Printing system

a printing system and bar code technology, applied in the field of printing systems, can solve the problems of difficult to ensure the consistency between the rfid data (electronic information, fear of damage to the rfid tag), and the content of the bar code cannot be recognized by human beings by glancing at the bar code, so as to prevent the damage of the rfid chip, prevent the rfid tag from being damaged, and suppress the temperature rise of the r

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

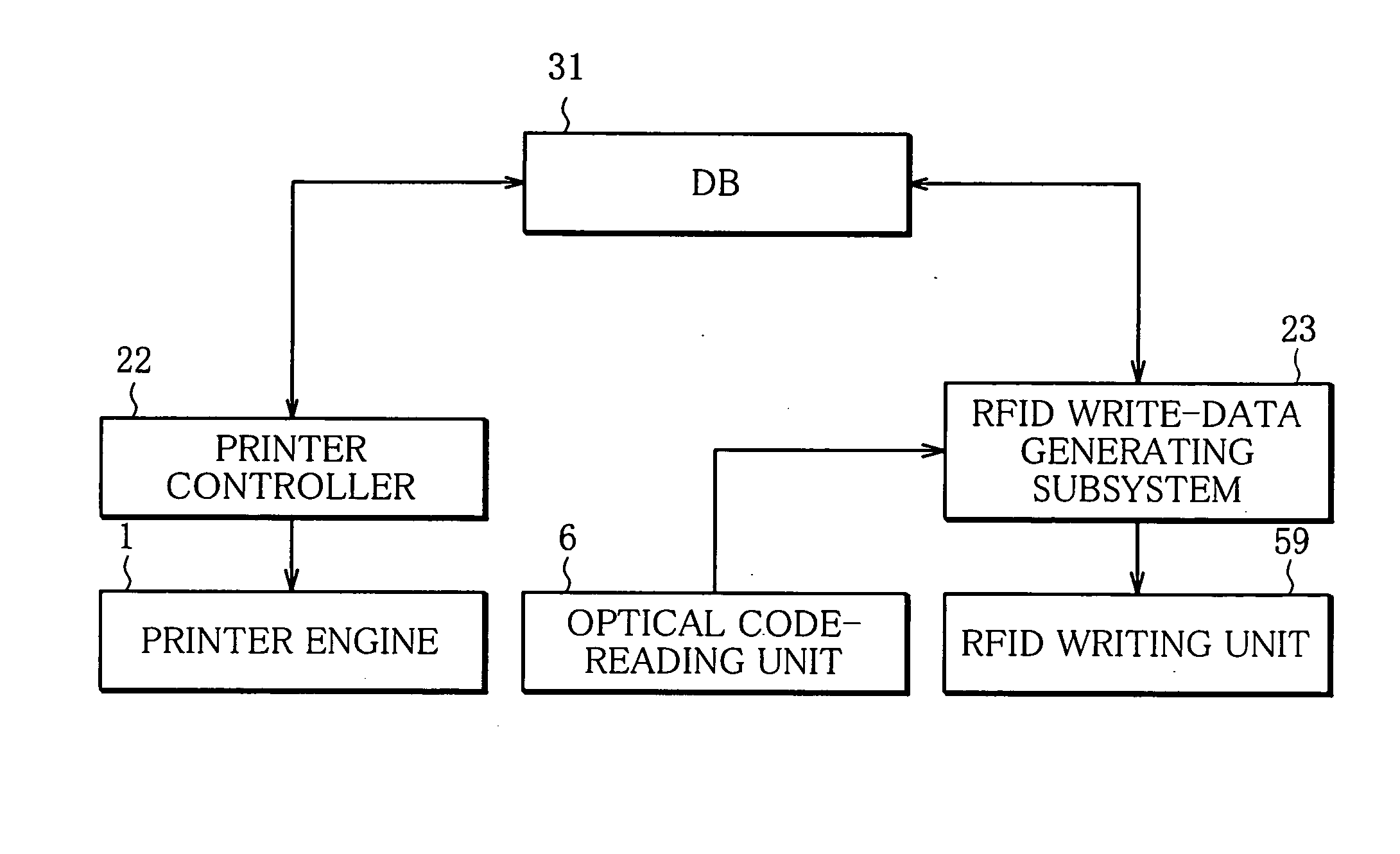

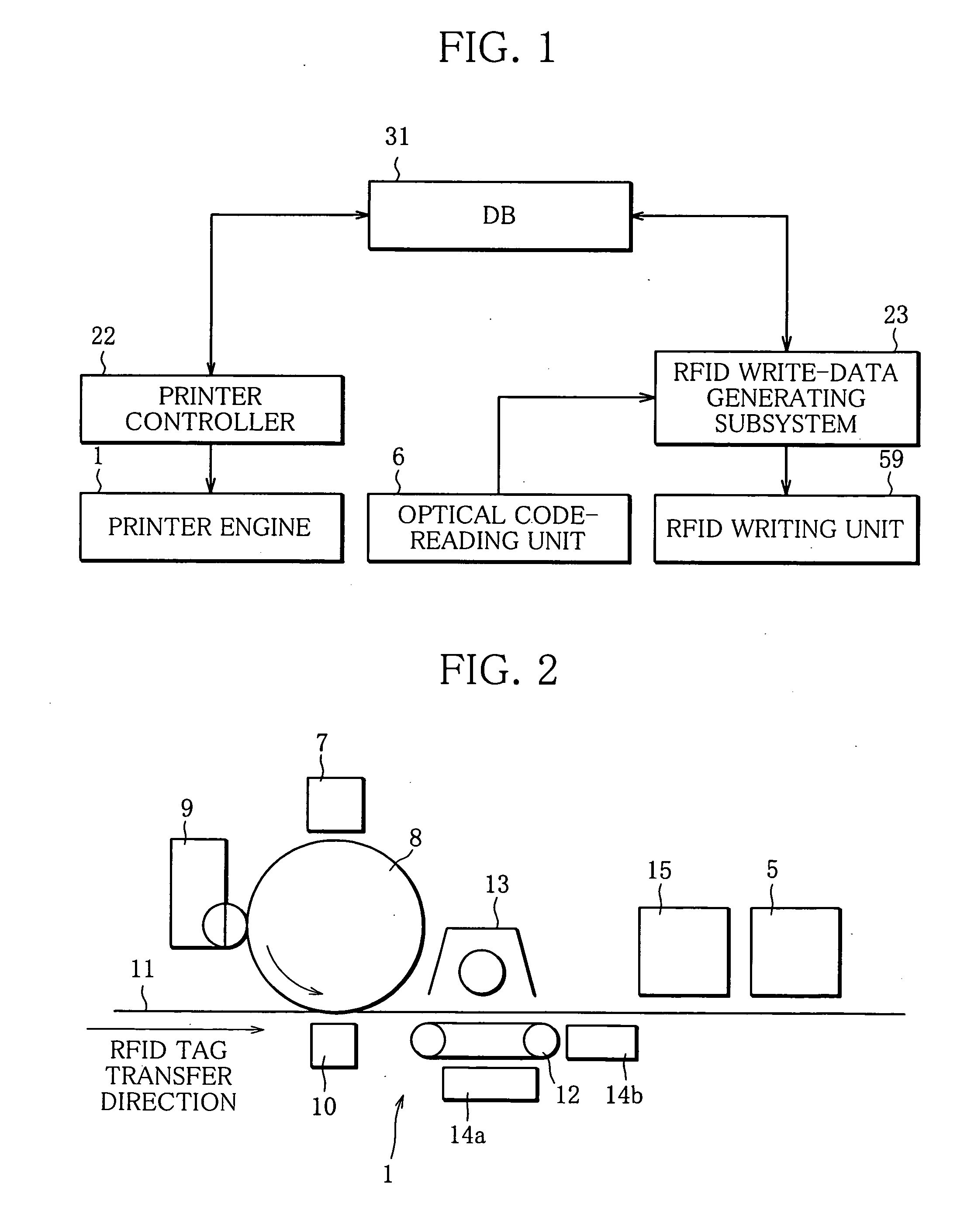

[0050] With reference to FIGS. 1-7, a printing system according to this invention will be explained. This printing system is suitable for preparation of packing slips for home delivery service that are used at the time of delivery of goods in large quantity from a department store or a mail-order selling company.

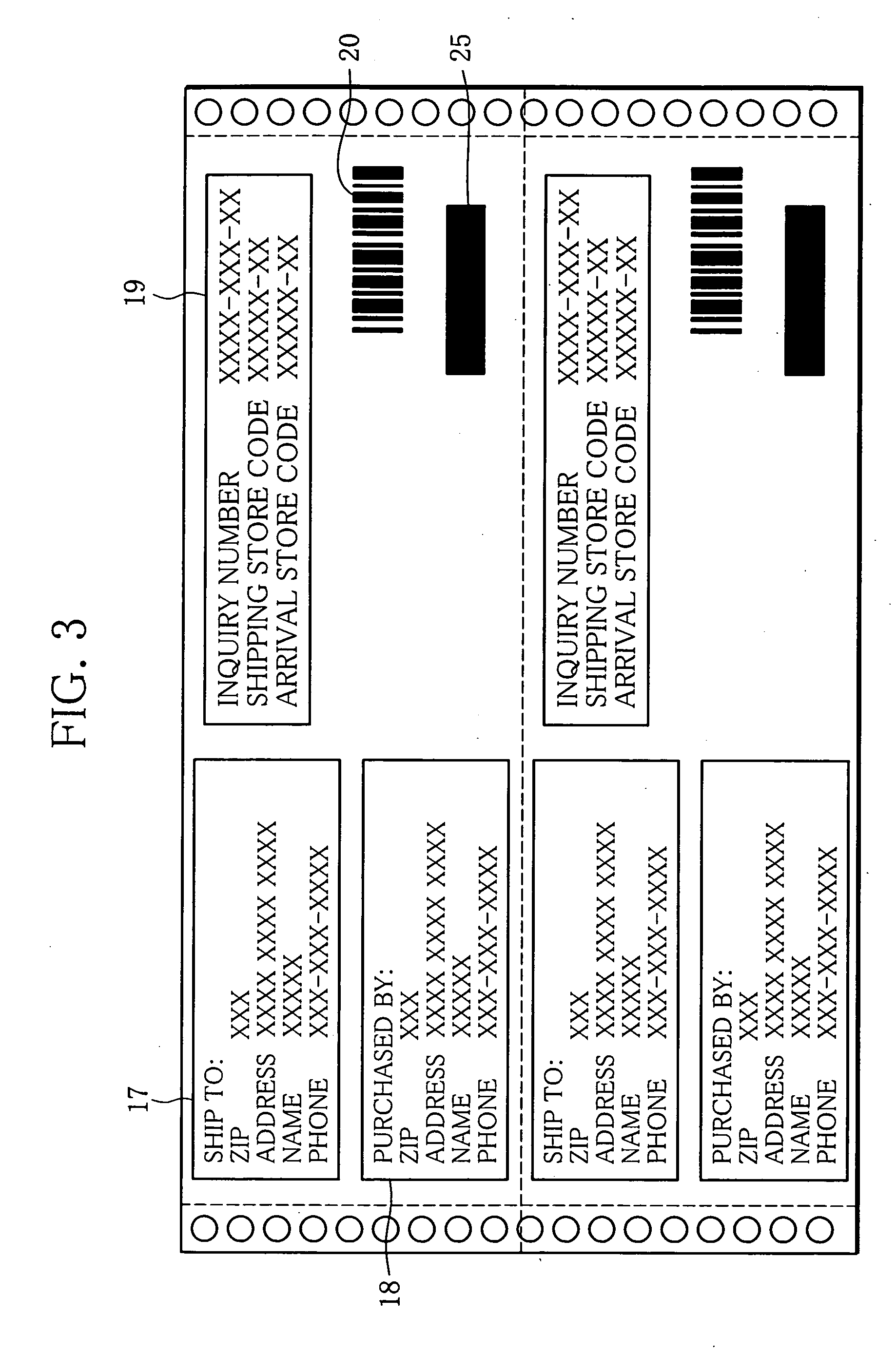

[0051]FIGS. 1 and 2 are a block diagram and a schematic structural view of the printing system, respectively. In this printing system, an electrographic printer engine is adopted as shown in FIG. 2. FIG. 3 shows an example of an RFID tag 11 used in the printing system, and FIGS. 6 and 7 show another example of the RFID tag 11. As shown in FIG. 7, the RFID tag 11 comprises a print-information recording medium 24 (hereinafter sometimes referred to as print medium) on which an RFID chip 25 is carried.

[0052] Meanwhile, although the RFID chip 25 is carried on the print-information recording medium 24, and the recording medium 24 per se constitutes the RFID tag 11 in this embodim...

second embodiment

[0072] In the following, a printing system according to this invention will be explained with reference to FIGS. 8 and 9.

[0073]FIGS. 8 and 9 are a block diagram and a schematic structural view of this printing system. In FIGS. 8 and 9, the same elements as those shown in FIGS. 1-7 are denoted by the same numerals.

[0074] Unlike in the printing system of the first embodiment where the RFID data consistent with the code information already printed on the RFID tag 11 is written into the RFID tag 11, in the printing system of the second embodiment, the RFID data is first read out from the RFID tag 11 written in advance with the RFID data. Then, the image information and / or the code information associated with the RFID data is printed on the RFID tag 11. As in the case of the first embodiment, the printing system of the second embodiment is suited, for example, to prepare packaging slips for home delivery service that are used for goods delivery in large quantity from a department store ...

third embodiment

[0078] In the following, with reference to FIGS. 10 and 11, a printing system according to this invention will be explained.

[0079]FIGS. 10 and 11 are a block diagram and a schematic structural view of the printing system, respectively. In FIGS. 10 and 11, the same elements as those shown in FIGS. 1-9 are denoted by the same numerals.

[0080] The printing system of the third embodiment is basically the same as that of the second embodiment, but differs therefrom in that the consistency between electronic information and print information is verified.

[0081] Specifically, as in the second embodiment, the printing system of third embodiment is adapted to read out the electronic information (RFID data) from the RFID tag 11 in which such data is written beforehand, and print the image information and / or the code information associated with the RFID data onto the RFID tag 11. This printing system is suited to prepare packaging slips for home delivery service that are used for goods deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com