth.

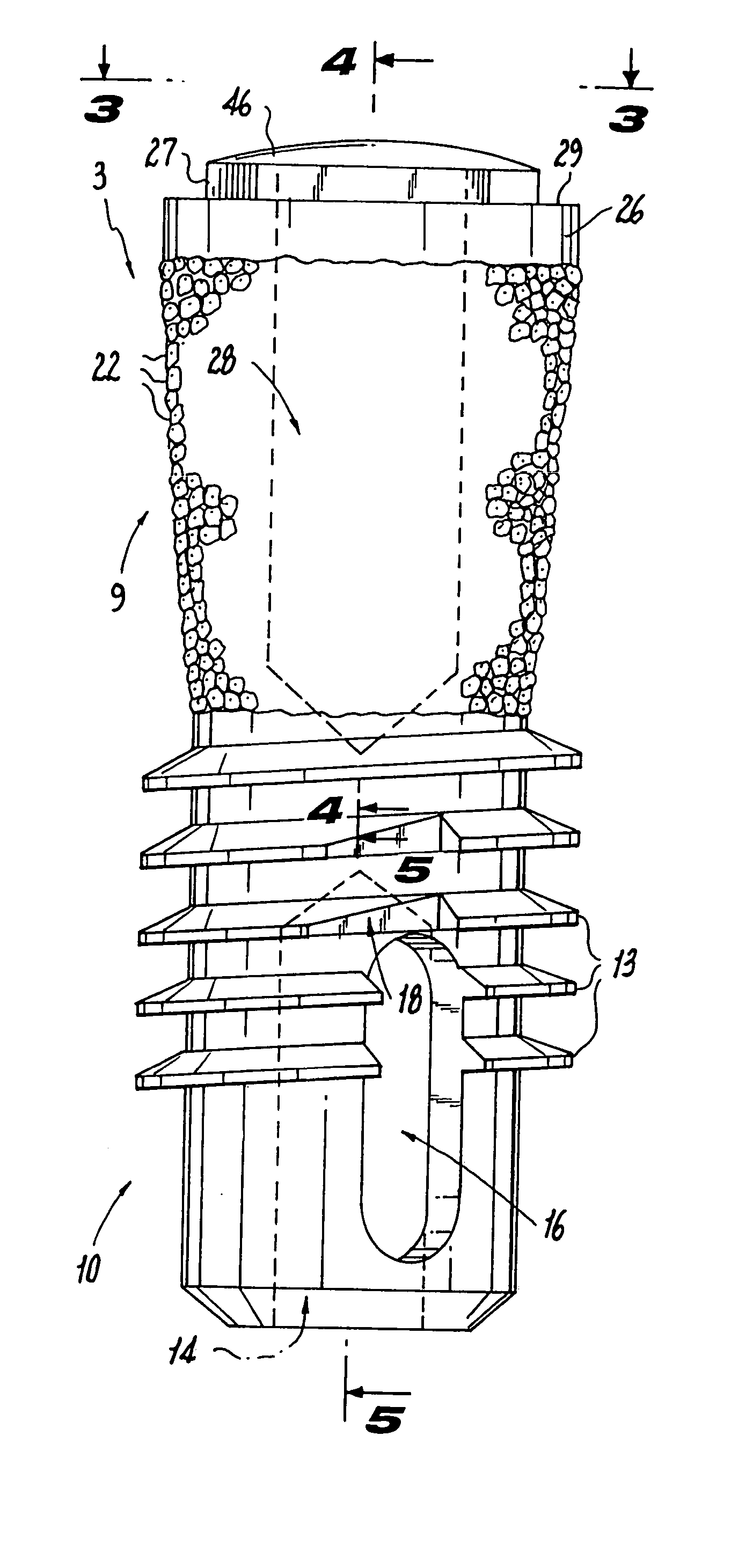

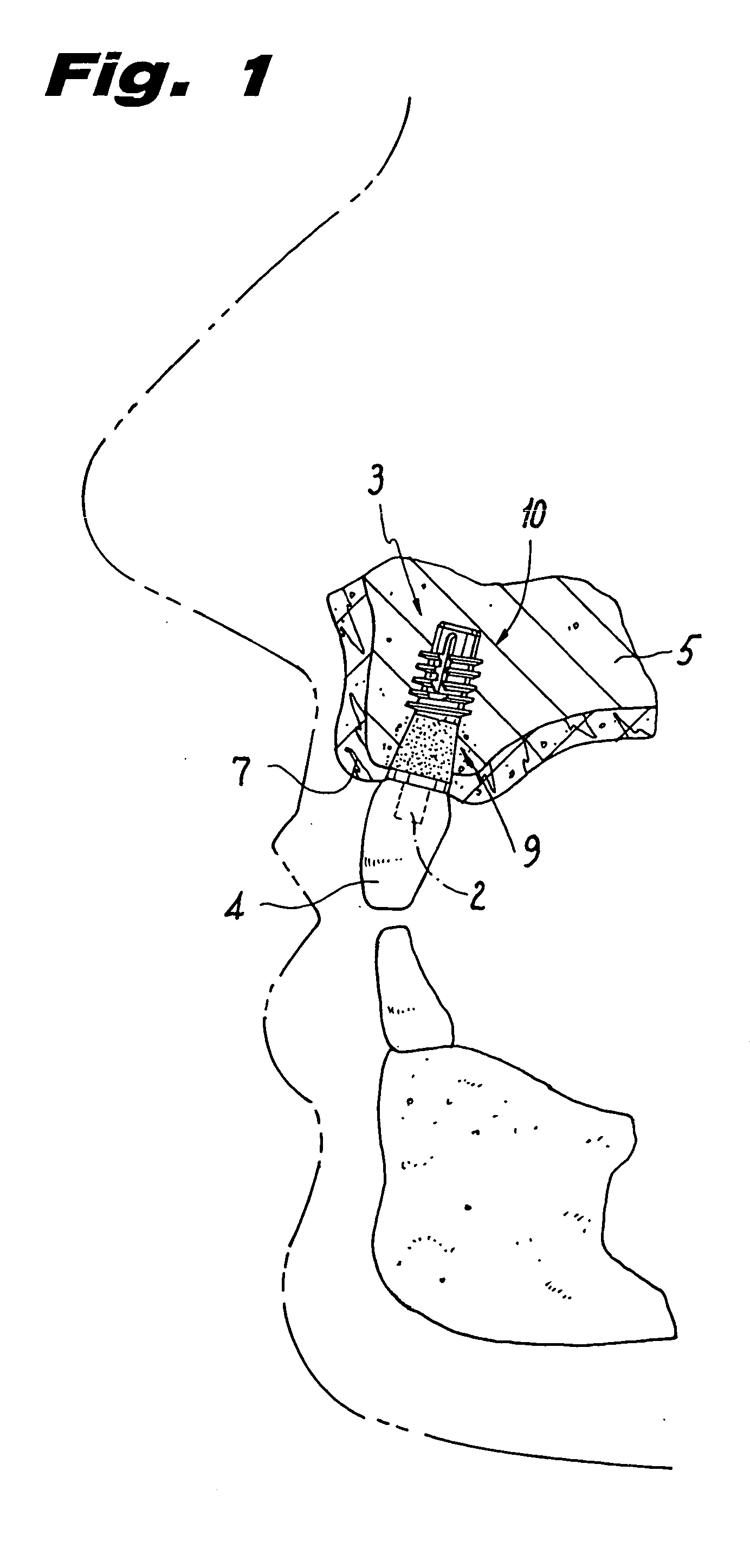

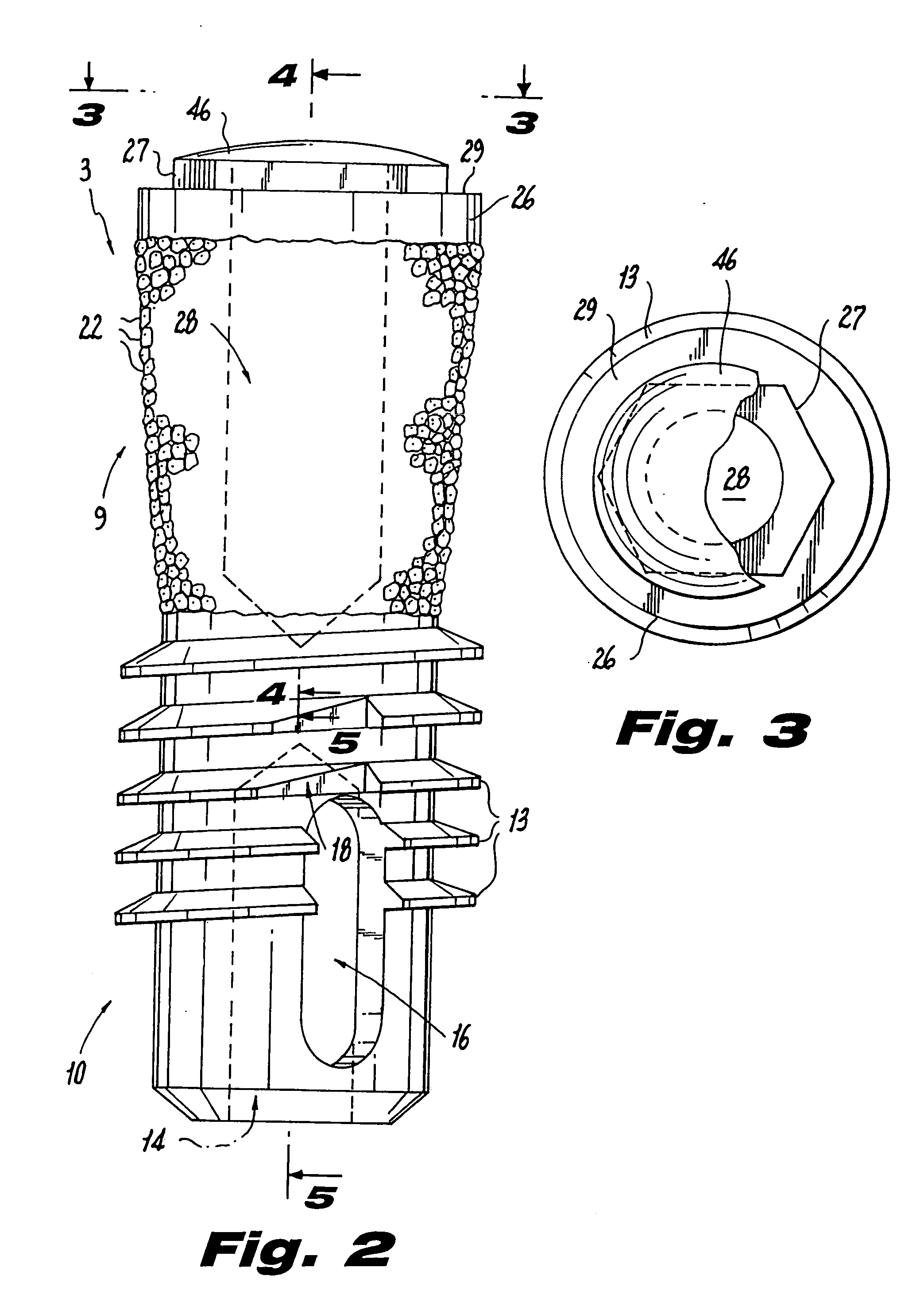

[0026] The implant system of the present invention is at least a two part screw-type dental implant 3 (FIG. 1), having a threaded cylindrical lower portion 10 that is buried in the bone 5 of the patient and an upper portion 9, preferably generally conically-shaped, that is attached thereto. The upper portion 9 is covered by soft tissue 7. A post or abutment 2 is shown in dotted line extending from upper portion 9 and supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com