Fireplace grate accessory to increase burn time of synthetic log

a synthetic firelog and accessory technology, applied in the field of fireplace grates, can solve the problems of less uniformity, less attractiveness, and softening of synthetic firelogs such as duraflame® firelogs, and achieve the effects of increasing the burn time of synthetic firelogs, facilitating use, and maintaining attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

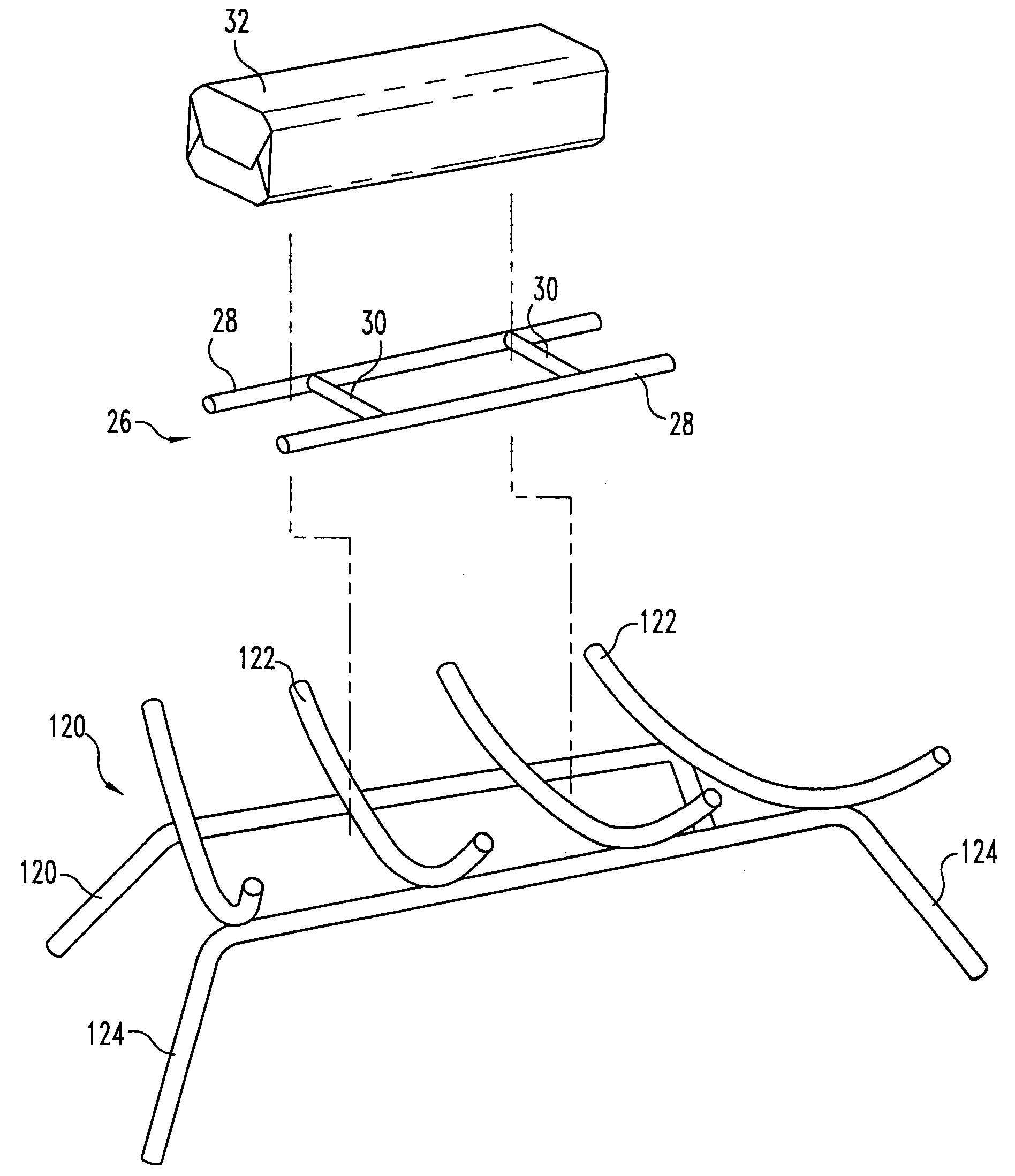

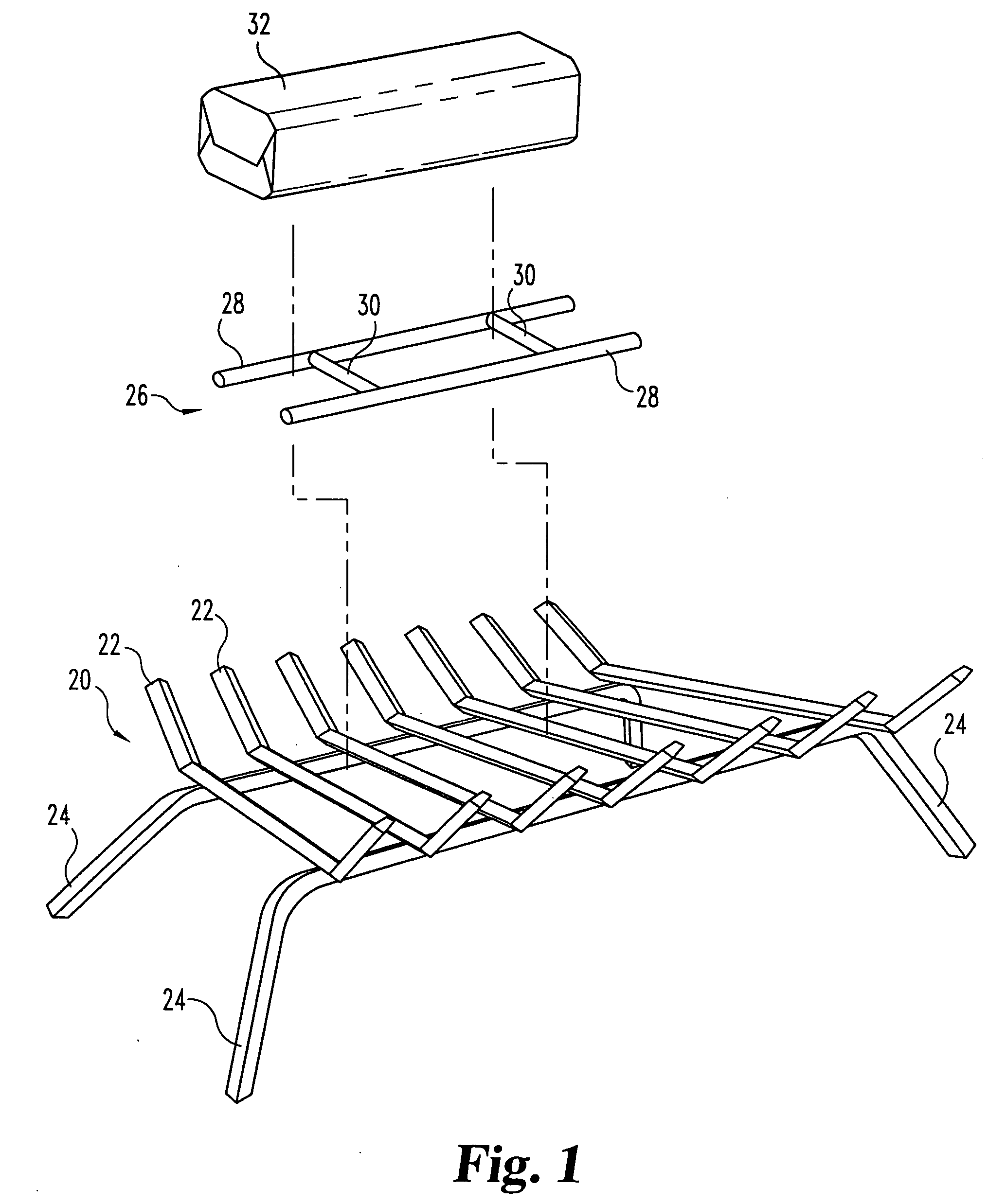

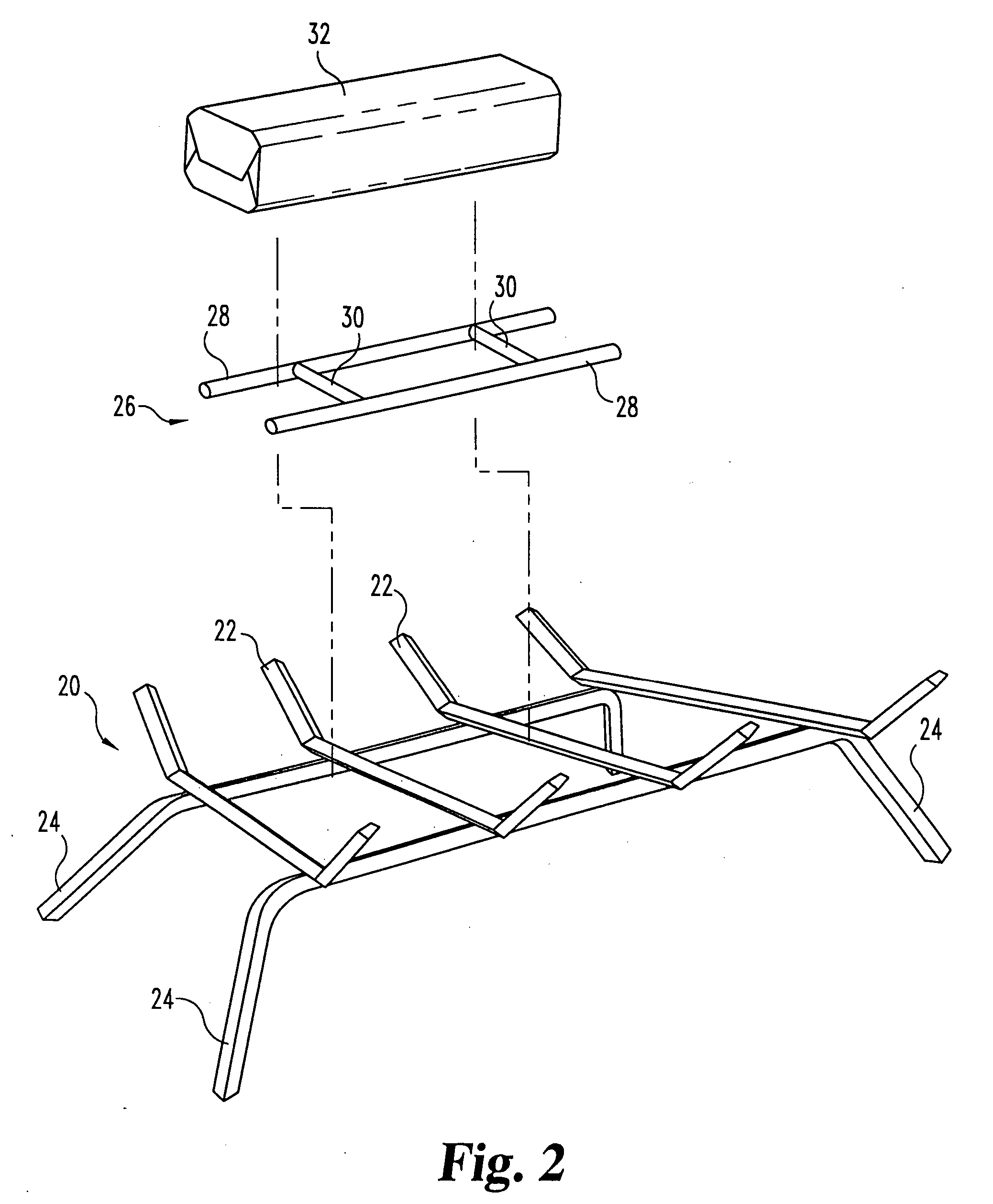

[0022] Turning to FIGS. 1 and 2, fireplace grate 20 includes substantially parallel spaced bars 22 that are adapted for supporting a log made of real wood (not shown). Bars 22 can be spaced apart anywhere from 2 to 3 inches or more, measured center to center (compare FIGS. 1 and 2 for spacing differences). Four legs 24 extend downwardly from bars 22, thereby supporting the grate away from the fireplace floor on which it sits. A grate accessory 26 rests on top of grate 20 as indicated.

[0023] Accessory 26 includes two elongate members 28 that are positioned across a portion of bars 22. As shown in FIGS. 1 and 2, elongate members 28 arc substantially parallel to one another. Members 28 are spaced apart and are connected to one another by connecting members 30. Connecting members 30 comprise a pair of spaced bars disposed between elongate members 28, the connecting members 30 being substantially orthogonal to elongate members 28 in the embodiment shown in FIGS. 1 and 2. It is envisione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com