Structure of heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

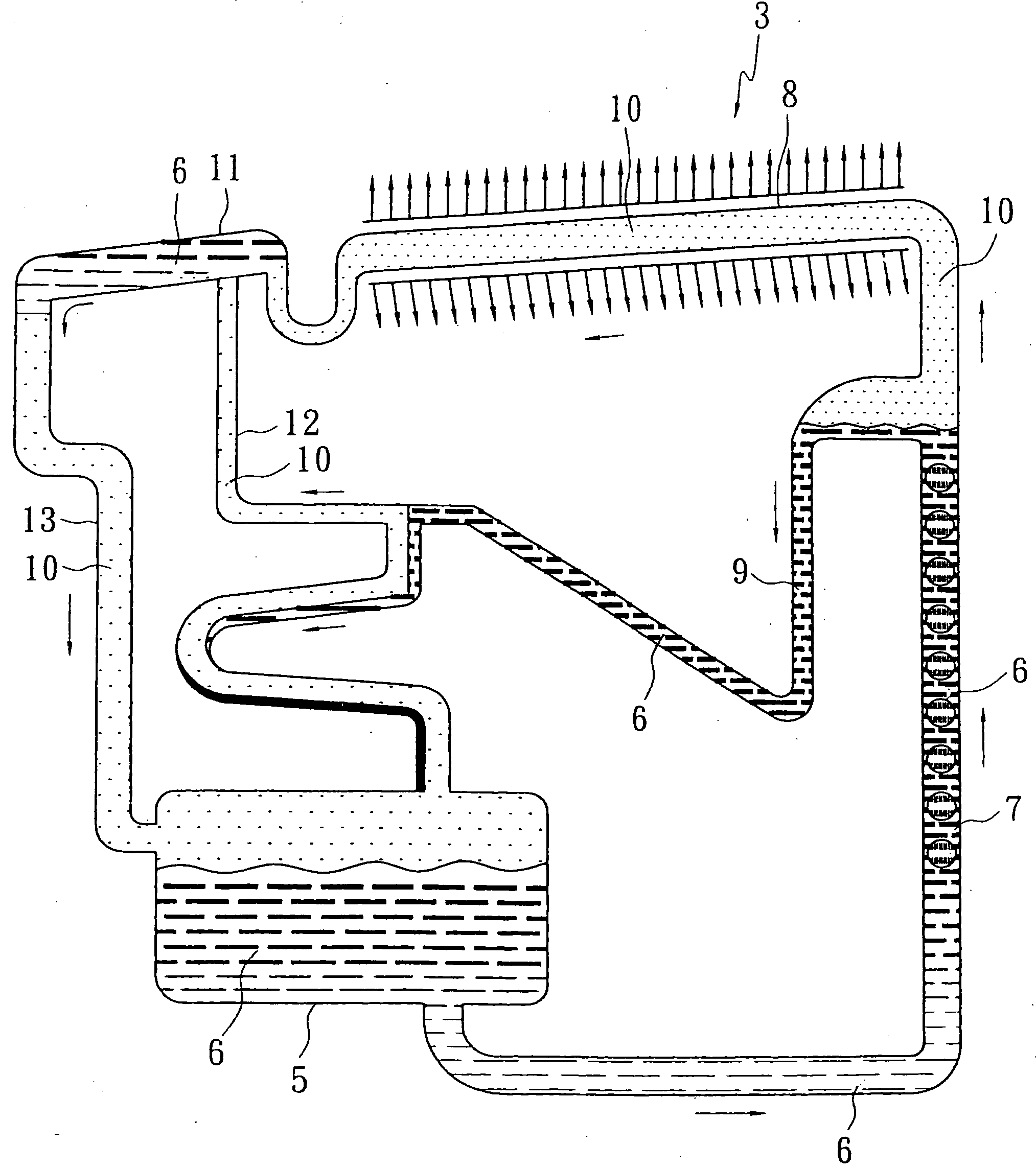

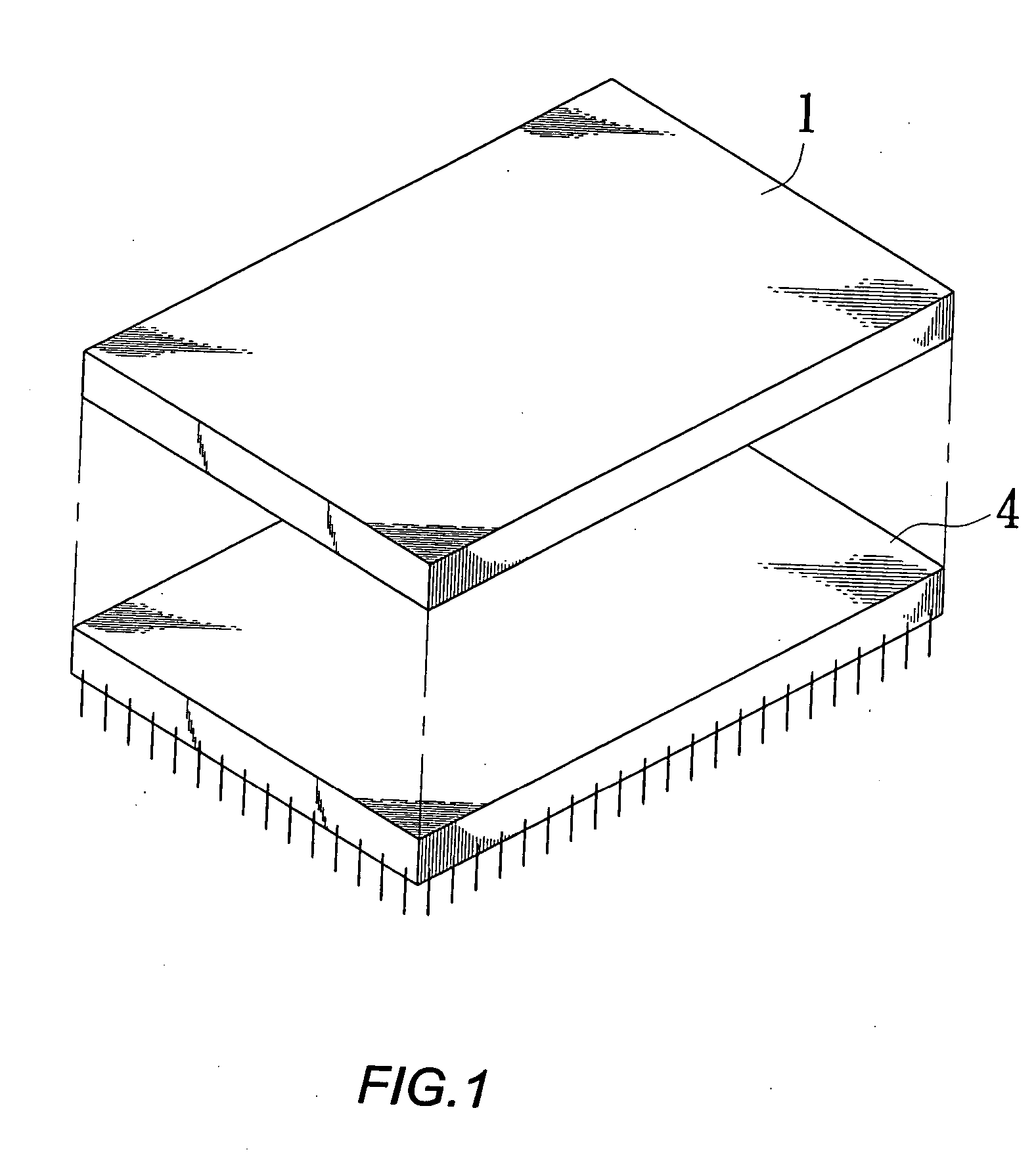

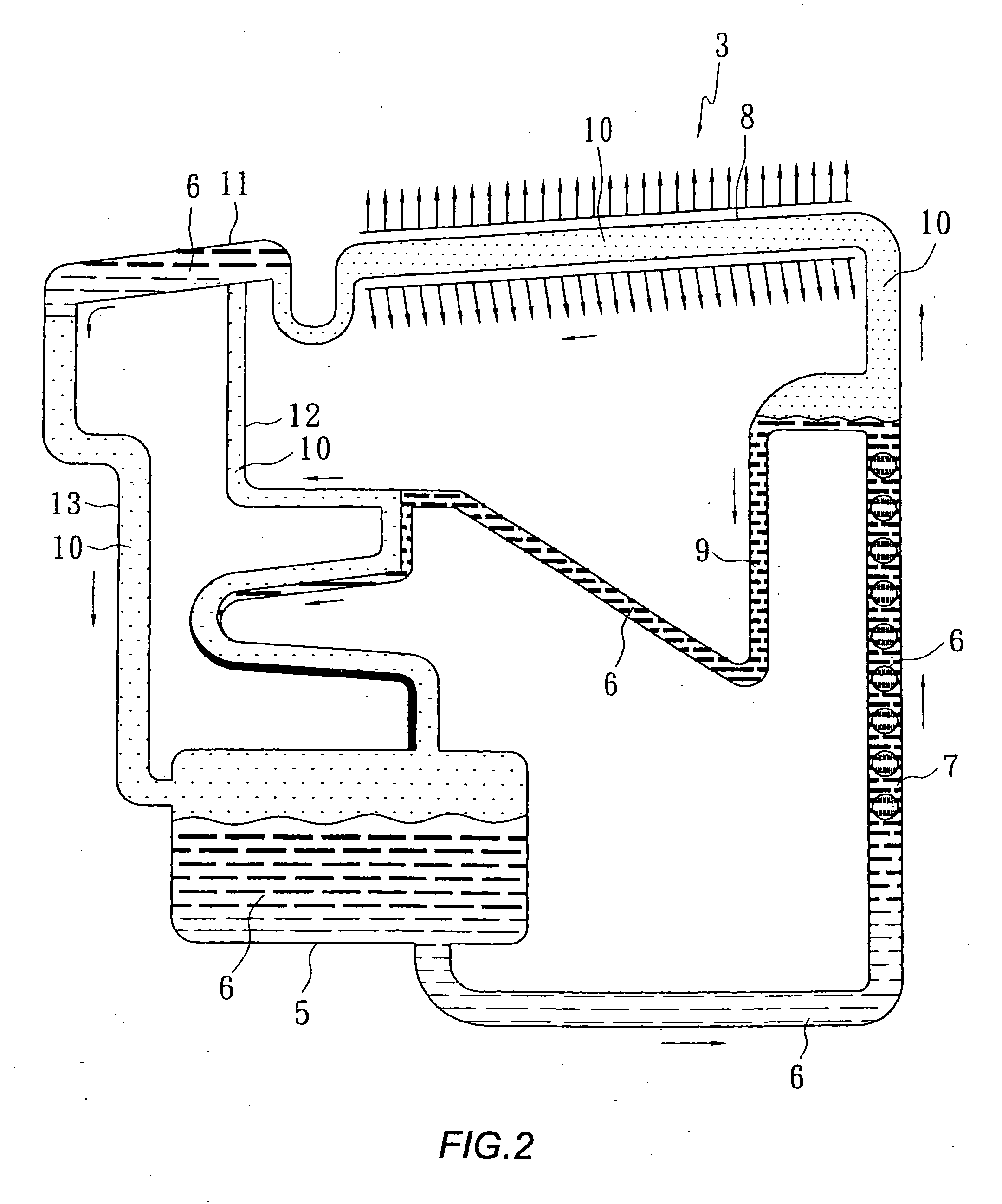

[0008] As showing in FIGS. 1 and 2, an improved structure of heat sink (1) of the present invention is combined with the base (2) and the structure of the closed mini pipeline (3). Within the length and width of the base (2) are in accordance with some machine elements (4) causing waste heat for connecting closely with said machine elements (4) as a whole. By way of the cooling effect produced when the solution in the pipeline of the structure of closed mini pipeline (3) connecting with the base (2) circulate and change mutually in the liquid state and steam, which makes some machine elements (4) in machinery or electronic products running to produce waste heat cooling.

[0009] As showing in FIG. 2, the structure of the closed mini pipeline (3) of the present invention is a circulating network of the closed mini pipeline. Within the liquid tank of concentrated solution (5) contains the mini liquid (6) low the atmosphere pressure is through the generator (7). Liquid in the pipeline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com