Refrigeration system with a plate-type condenser and method for compacting it

a refrigeration system and condenser technology, applied in refrigeration machines, domestic cooling devices, lighting and heating devices, etc., can solve the problems of increasing the transportation cost of the refrigeration system from one place, the system is more difficult to move, etc., to achieve the effect of reducing the position of the evaporator coil, facilitating and facilitating both the handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

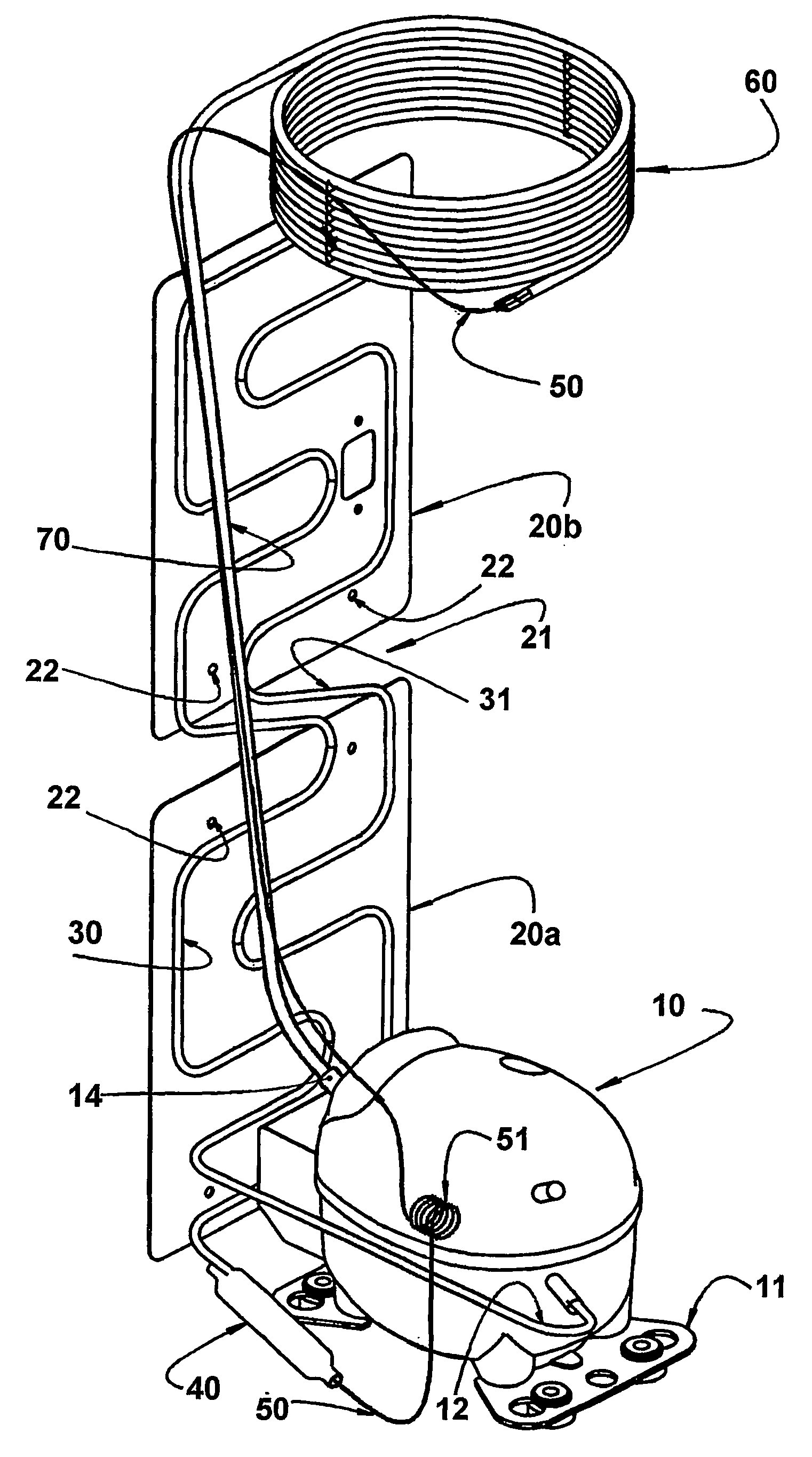

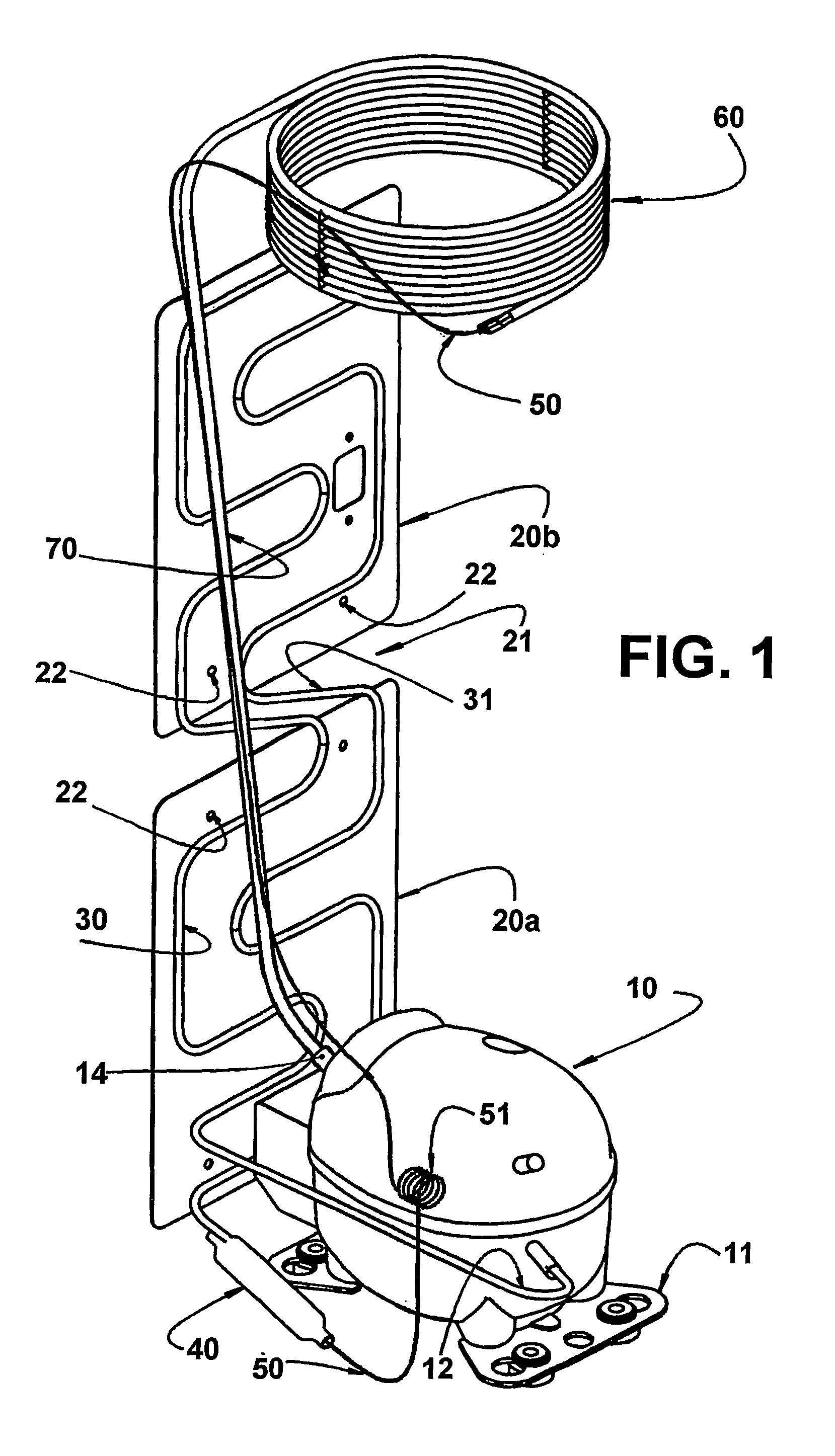

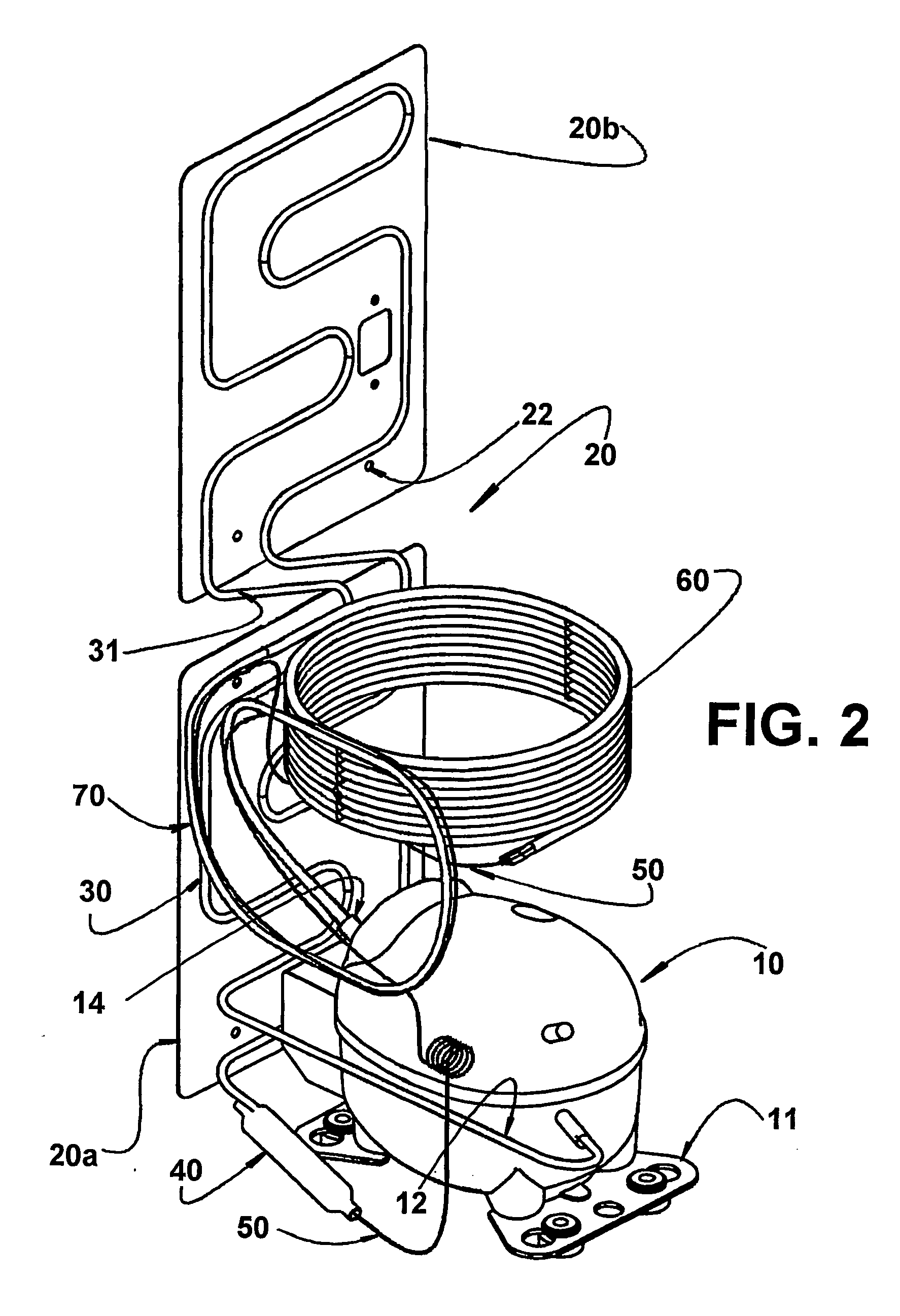

[0017]FIG. 1 shows a refrigeration system having the usual conventional components, but with a plate-type condenser constructed according to the invention. The refrigeration system is shown with a general arrangement of its components being positioned in the form they are designed to be mounted in the cabinet of a refrigeration appliance (not illustrated), and which also represents the final form after the manufacturing steps and test procedures. When mounted in the cabinet of the refrigeration appliance, the several components are supported by the adequate structural mounting members.

[0018] The system presents, at the bottom thereof, a compressor with a conventional construction mounted in a hermetic shell 10, which presents a mounting support 11, through which the hermetic shell 10 is mounted in the cabinet of the refrigeration appliance. The compressor compresses a high-pressure refrigerant fluid, which is supplied to a discharge tube 12 mounted to the hermetic shell 10 and whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com