Automatic injection device

a technology of automatic injection and injection device, which is applied in the field of contrast medium injection device, can solve the problems of complex valve switching operation, poor device configuration balance, and sometimes forgotten switching operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

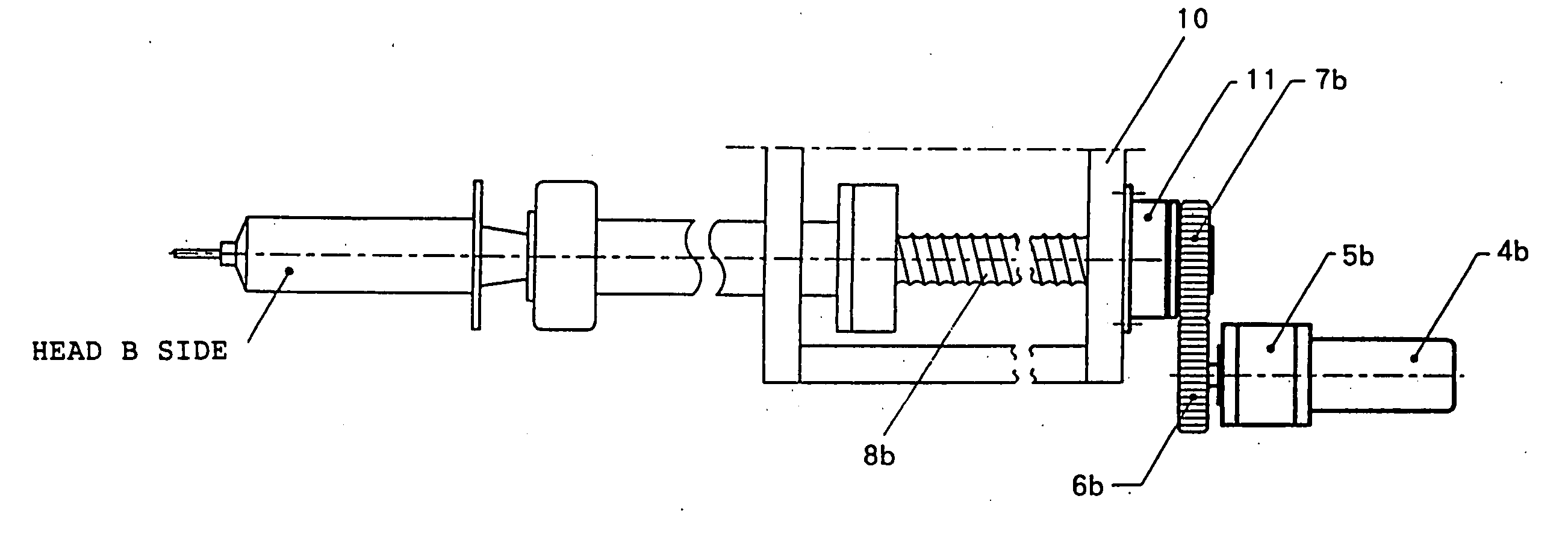

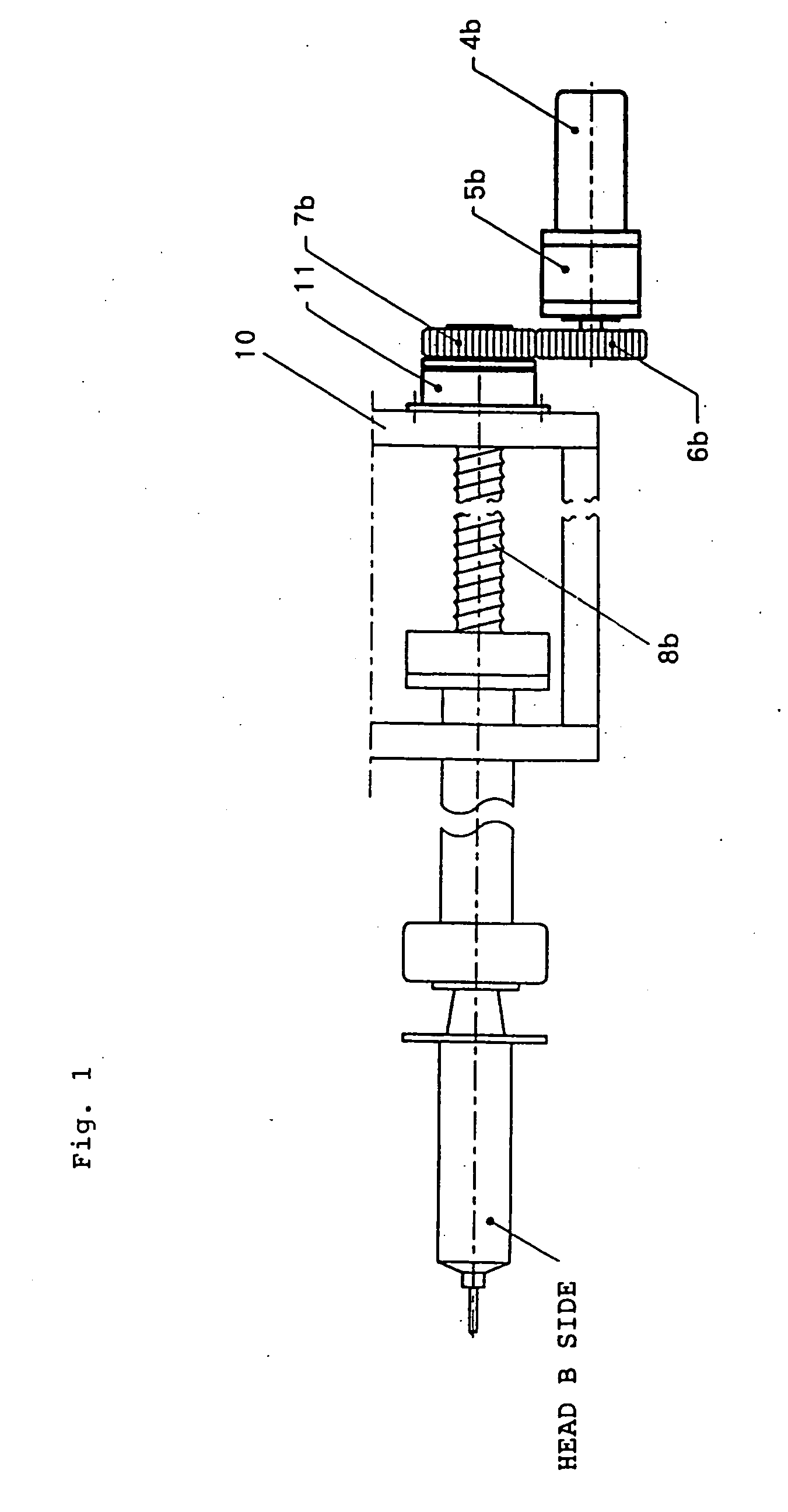

[0054] An example using an electromagnetic brake as backward-moving prohibition mechanism will be described below with reference to FIG. 1.

[0055] In this example, the main body of the electromagnetic brake 11 is fixed to a frame unit 10, while the axis (to which a screw gear 7b is fixed) of a ball screw 8b is fixed to an armature side of the electromagnetic brake. Linking and separation between the main body and the armature is performed by controlling the coil inside the electromagnetic brake.

[0056] When a syringe piston at the side of the head B is moved forward of backward, the main body and the armature are separated each other (i.e. contact is released), thereby the ball screw 8b can rotate freely by receiving the rotation of a motor 4b. When the electromagnetic brake is turned on, the main body and the armature is linked (i.e. contact is attained), thereby the rotation of the axis of the ball screw 8b is fixed. Hence, if the electromagnetic brake is turned on when the syring...

embodiment 2

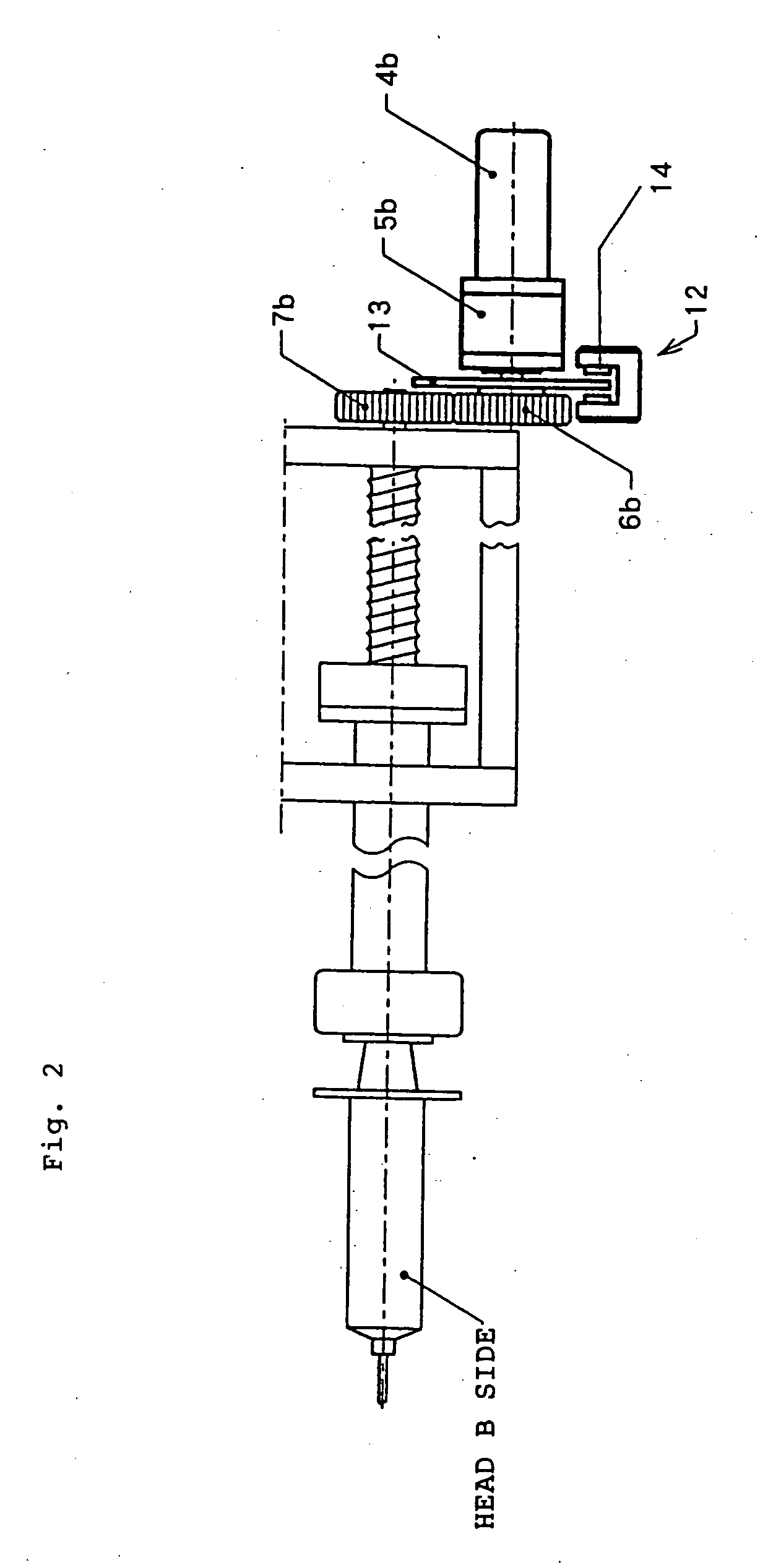

[0057] An example using a disc brake as backward-moving prohibition mechanism will be described below with reference to FIG. 2.

[0058] The disc brake 12 has a disc 13 and pads 14, which stops the rotation of the disc by holding the disc 13 between the pads 14. When the piston syringe at the head B is moved forward and backward, the space between the disc 13 and the pads 14 is left open so that the motor gear 6b can freely rotate. When the backward-moving of the syringe piston at the head B is desired to be prohibited, the disc 13 may be clamped by the pads 14 by electrically controlling the disc brake.

[0059] In this example, though the disc 13 is fixed to the motor gear 6b, it may be fixed to the screw gear 7b or fixed to any place of the axis of rotation.

[0060] In the above-described embodiments 1 and 2, though a method of using the brake was described, other types of brakes other than the electromagnetic brake and the disc brake may be used if the movement in the backward direct...

embodiment 3

[0061] An example using a ratchet mechanism as the backward-moving prohibition mechanism will be described below with reference to FIG. 3.

[0062] As shown in FIG. 3(a), a ratchet 15 is provided on a cylinder portion 19 of a ball nut unit 9b and fitted into a ratchet claw of a ratchet pole 16, making it possible to move forward the syringe piston and prohibit the backward-moving thereof. That is, when at least the motor at the side of the head B is stopped and the ratchet is allowed to engage with the ratchet claw, there is no backward-moving of the syringe piston nor a backward flow. When the syringe piston allows to move backward, a rotary solenoid 17 is electrically controlled so as to rotate the ratchet pole 16, and the engagement of the ratchet and the ratchet claw is released. In FIG. 3(b) (cross-sectional view at line A-A in FIG. 3(a)), a state of the ratchet being engaged with the ratchet claw and a physical relationship of the rotary solenoid 17 are shown.

[0063] The place w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com