Method for producing line pipe

a production method and technology of steel line, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low low maximum hardness of pipe, and approaching yield to tensile ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] ) According to the present invention a method for the manufacture of steel line pipe includes providing a steel pipe having a composition consisting essentially of in weight percent: C 0.01 to 0.40, Mn 0.25 to 2.0, P residual to less than 0.5, S residual to less than 0.020, Si residual to 2.0, Cu residual to 1.0, Ni residual to 1.0, Cr residual to 2.0, Mo residual to 1.0, Al 0.010 minimum to less than 1.0, N residual to 0.030, V residual to less than 0.5, B residual to less than 0.02, Ti residual to less than 0.3, and Nb residual to less than 0.3, balance iron and incidental impurities. The pipe may be made by a seamless process or various other pipe manufacturing processes. The process for manufacturing the pipe is not in and of itself critical. Also, the pipe may have been subjected to various prior heat treatments.

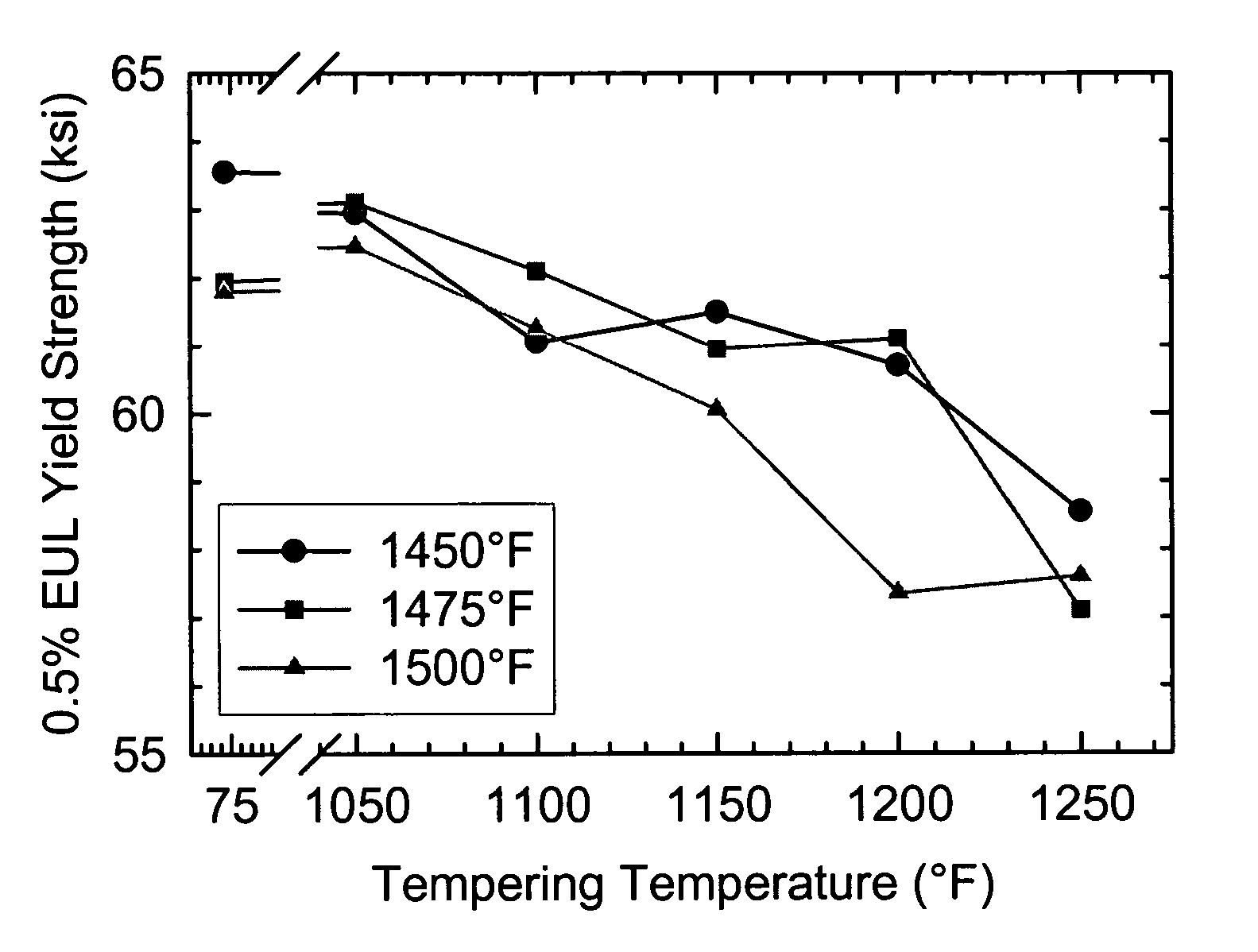

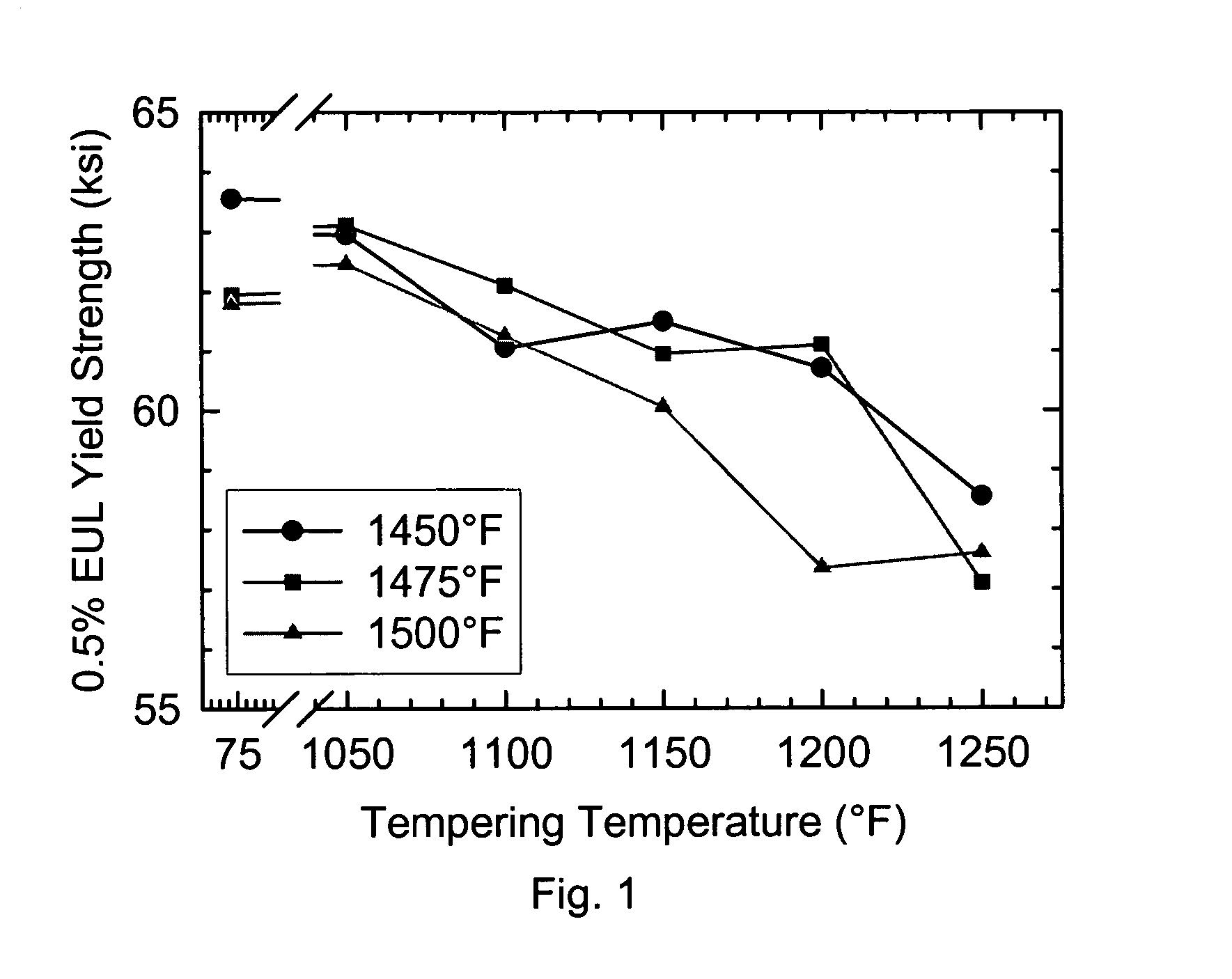

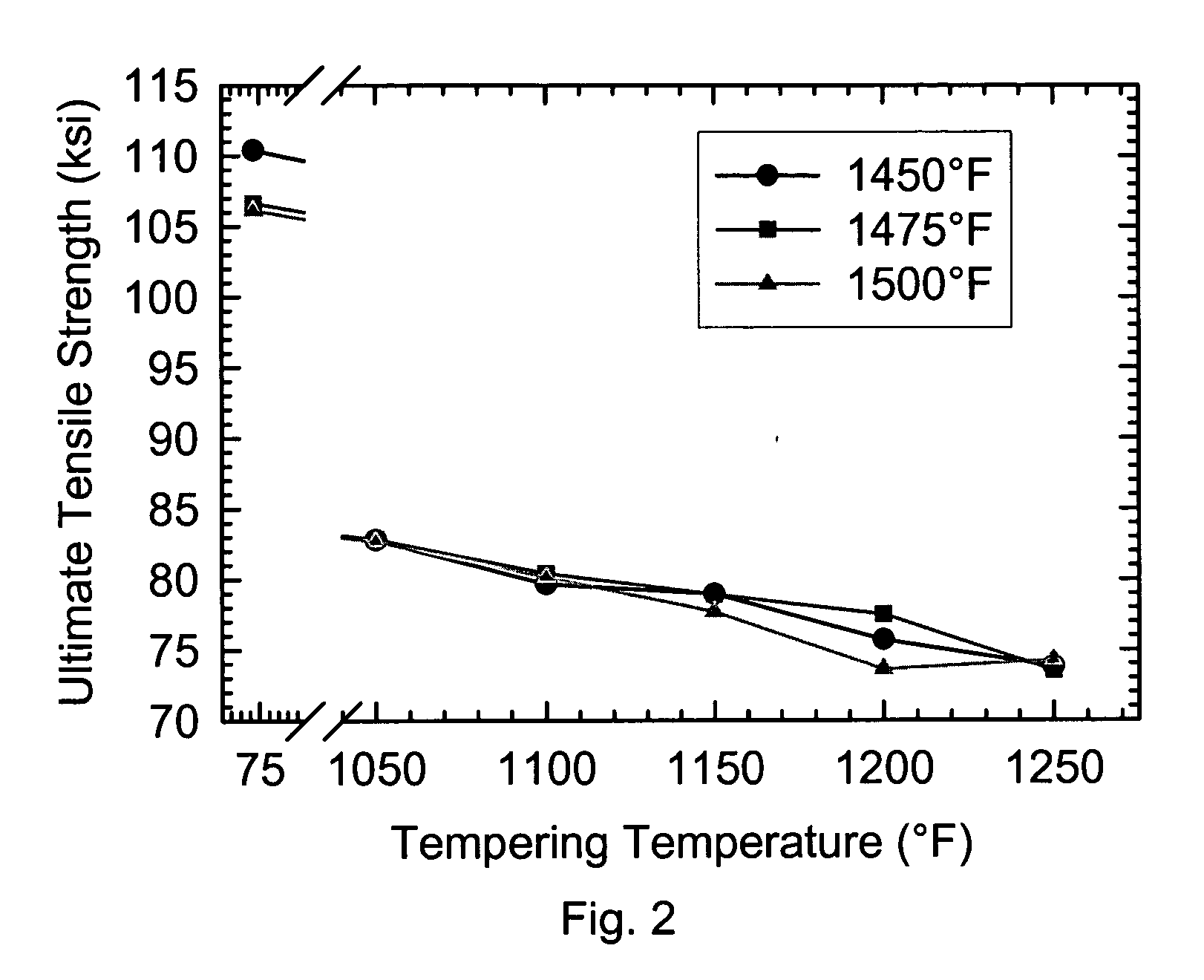

[0016] The pipe is heated to a temperature within the intercritical Ac1 to Ac3 temperature range to obtain ferrite and austenite in the microstructure. Preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com