Fire barrier system for building panels

a technology for building panels and expansion joints, applied in fireproofing, roofing, building components, etc., can solve the problems of reducing the installation time and cost of the invention, and affecting the installation effect of the invention, so as to save the installation time and cost. , the effect of saving the invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

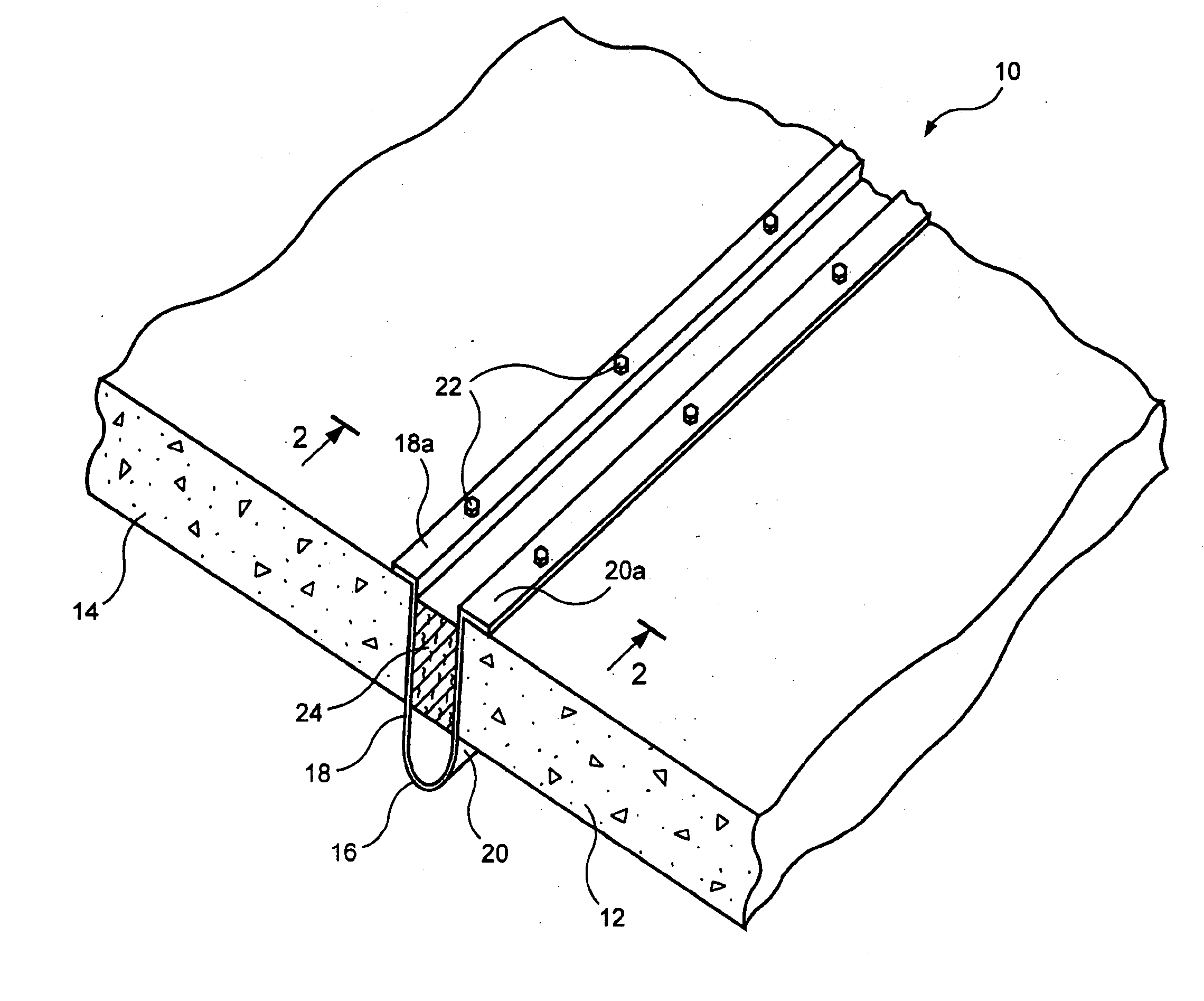

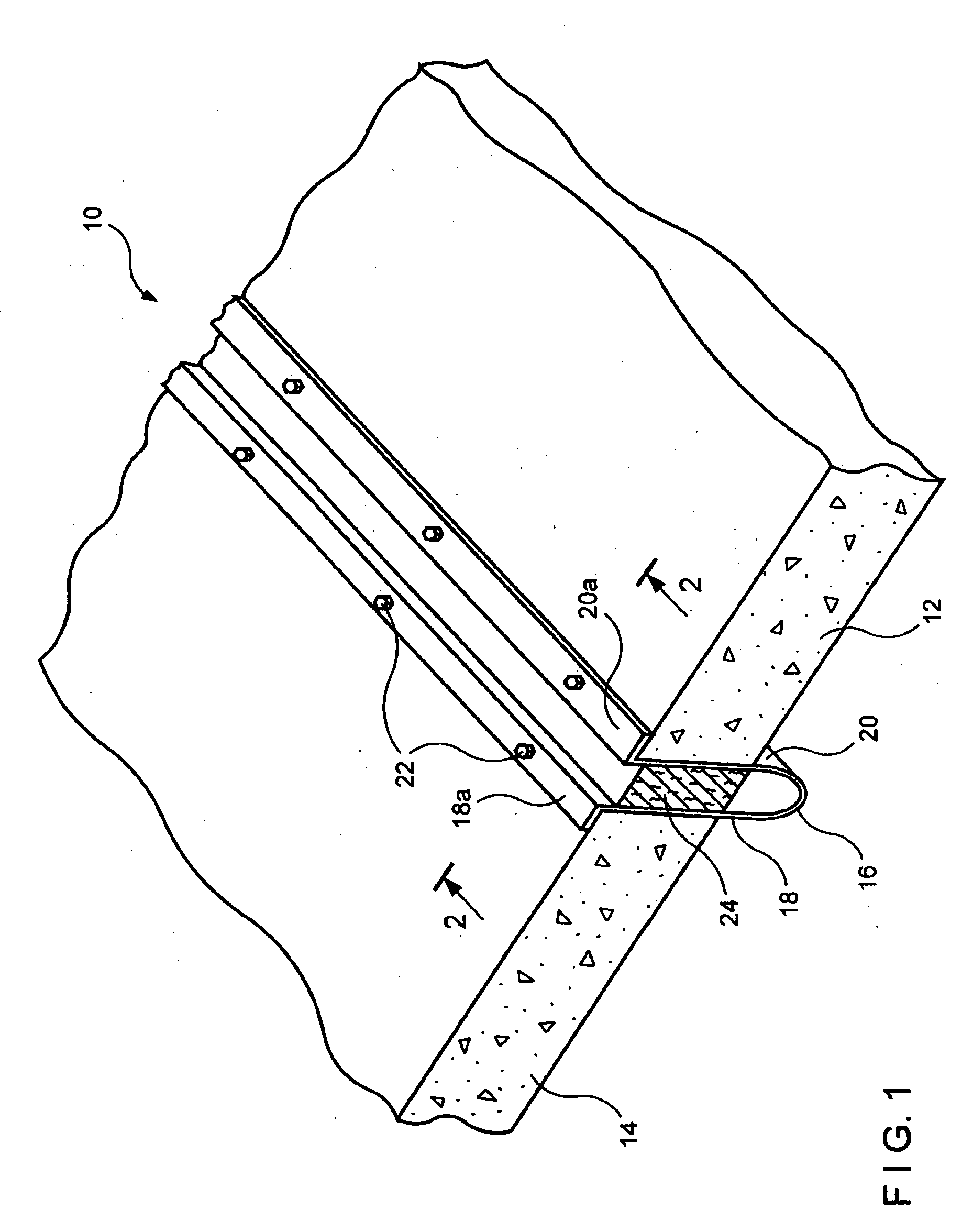

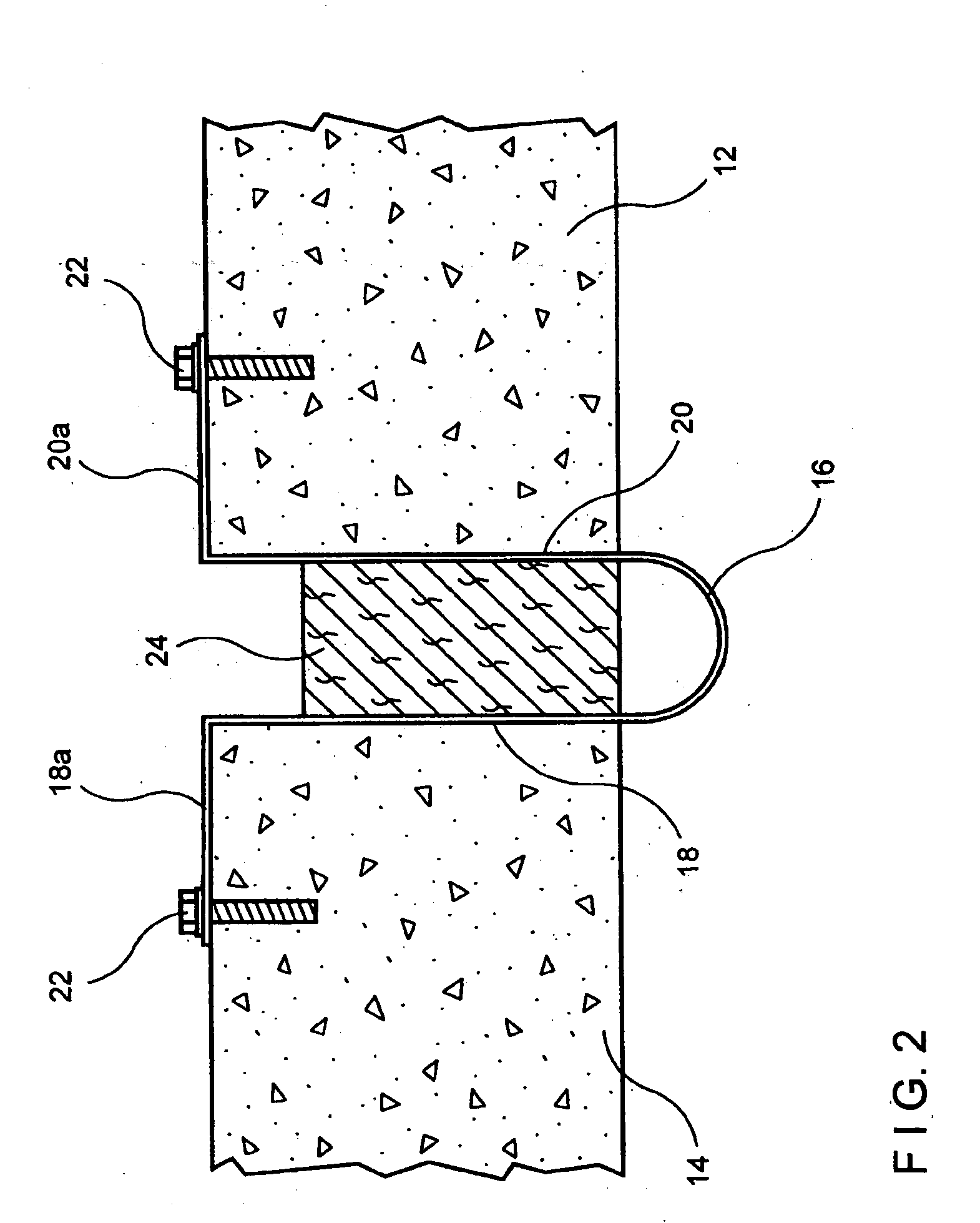

[0013] Referring now to the drawings, FIGS. 1 and 2 illustrate the novel expansion joint of the invention as installed between adjacent building panels of a structure. In this example, the building panels are shown as adjacent horizontal concrete slabs 12, 14 forming part of a floor of a structure, but it will be understood that the invention is applicable to adjacent vertical wall panels as well.

[0014] The joint structure 10 comprises a heat shield or drape 16 made of 2 mil (0.002 inch) thick impermeable stainless steel foil, formed into a longitudinally extending generally U-shaped trough, the opposite legs of which are indicated at 18 and 20. The legs 18, 20 are bent along their longitudinal edges at 90° to form flanges 18a and 20a. The drape 16 can be either metallic or woven ceramic. The drape 16 can also be woven from fire retardant fabric and should be flexible. When installed between slabs 12 and 14, the flanges overlay the upper surfaces of the adjacent slabs and bolts or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com