Paint particle deflector

a technology of deflector and paint, which is applied in the direction of breathing protection, protective clothing, hats, etc., can solve the problems of light impairing particles and fluids, and achieve the effect of improving the safety of workers and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

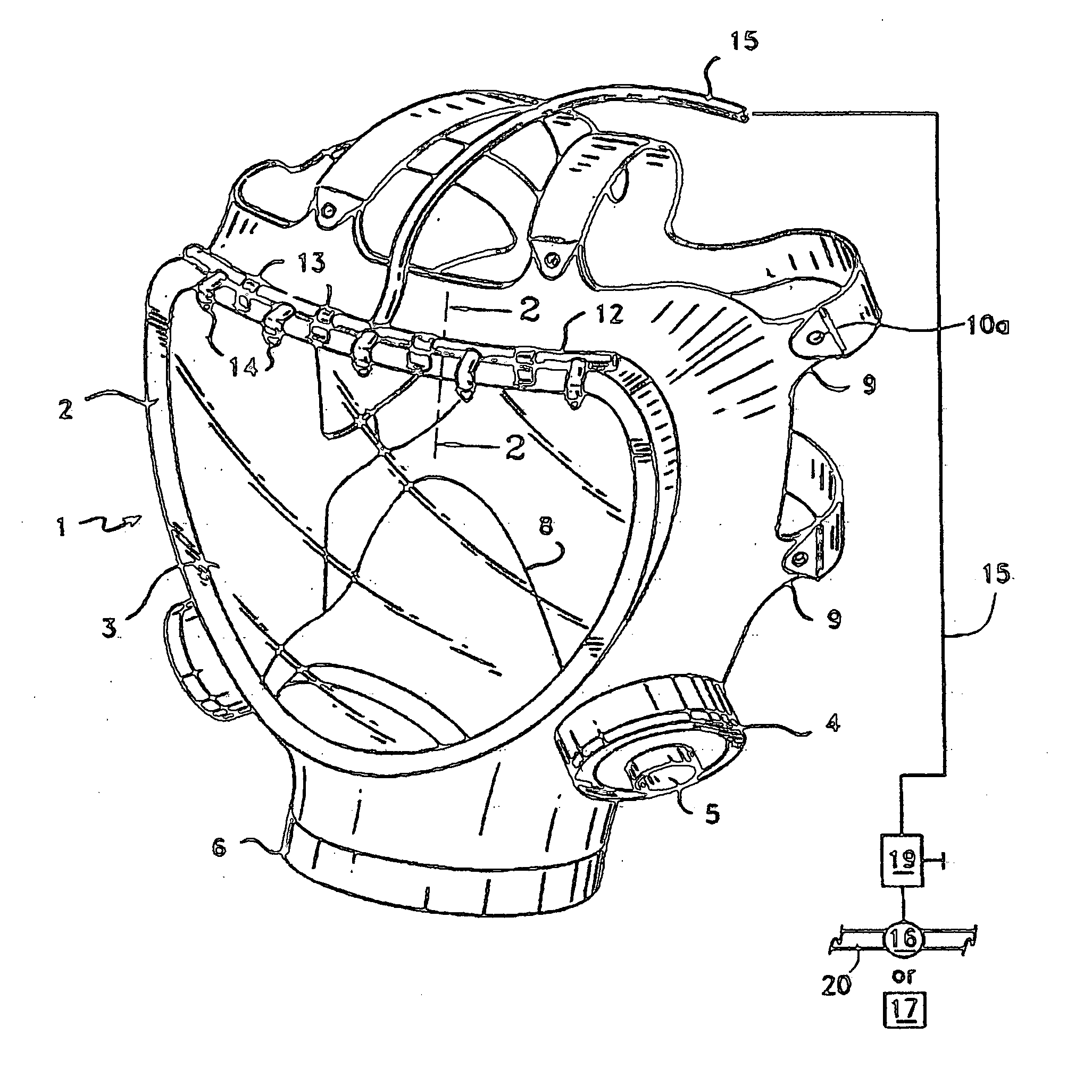

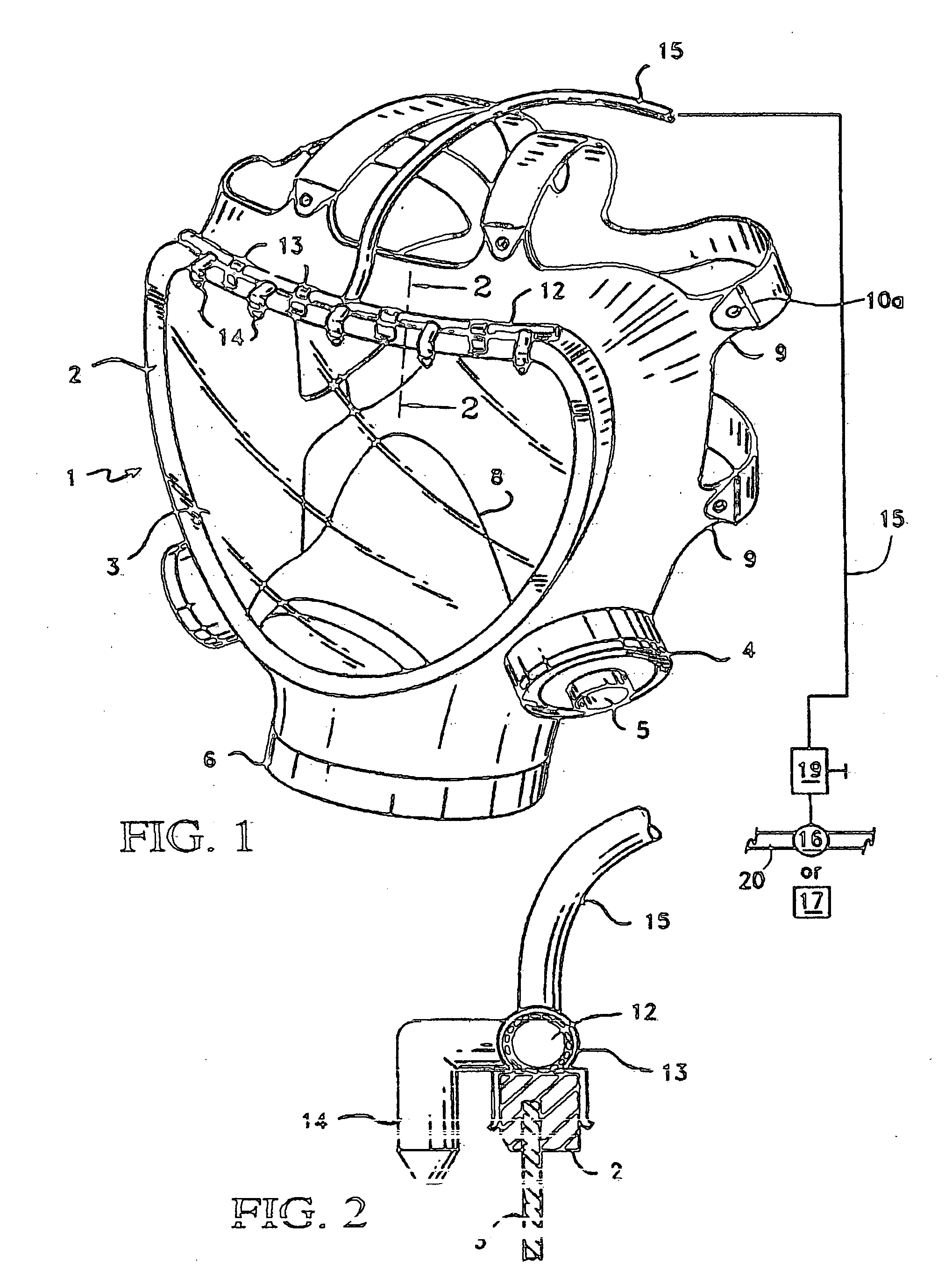

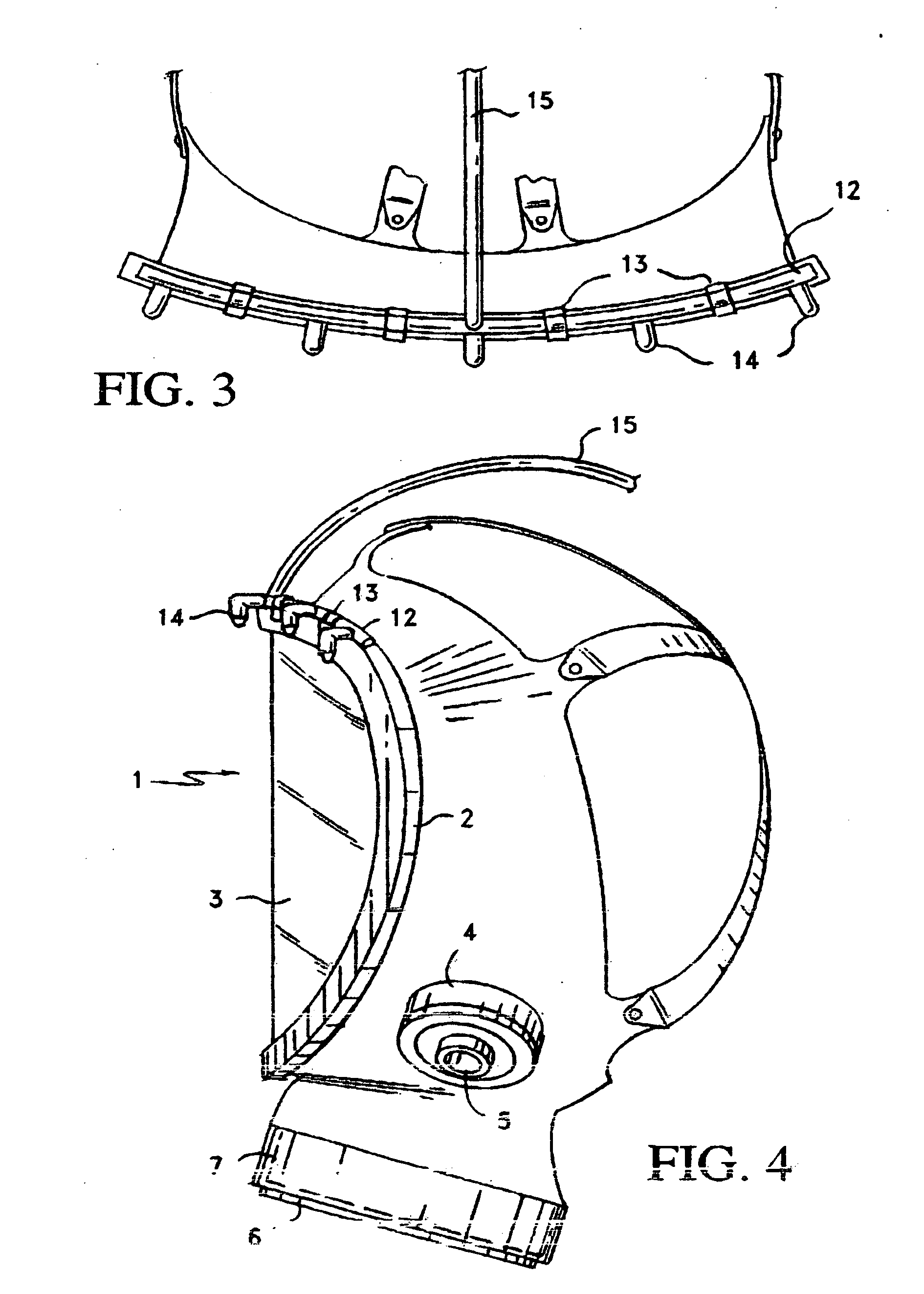

[0022]FIG. 1 shows a rubber frame that constitutes a shielding mask 1 having a gasket 2. Adhesively fitterd within the gasket is a concave lens or glass shield 3. At the sides near the lower end of the mask adjacent the gasket are two cylindrical projections 4 that contain an air inlets 5. Between the two outlets and front and center is a larger cylindrical projection 6 that is enclosed by a filter 7 for receiving incoming air. The filter projects inwardly and a nose piece 8 is attached around the thinner edge of the cylinder. Integral with an inner edge of the gasket are 6 tabs 9 to which an equal number of adjustable straps 10 are secured by a conventional snap button 10a. There are two straps on each upper and lower side and two straps extend from the top. All the straps intersect at a somewhat hexagonically shaped piece 11 located about the mid region in the back of the head. The straps secure the mask to the head. A ¼″ copper tube 12 is fastened in an arc with spring clips 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com