Multi-layer coaxial vaso-occlusive device

a vaso-occlusive device and coaxial technology, applied in the field of vaso-occlusive devices, can solve the problems of decreasing and achieve the effects of reducing the contact area, reducing the aggregate friction, and reducing the resistance to device manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

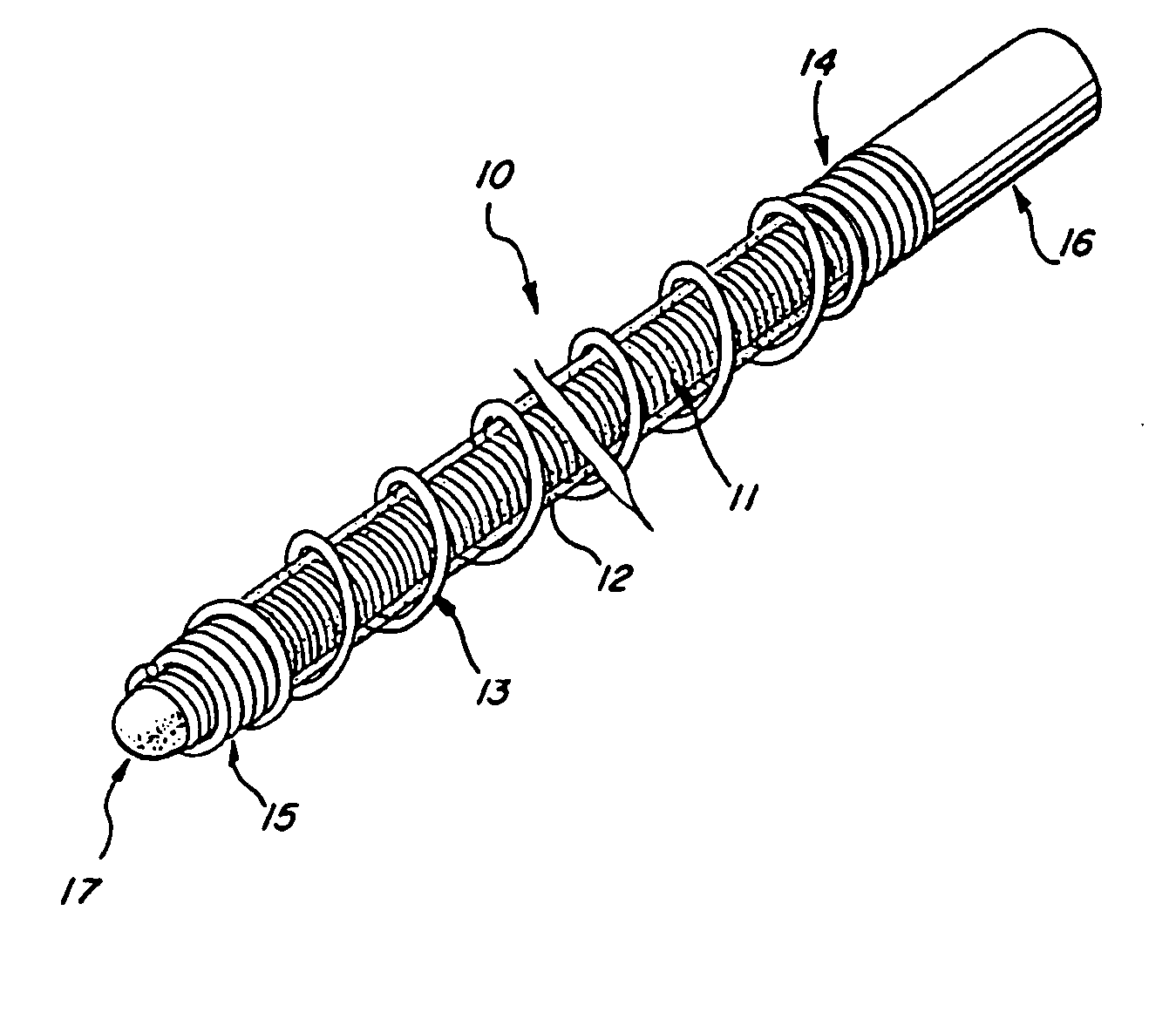

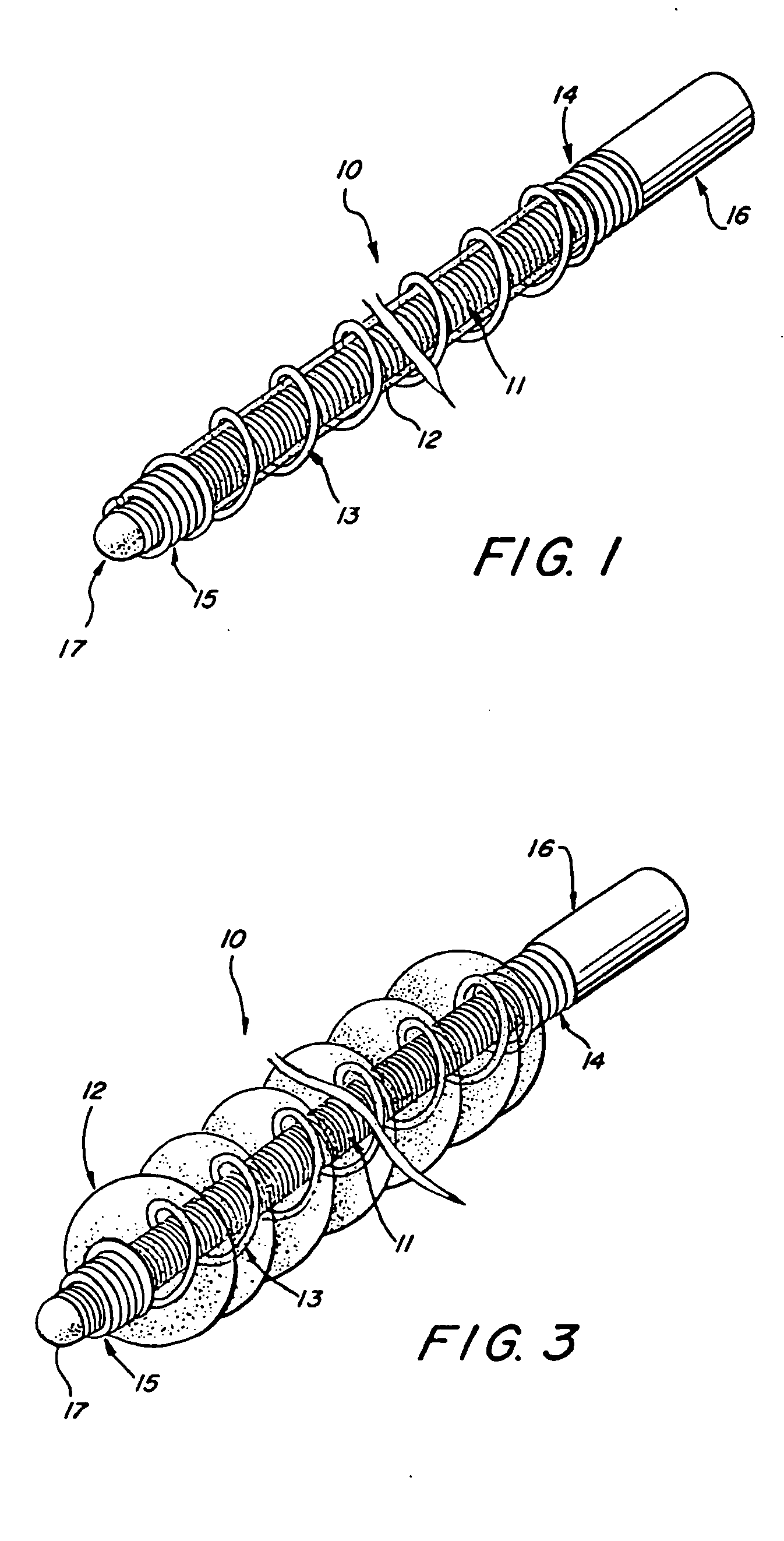

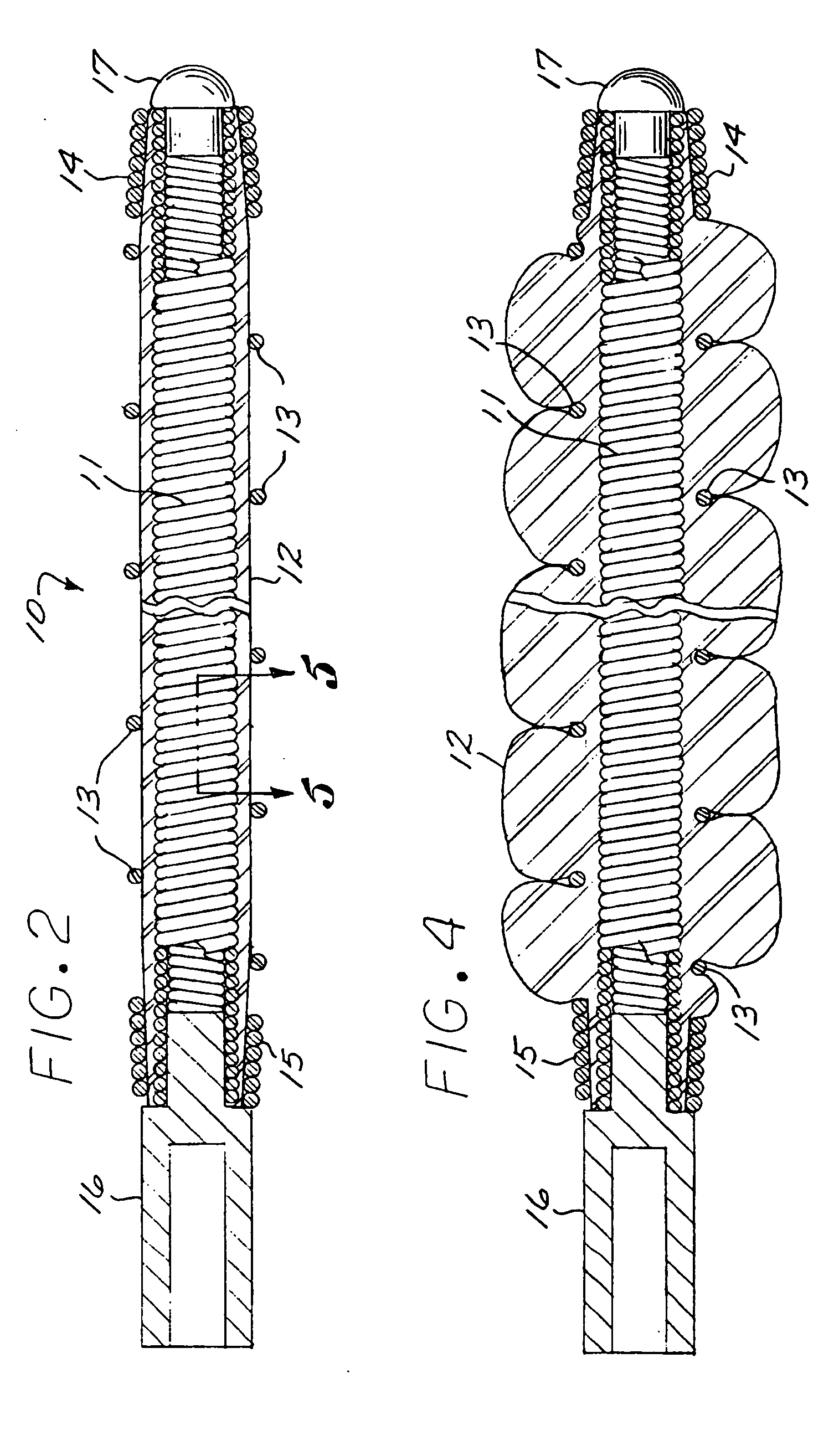

[0025] Referring to FIGS. 1-4, a vaso-occlusive device 10, in accordance with a preferred embodiment of the invention, comprises three elongate, coaxial elements: an inner element 11, a non-metallic intermediate element 12, and a non-expansile outer element 13 that covers at least a portion of the intermediate element. The intermediate element 12 is in intimate contact with both the inner element 11 and the outer element 13.

[0026] The inner element 11 is formed of a flexible, elongate filament or wire that is preferably made of a material that allows visualization under various medical imaging means, such as X-ray, MRI, or ultrasound. Preferably, the inner element 11 is formed from a length of wire made of any of various biocompatible, radiopaque metals, such as platinum, tantalum, tungsten, gold, titanium, nitinol, stainless steel, Elgiloy (cobalt-chromium-nickel), or other suitable alloys known in the art. Alternatively, it can be made from or include non-metallic materials, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com