Kitchen ventilation degreasing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

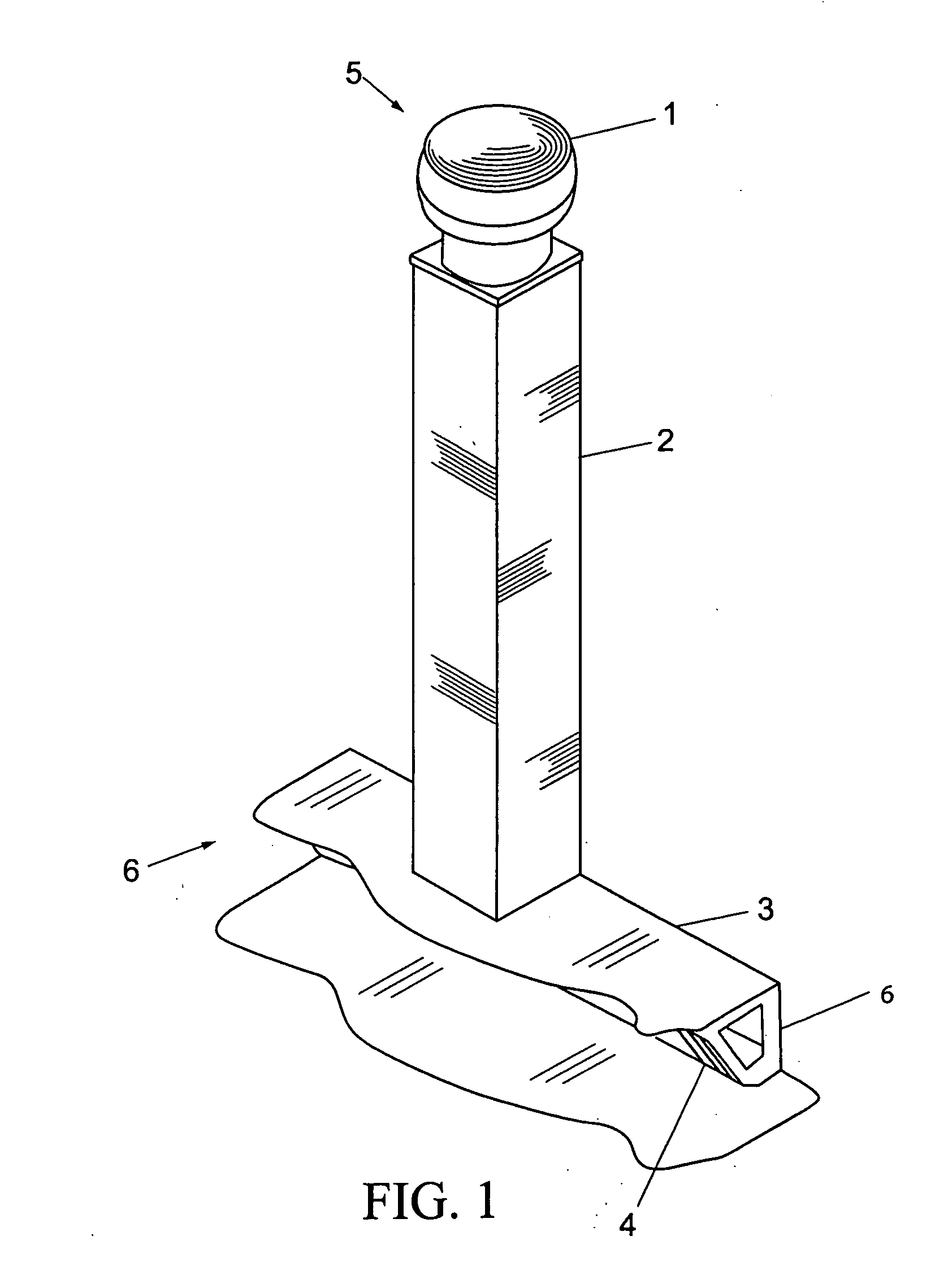

[0047] The present invention is described in the context of a conventional kitchen ventilation system with an exhaust end 5 and an air intake end 6 (FIG. 1), an electronically controlled exhaust fan 1 at exhaust end 5, a rectangular vertical duct 2, and a kitchen hood 3 with removable flue filters 4 at air intake end 6. In operation, the exhaust fan 1 pulls kitchen air (including smoke and airborne grease) into the hood 3 through flue filters 4, into the duct 2 and out exhaust fan 1. One skilled in the art should appreciate that the present invention can be easily adapted for use with any similar ventilation system, including systems using cylindrical or non-vertical ducting, without departing from the scope and spirit of the present invention.

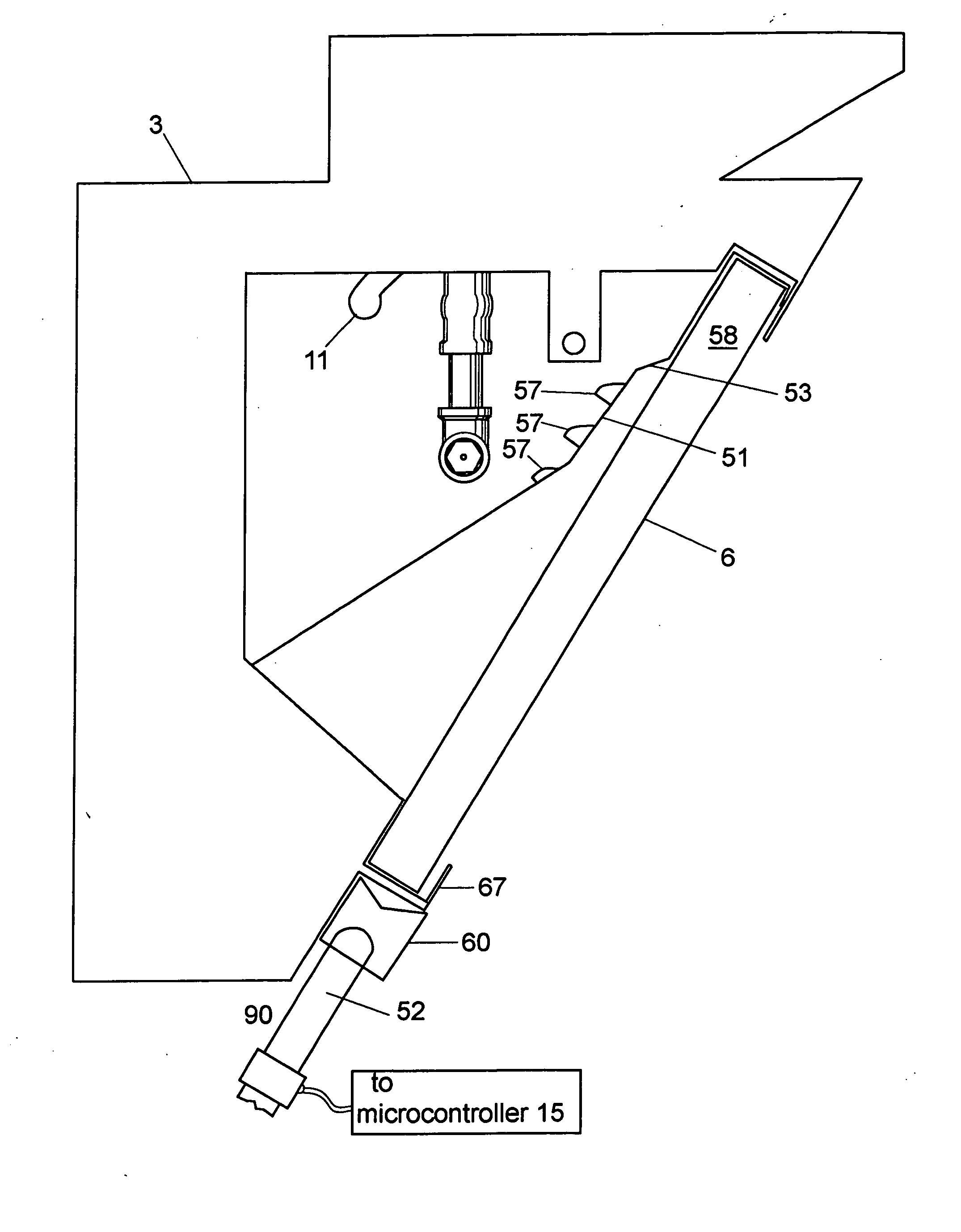

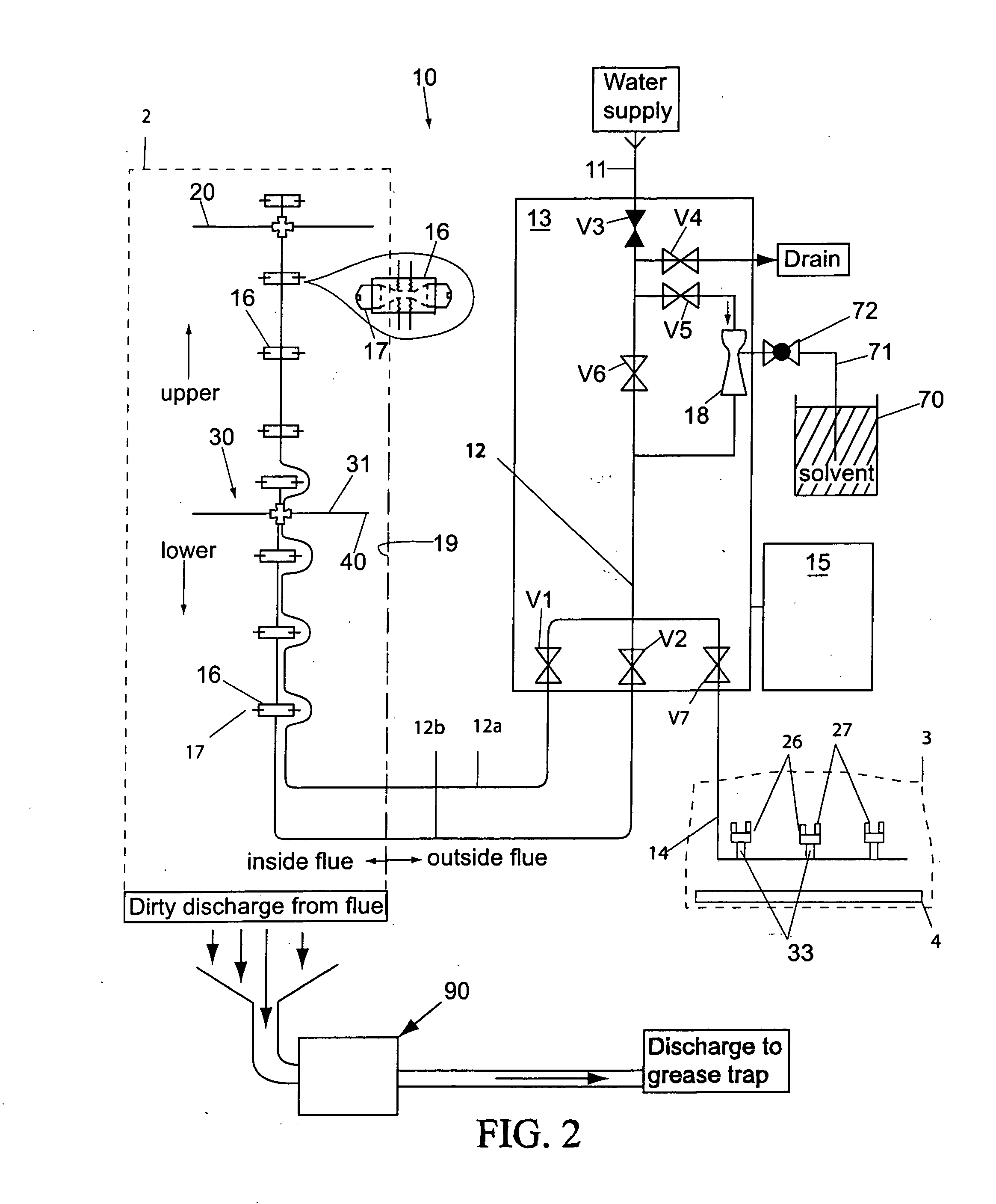

[0048] The kitchen ventilation degreasing system according to the present invention includes two main components, a cleaning mechanism 10 (described below with reference to FIGS. 2-14) with support features, and a drainage mechanism 50 (see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com