Plastic film bag with air cushioning function

a technology of air cushioning and plastic bags, which is applied in the field of plastic film bags, can solve the problems that the bag once sealed cannot be opened, and achieve the effect of simple bag body structure and easy air injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

; See FIGS. 1-4

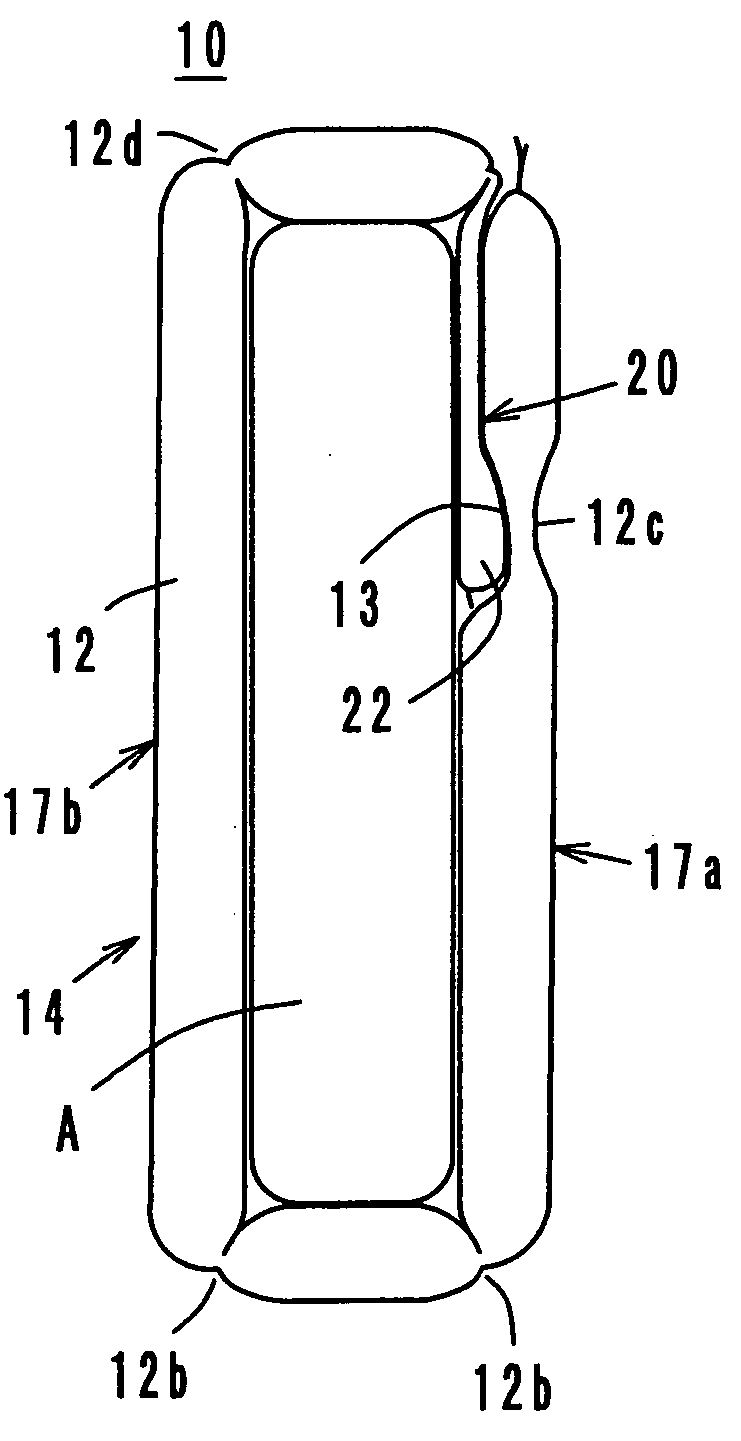

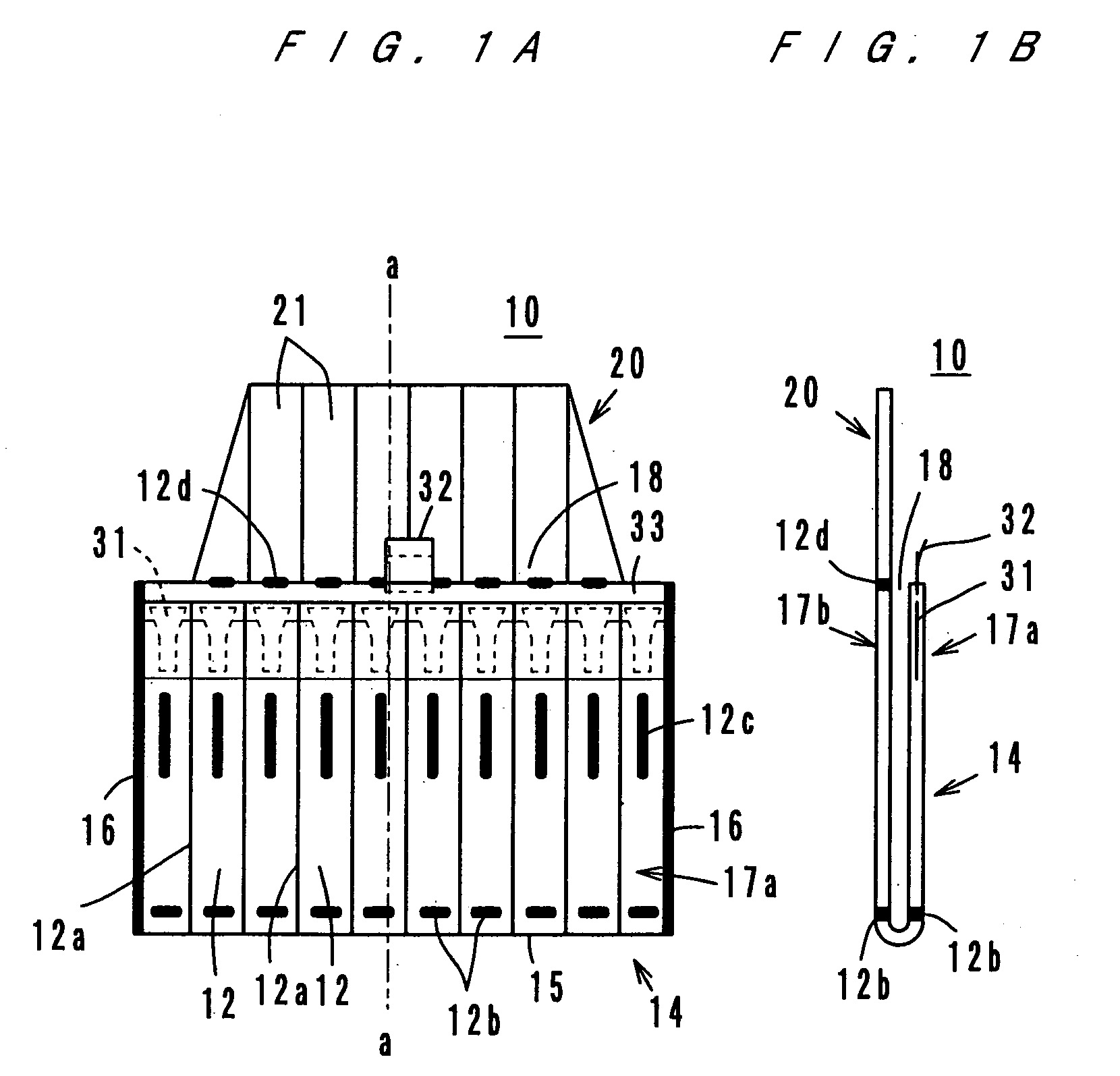

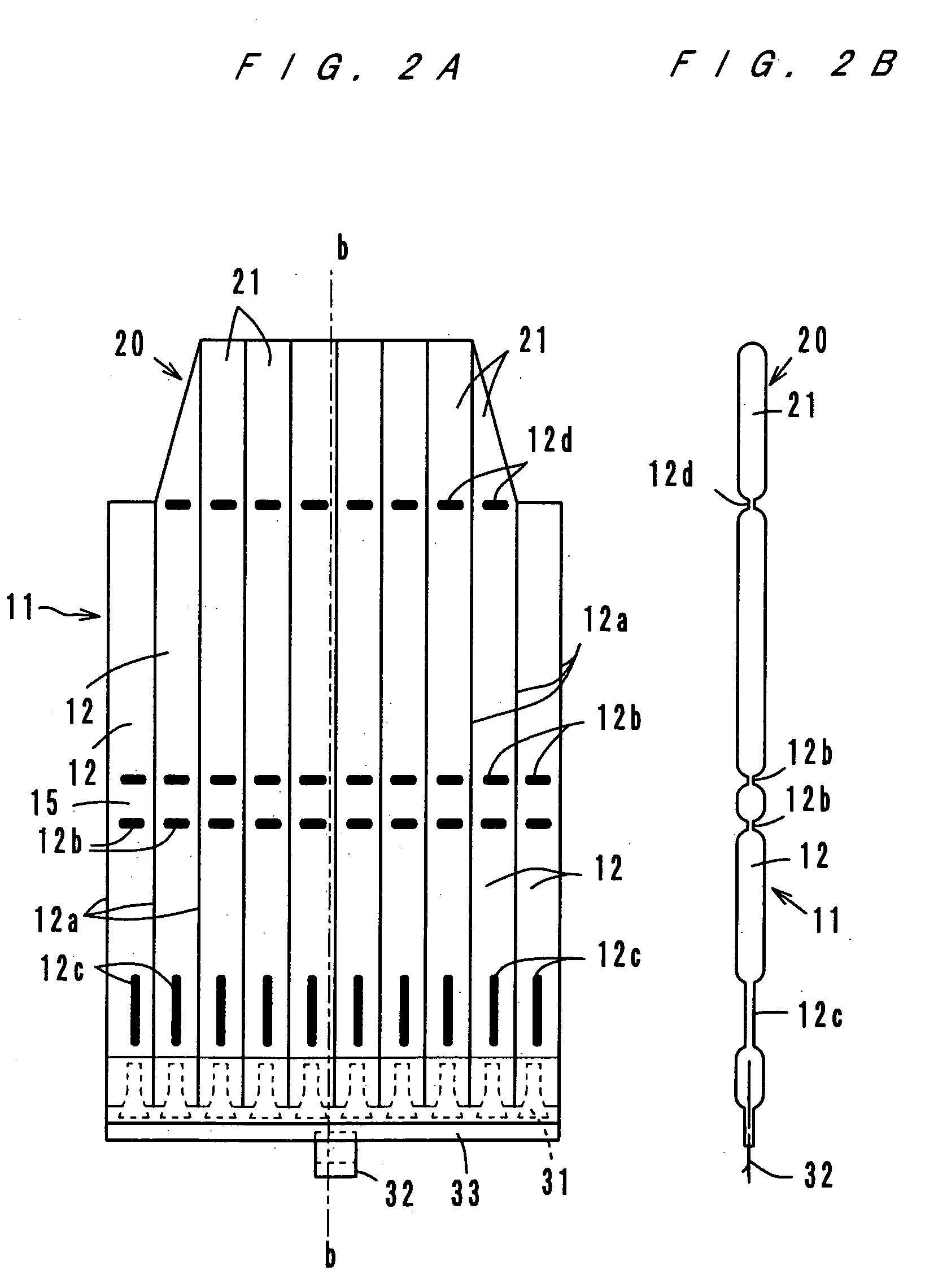

[0028]FIG. 1A is a plan view of a plastic film bag 10 according to a first embodiment of the present invention, and FIG. 2A is a developed view of the plastic film bag 10. The bag 10, as FIG. 2A shows, is made of a plastic tubular material 11 composed of a front film and a back film. By forming fused portions 12a in the tubular material 11 such that the fused portions 12a extend in the direction of the longer side of the bag 10, ten long cells 12 which are arranged in parallel in the direction of the shorter side of the bag 10 are formed. In each of the cells 12, the front film and the back film are fused together at portions 12b and 12c. FIG. 2B shows a state where the respective cells 12 are filled and swollen with air.

[0029] The tubular material 11 is folded substantially in the middle of the longer dimensions of the cells 12, and as FIGS. 1A and 1B show, the folded portions are fused together at both sides 16. Thus, a bag body 14 comprising a front side 17a, a ba...

second embodiment

; See FIGS. 6 through 8

[0043] A plastic film bag according to the second embodiment is basically of the same structure as the plastic film bag according to the first embodiment. In FIGS. 6A and 6B through 8, the same members and parts are provided with the same reference numerals as those in FIGS. 1A and 1B through 3. In the following description of the second embodiment, the point which is different from the first embodiment is described. FIG. 7B is a developed view of the bag body 14 of the plastic film bag according to the second embodiment in a state where the cells 12 and 21 are filled with air.

[0044] The feature of the second embodiment which is different from the first embodiment is that the air injection means comprises a check valve 35 which is provided on an end (the open end 18 of the front side 17a) of the bag body 14 and an air passage 36 which supplies air from the check valve 35 to the cells 12. The check valve 35 is of a well-known type which is used for air injecti...

third embodiment

; See FIGS. 9 through 11

[0046] A plastic film bag according to the third embodiment is basically of the same structure as the plastic film bag according to the first embodiment, and like the plastic film bag according to the second embodiment, this plastic film bag according to the third embodiment has one check valve 35. In FIGS. 9A and 9B through 11A and 11B, the same members and parts are provided with the same reference numerals as those in FIGS. 1A and 1B through 3 and FIGS. 6A and 6B through 8. In the following description of the third embodiment, only the points which are different from the first and second embodiments are described. FIG. 9B is a sectional view of the bag body 14 of the plastic film bag according to the third embodiment in a state where the cells 12 and 21 are filled with air.

[0047] The plastic film bag according to the third embodiment is used to contain a thin item B as shown in FIG. 11A or to contain a small item B′ as shown in FIG. 11B. The features of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com