Fuel reforming apparatus

a technology of fuel reforming apparatus and fuel mixture, which is applied in the direction of combustion air/fuel air treatment, machines/engines, gaseous fuels, etc., can solve the problems of difficult to allow the reforming reaction in the reforming reaction chamber to proceed, and the concentration of mixture flowing into the reforming reaction chamber becomes non-uniform, so as to achieve high reforming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, a preferred embodiment of the invention will be described with reference to the accompanying drawings.

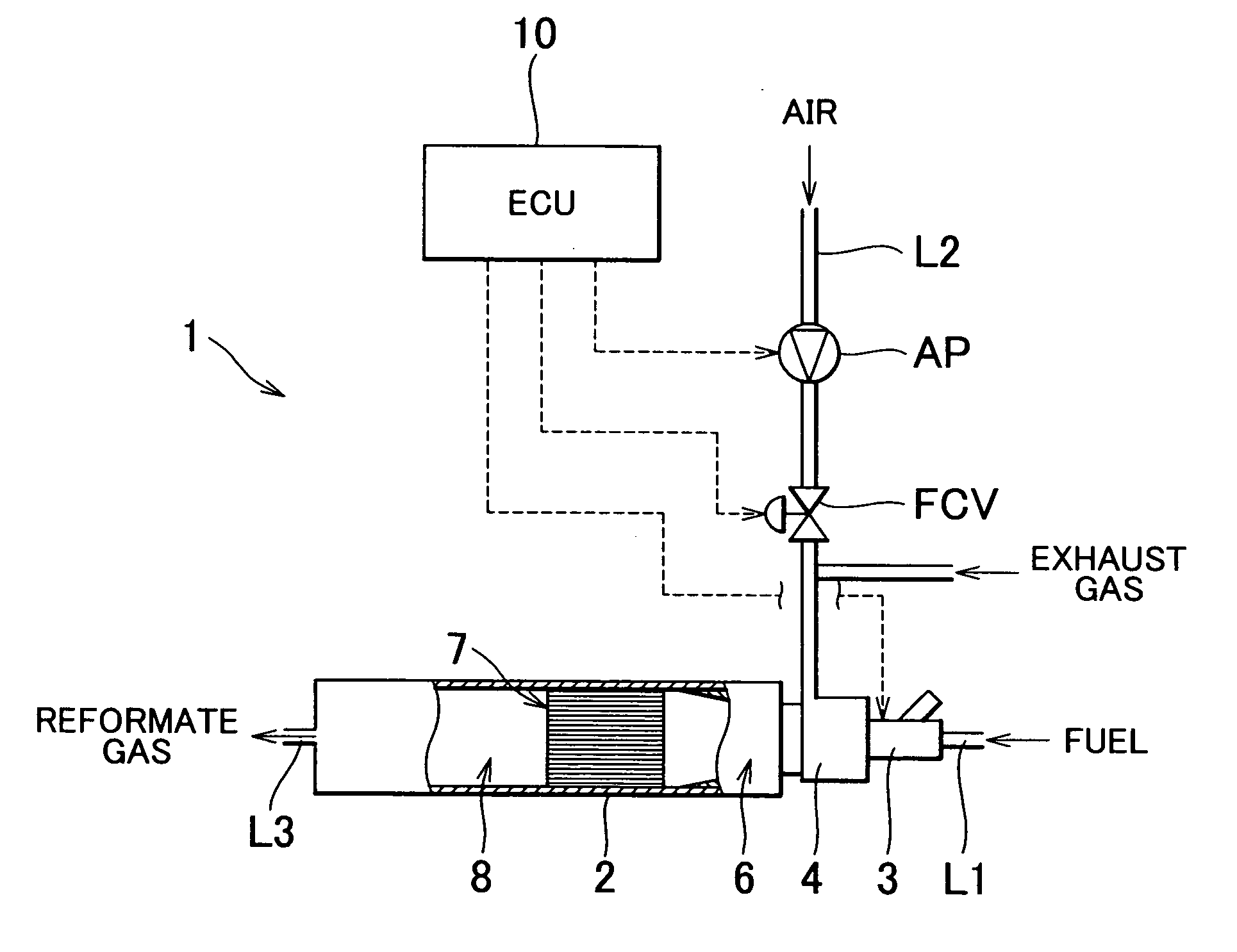

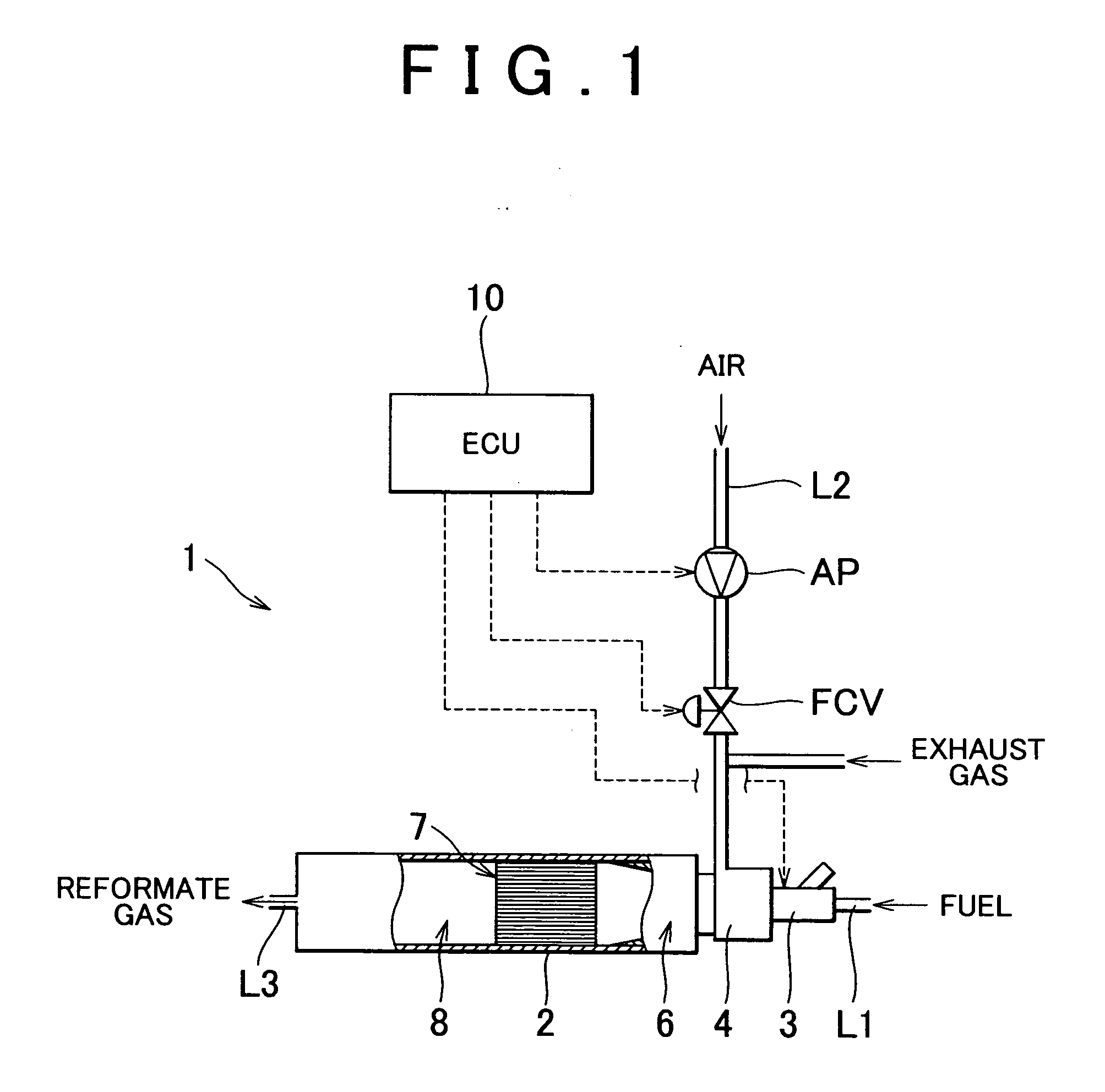

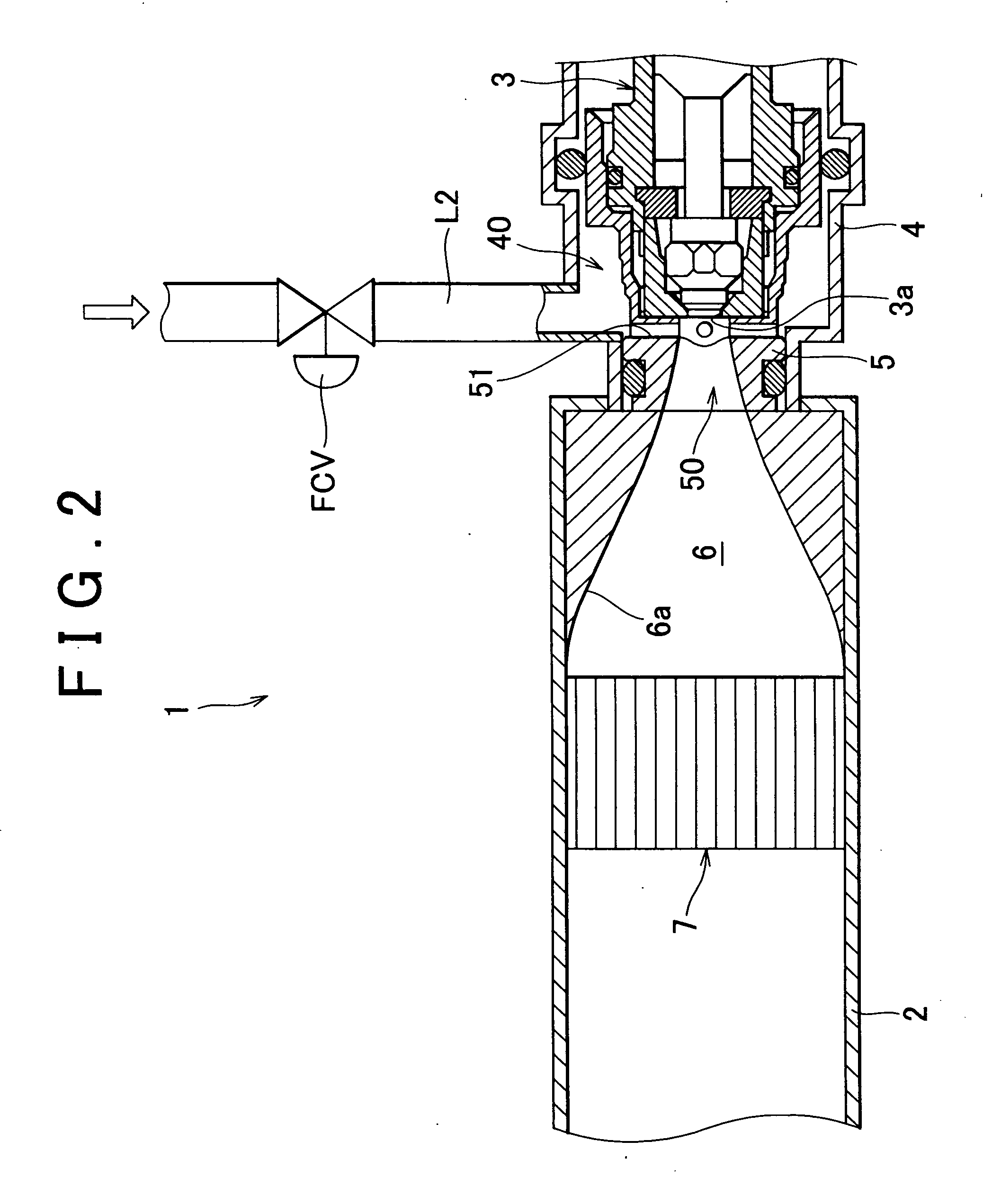

[0018]FIG. 1 is a schematic diagram showing a configuration of a fuel reforming apparatus according to an embodiment of the invention. A fuel reforming apparatus 1 shown in FIG. 1 can reform a mixture of air and hydrocarbon fuel such as gasoline. For example, the fuel reforming apparatus 1 is used for generating fuel (reformate gas) for an internal combustion engine that is a driving source of an automobile. As shown in FIG. 1, the fuel reforming apparatus 1 includes a main body 2 that is formed to have a generally cylindrical shape, and an injector (fuel supply means) 3 connected to an end portion of the main body 2 (an end portion on the right side in FIG. 1).

[0019] The injector 3 is connected to a fuel tank (not shown) via a fuel supply pipe L1 and a fuel pump (not shown). When the fuel reforming apparatus 1 is used, the injector 3 injects hydrocarbon fuel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com