Vacuum cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

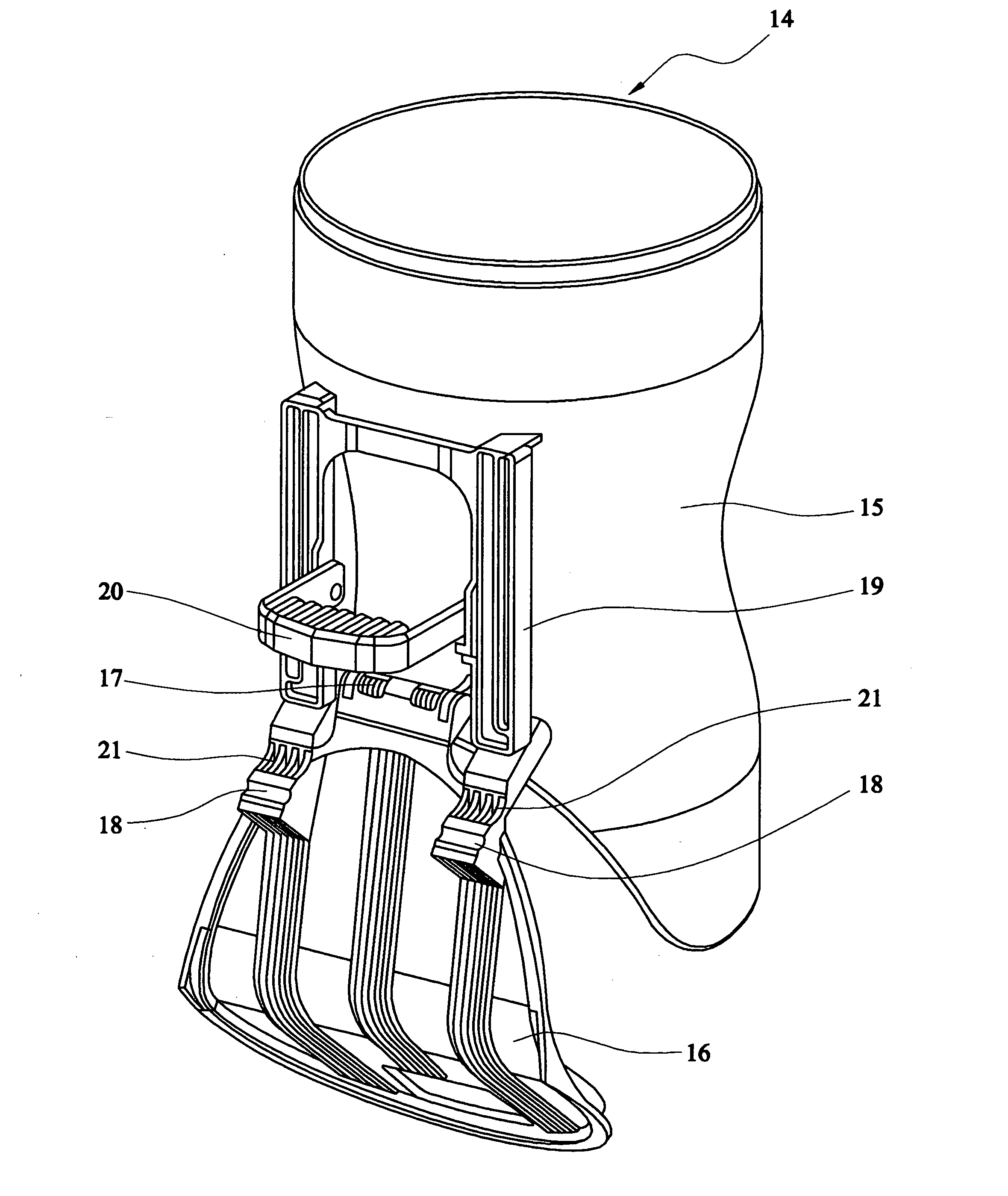

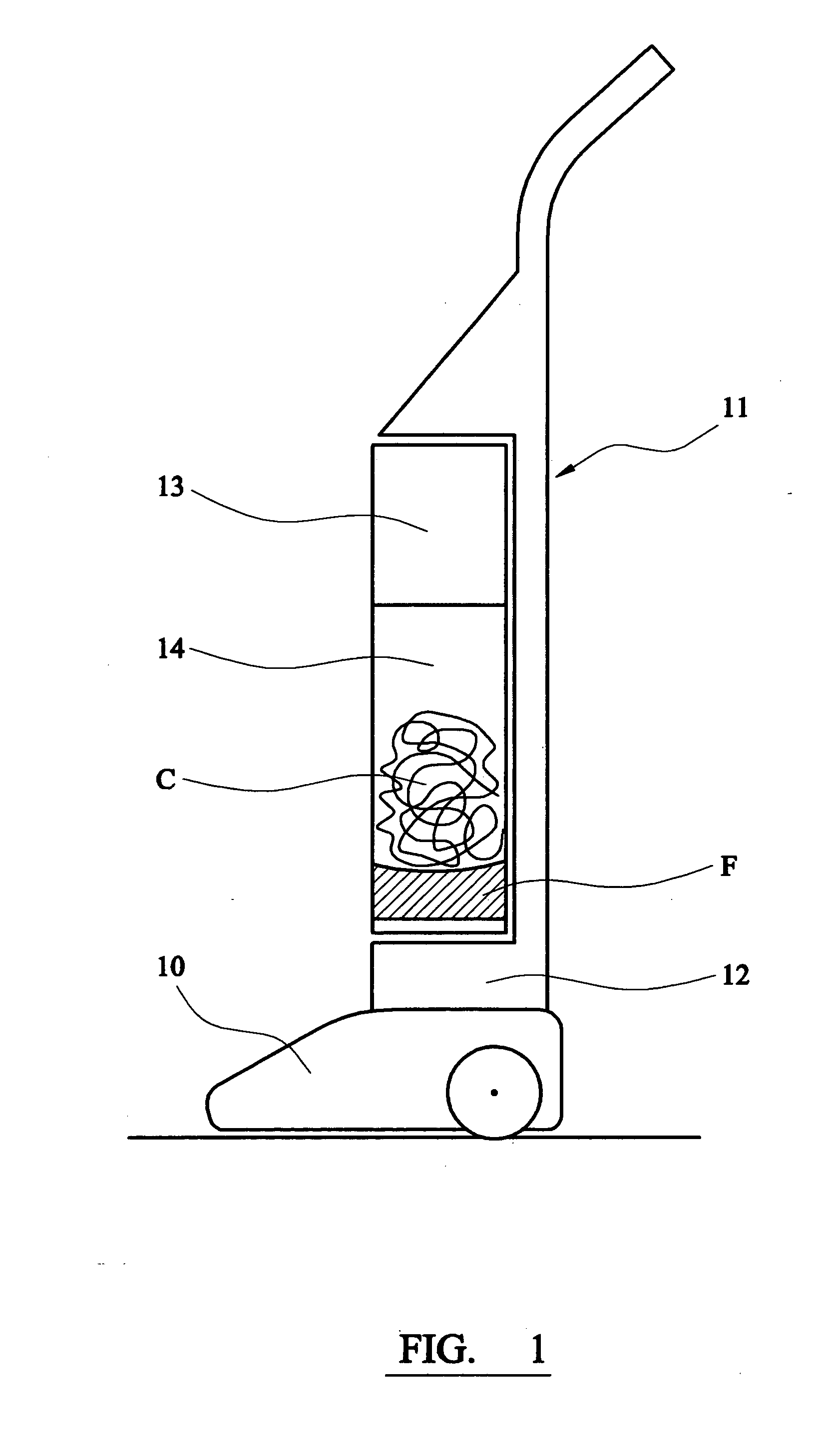

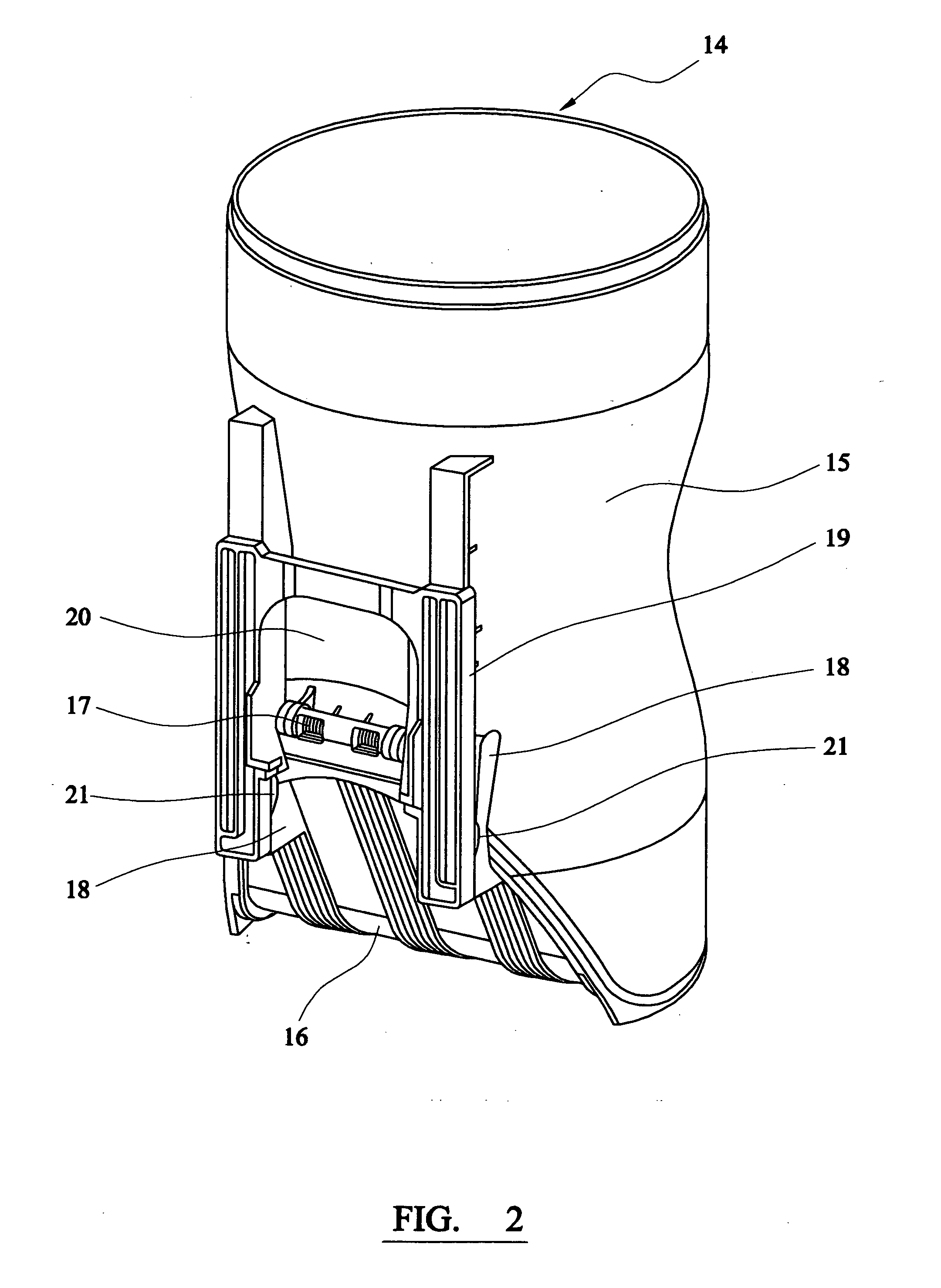

[0046] Referring to FIG. 1 of the drawings, there is shown an upright vacuum cleaner comprising a wheeled suction head 10, to which a body portion 11 is pivoted for movement between an upright position and an inclined operative position. A motor and fan are mounted in a bottom portion 12 of the body 11 of the cleaner.

[0047] A separation unit 13 mounted in the body 11 of the cleaner comprises a cyclone separator and a filter. In use, the fan induces an airflow through the cleaner from the suction head 10 through the separation unit 13, where dirt and dust separated from the airflow by the cyclone is collected in a removable dirt collection bin 14 mounted directly below the separation unit 13. The cyclone separator comprises a cylindrical wall and for practical purposes, the side wall of the collection bin 14 is a downward extension of the wall of the cyclone.

[0048] The cyclonic separation action causes the finer dirt particles F to collect at the bottom of the collection bin 14 bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com