Patterned layer for absorbent article

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

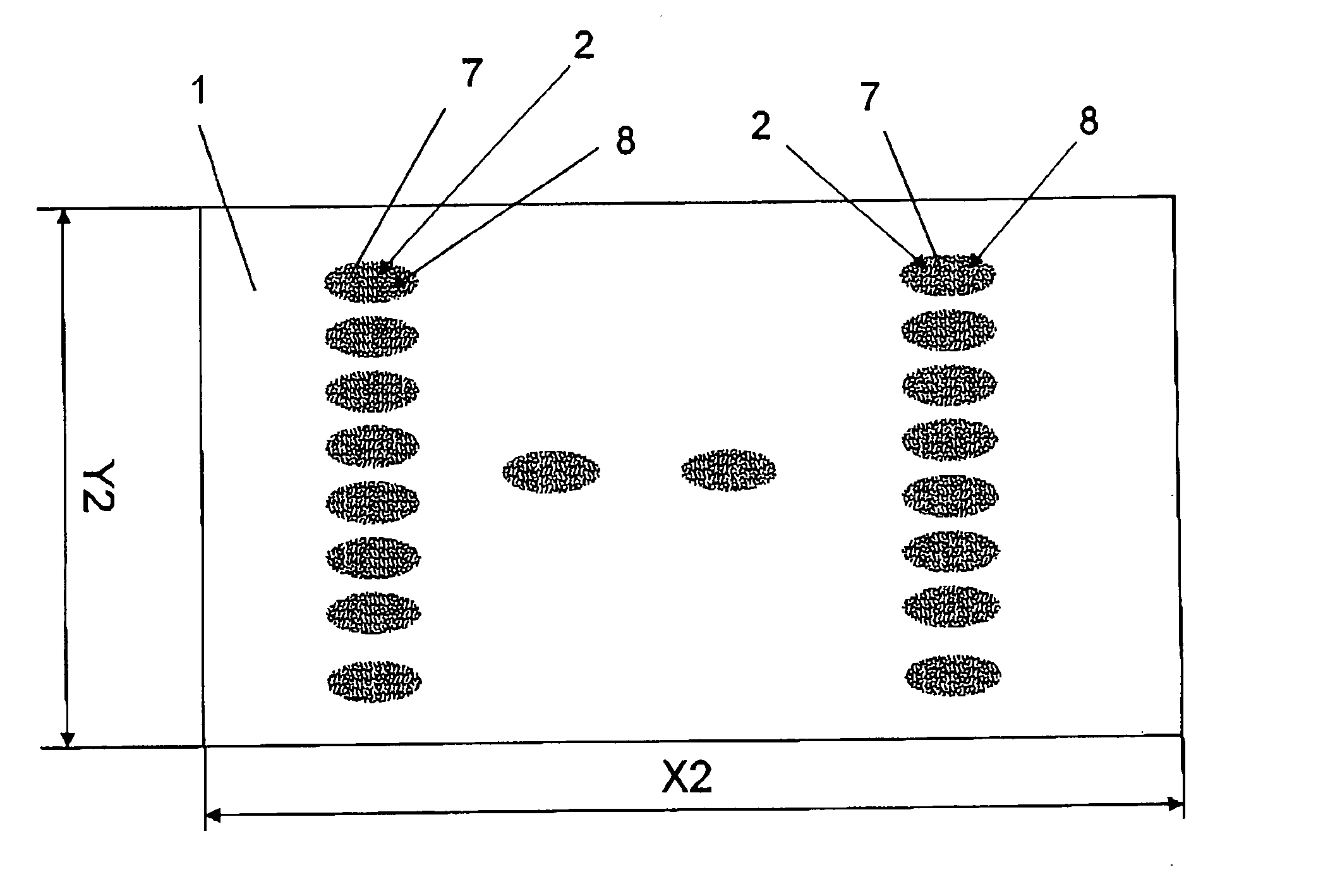

[0034]FIG. 1 shows a first embodiment where a patterned layer 1 with a length X1 (X direction) and a width Y1 (Y direction) is in a first state. Here, the pattern consists of a number of separate black dots 9 which together form the letter H. In FIG. 1, the layer 1 is in a drawn-together state where the layer 1 has puckered. FIG. 1 therefore shows the layer 1 in a puckered first state. The fact of the layer being puckered is marked in FIG. 1 by a wave-shaped pattern 3. The layer can be puckered in the X direction, the Y direction or both the X direction and the Y direction. The puckered layer 1 comprises elevations and depressions therebetween. In FIG. 1, the dots 9 have been formed by dye having been applied at points to the layer in such a way that a number of the wave-shaped elevations have been dyed when the layer 1 is in the puckered state. This will be explained in greater detail in connection with FIG. 2.

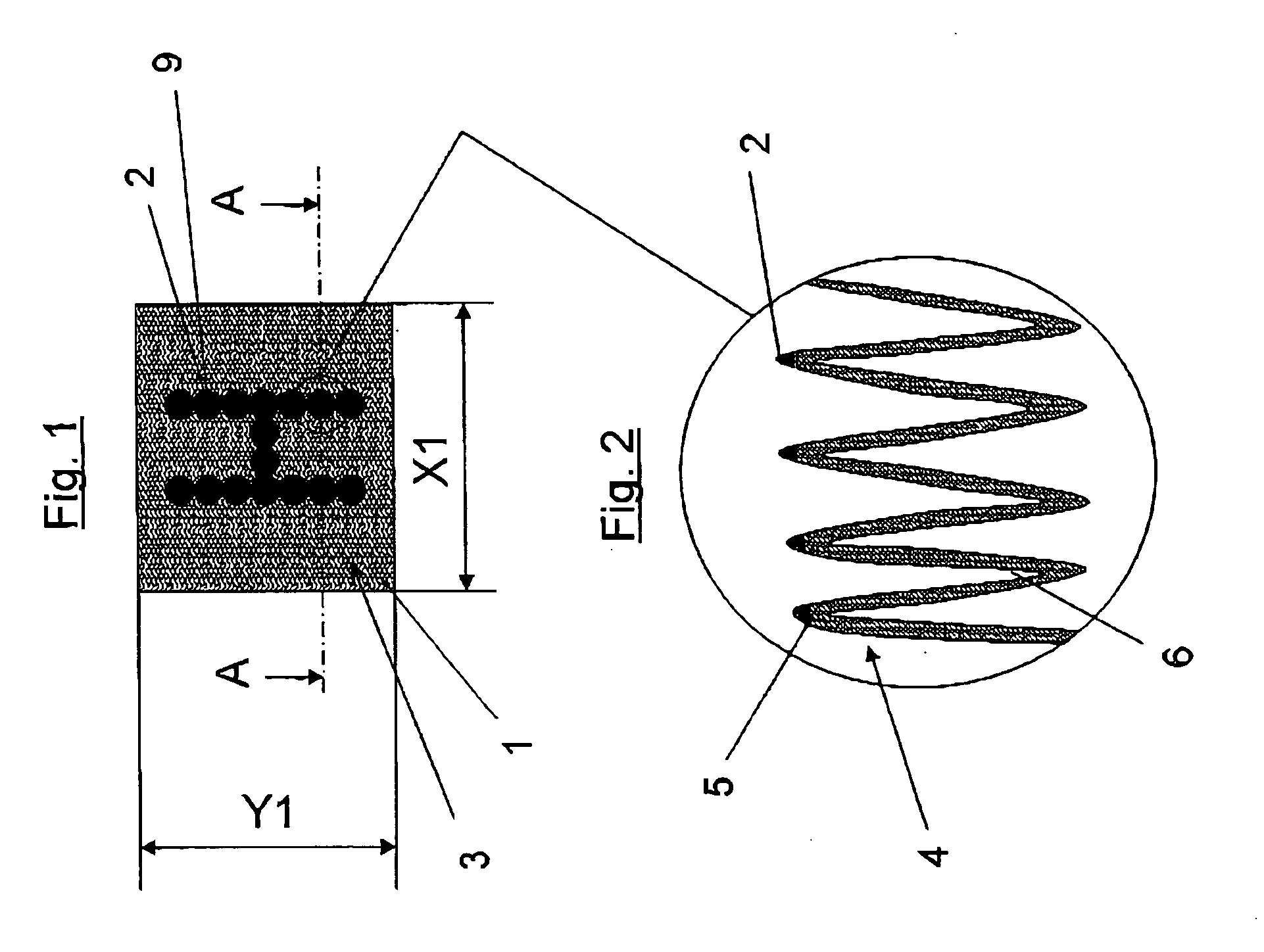

[0035]FIG. 2 shows an enlarged portion of a part of the layer 1 accordin...

second embodiment

[0039]FIG. 4 shows a second embodiment where the dye is applied at points to a layer 1 which is in the second state, that is to say in an expanded state where the layer has the length X2 and the width Y2. The dye is applied in the form of separate dots 9. In the second state, the dots 9 are located at such a spacing from one another than the pattern H is perceived by an observer as diffuse and unclear. FIG. 4 shows moreover that the layer has been stamped with impressions 10 in the form of a punctiform pattern, where only a number of the punctiform impressions 10 have been dyed to form the dots 9. The punctiform impressions 10 can constitute a three-dimensional pattern in a layer but can also constitute bonding points between two layers. The punctiform impressions 10 can be brought about by, for example, one or more layers being guided between a stamping roller and an opposite ultrasound device or an opposite counterstay roller. PCT SE03 / 01959 indicates an advantageous method of int...

third embodiment

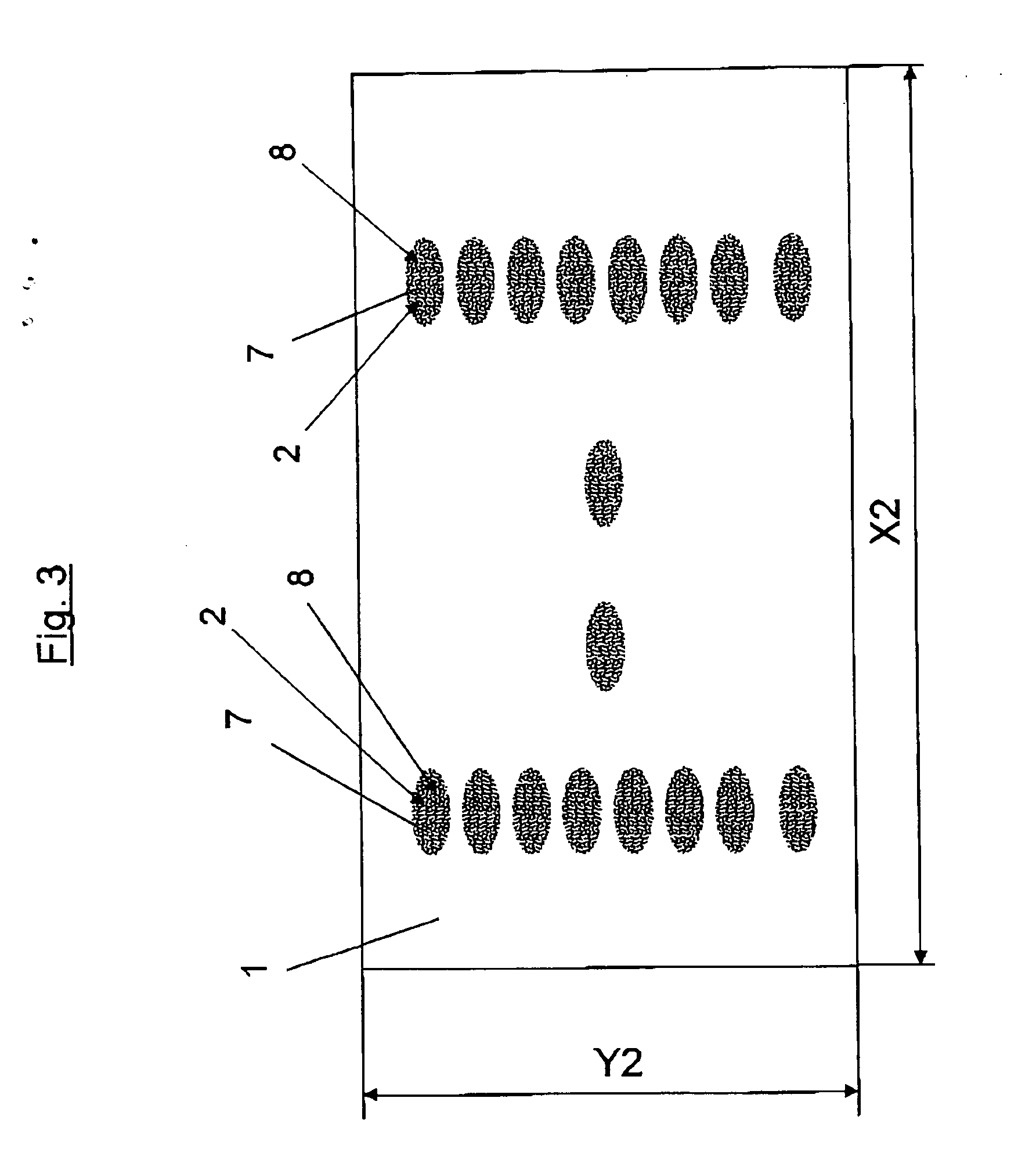

[0043]FIG. 7 shows a third embodiment where the dye is applied at points to a plane or smooth layer 1 which is in the first state, that is to say in a contracted state where the layer 1 has the length X1 and the width Y1. The dye is applied in the form of separate dots 9. In the first state, the pattern H appears clearly for an observer on account of the fact that the spacing between the dots 9 is so small that, for an observer, the dots come together to form the pattern H. FIG. 7 shows that the layer 1, like the layer in FIG. 4, has been stamped with impressions 10 in the form of a punctiform pattern, where only a number of the punctiform impressions 10 have been dyed. Here too, the punctiform impressions 10 can constitute a three-dimensional pattern in a layer but can also constitute bonding points between two layers.

[0044]FIG. 8 shows a layer 1 according to FIG. 7 in the second state, that is to say when the layer has the length X2 and the width Y2. In the second state, the dots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com