Corrosion resistant prestressed concrete float system

a prestressed concrete and float system technology, applied in the direction of groynes, special-purpose vessels, vessel construction, etc., can solve the problems of corroding wire reinforcement mesh and weakening the strength of the dock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

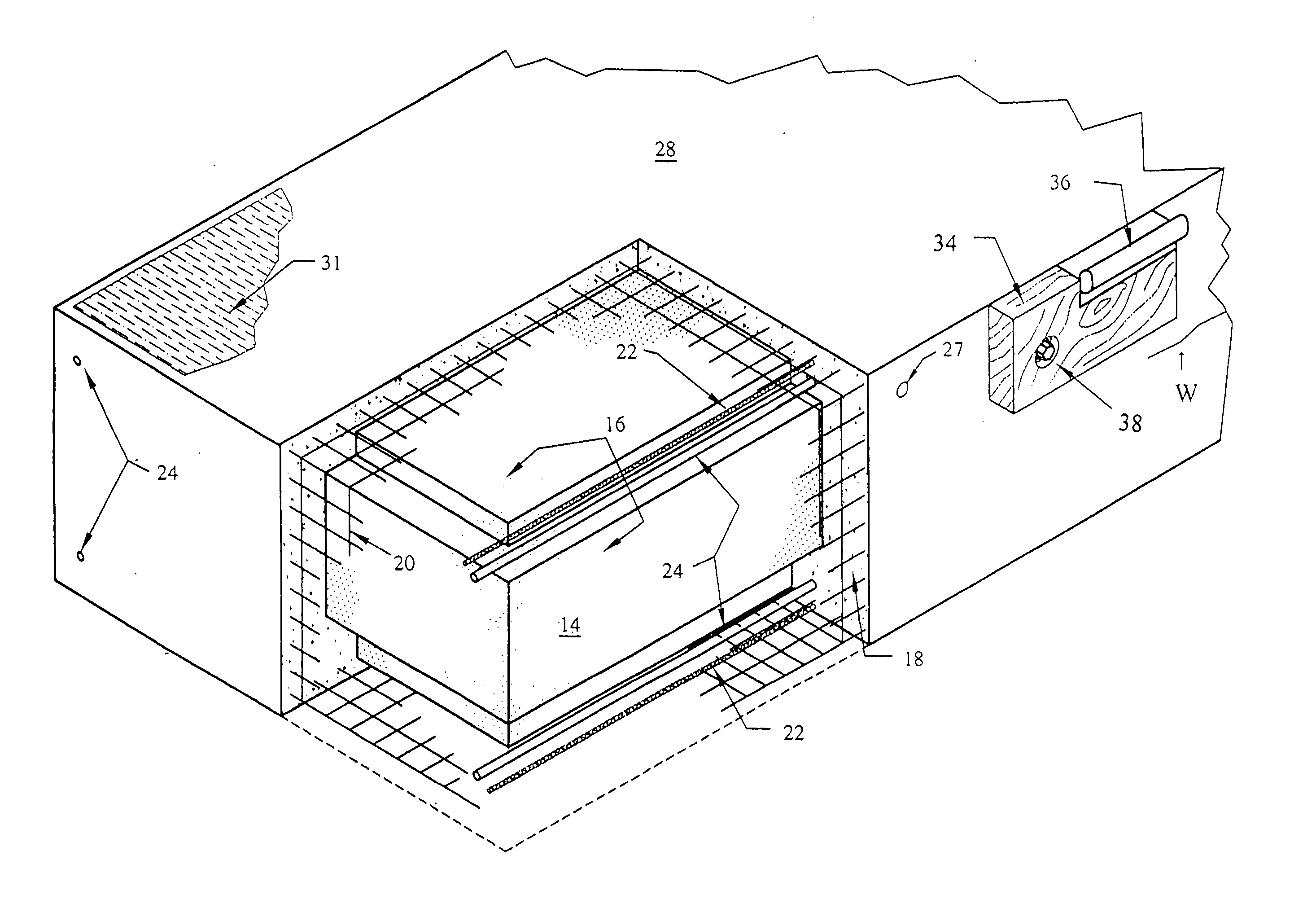

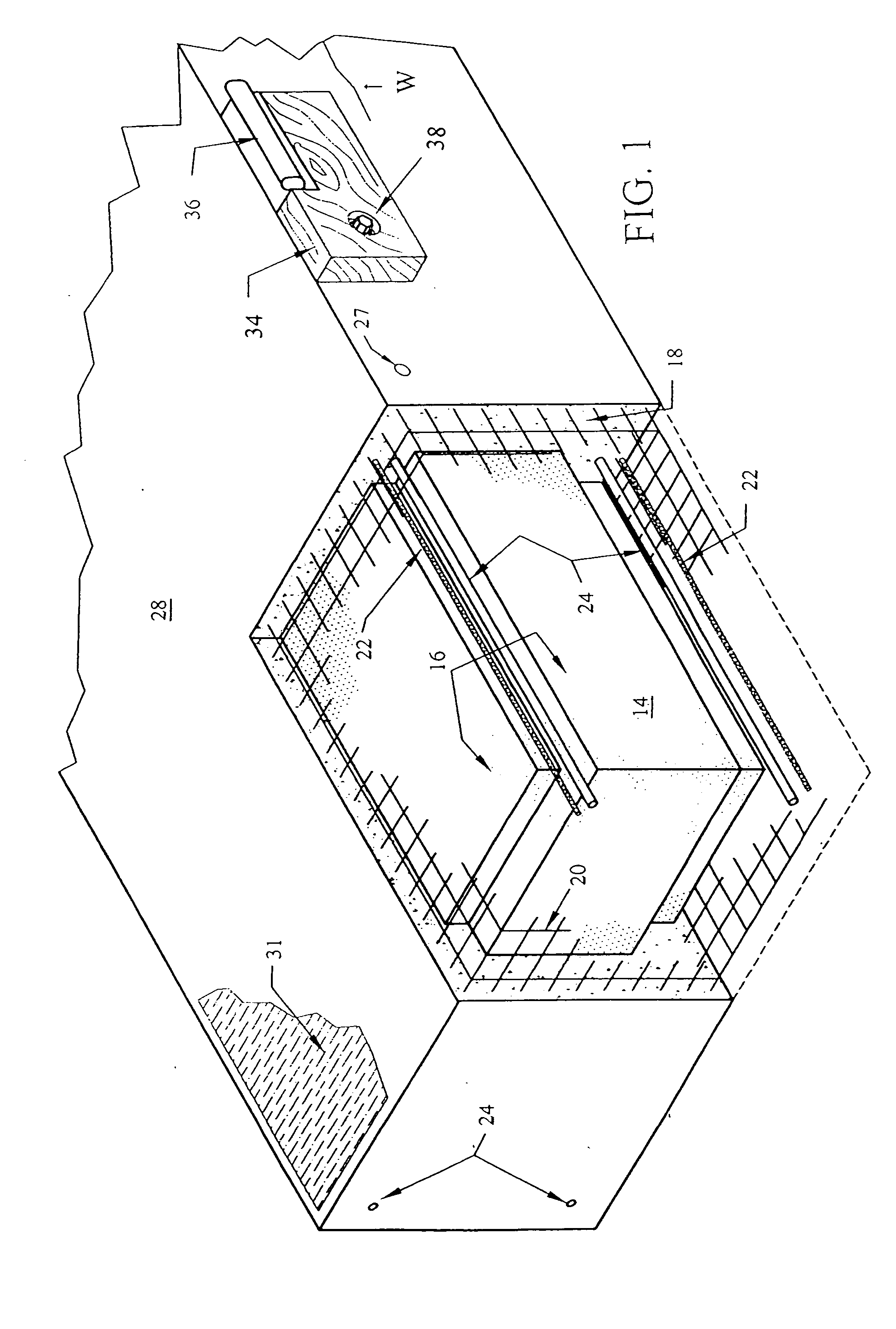

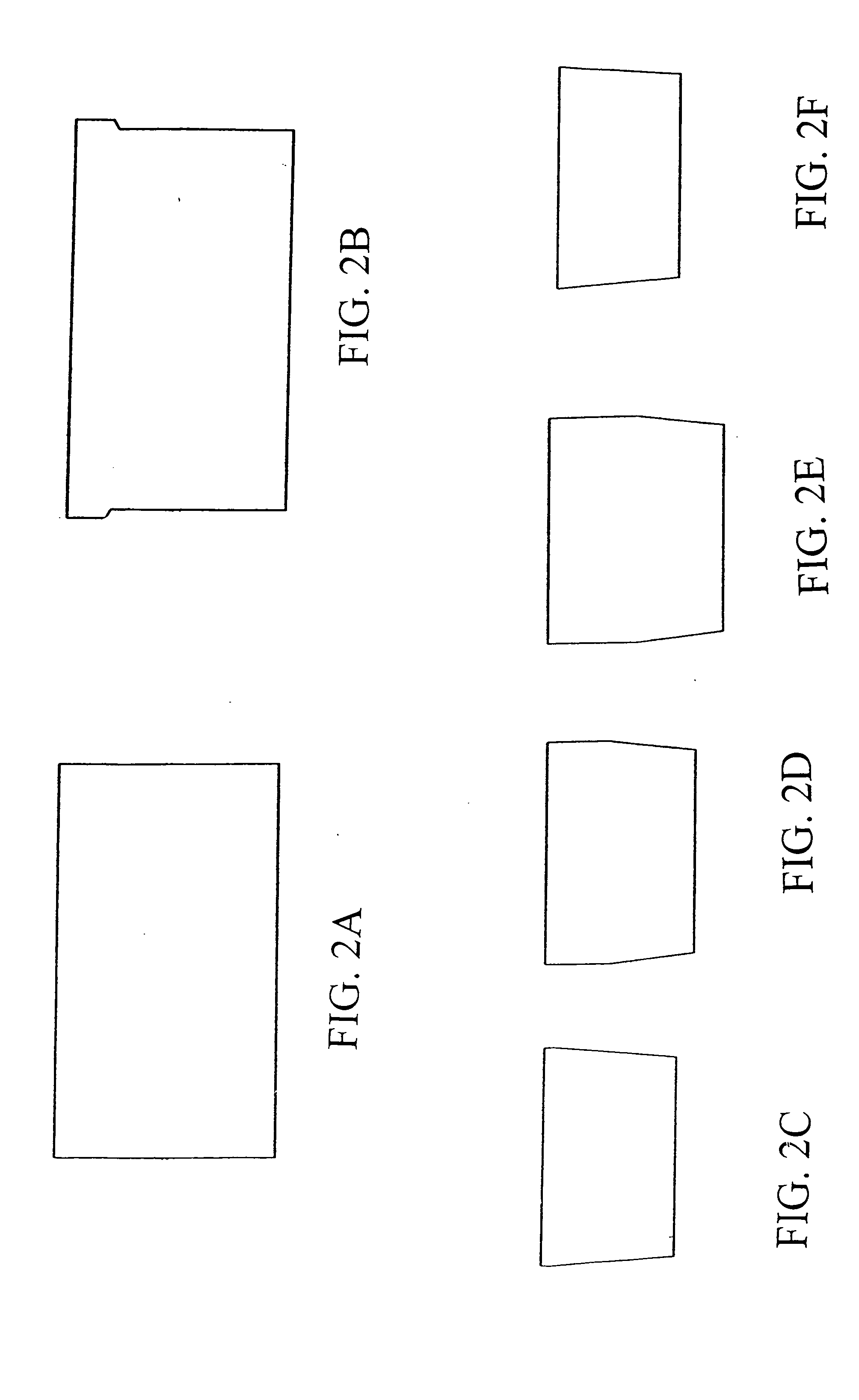

[0012] With reference to the drawings, the invention relates to a corrosion resistant prestress concrete float system featuring one or more floating units 10. Each unit 10 preferably has a cross-section configuration as depicted in FIGS. 2A-2F, but may also be configured to have other cross-sections. A plurality of the units 10 may be arranged as seen in FIG. 3 and FIGS. 5A-5B to provide a floating dock or wharf system 12.

[0013] Returning to FIG. 1, each unit 10 is constructed so as to be relatively corrosion resistant when used in a marine environment. This is accomplished in a preferred embodiment by avoiding the use of components such as steel in the construction of the units 10.

[0014] In a preferred embodiment, each unit 10 preferably includes a buoyant core 14 encased within a polymeric coating 16, concrete 18 encasing the core 14 and polymeric coating 16, a corrosion resistant mesh 20 to reinforce the concrete 18, and a plurality of corrosion resistant pretensioned fiber mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

| corrosion resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com