Method and system for producing dressing products of polymer fibres useful for covering moist wounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

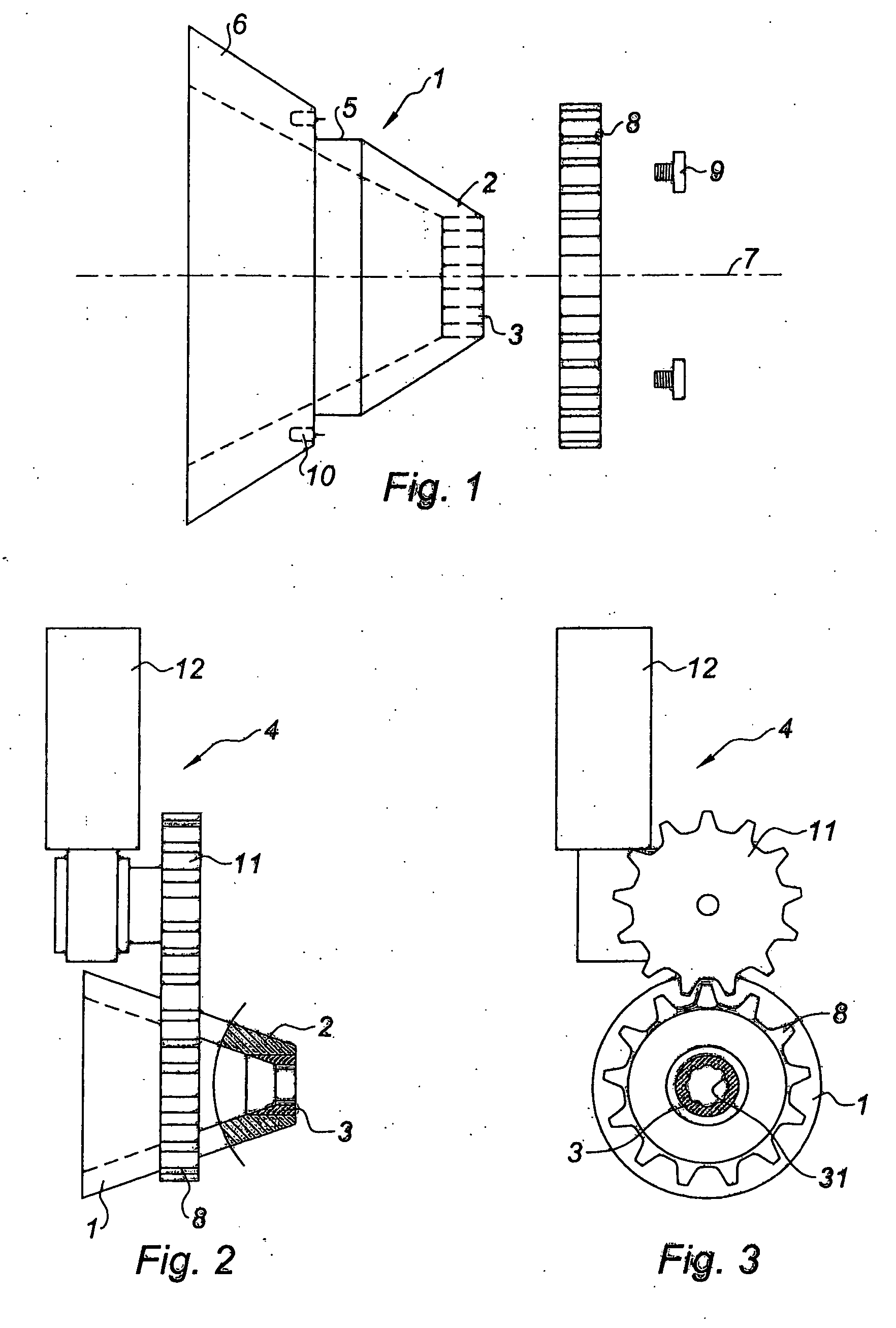

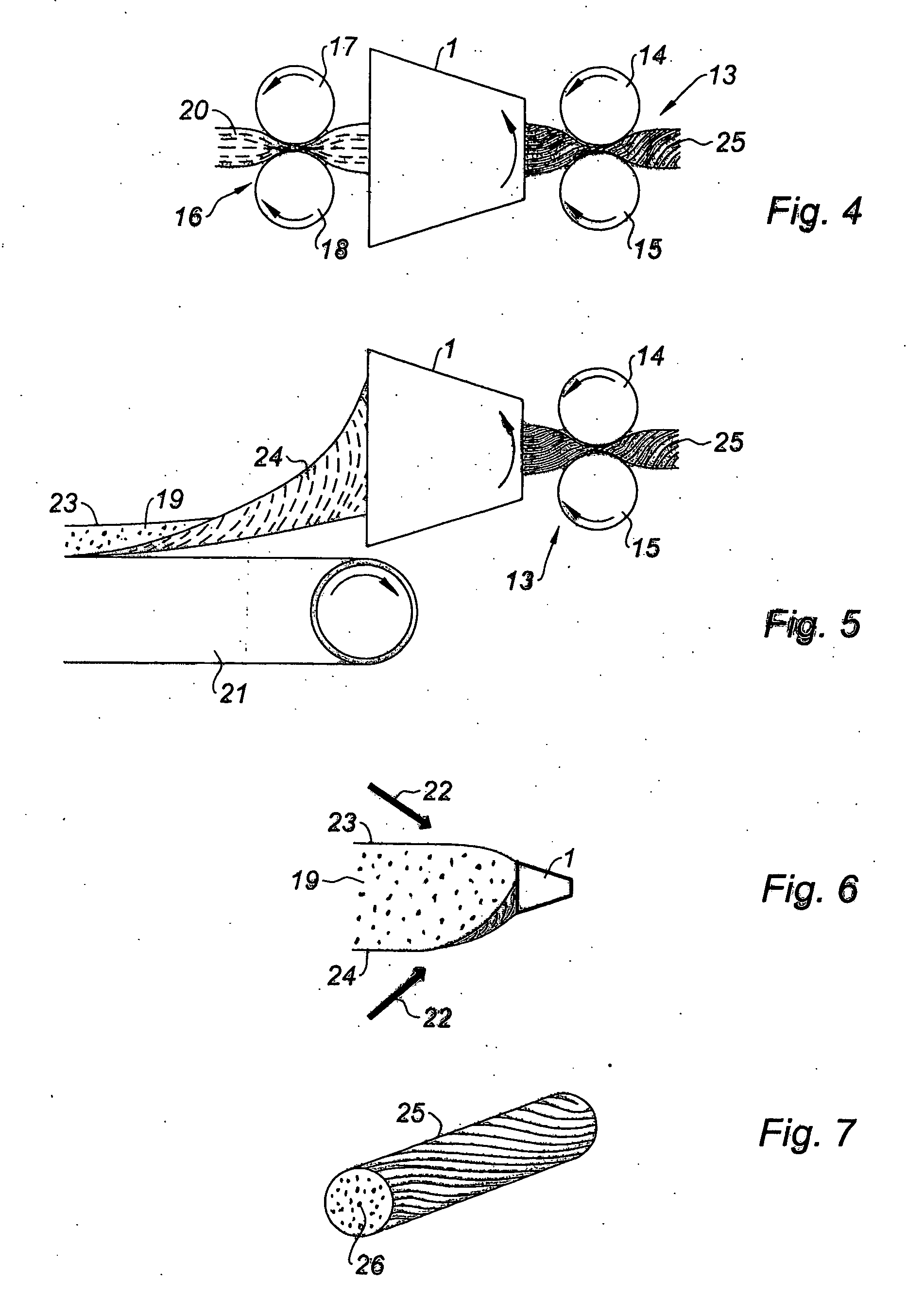

[0029] The equipment for twisting the fibres will now be described with reference to FIGS. 1-5. As illustrated in FIG. 1, the equipment comprises a bowl 1, which drives the fibres in rotation, and which can also be referred to as a funnel, of conical shape, made of plastic or of metal, having a twisting die 3 in its narrowed downstream part 2. The whole arrangement can be referred to as a whistle. The bowl 1 can be driven in rotation by a gear mechanism 4, as shown in FIG. 2.

[0030] An annular shoulder 5 is formed in the wall 6 of the bowl 1, overall in a transverse plane perpendicular to the axis 7 of the bowl 1, in order to receive the driven pinion 8 of the gear mechanism 4. The driven pinion 8 is fixed by screws 9 which are screwed into orifices 10 in the wall 6 of the bowl 1. The driven pinion 8 meshes with a driving pinion 11, itself driven by a motor 12, so as to form a wheel gear 8, 11.

[0031] In some embodiments, in place of the wheel gear 8, 11, a drive belt is mounted aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com