Mean pressure estimation for compressible fluid strut

a technology of compressible fluid and mean pressure, which is applied in the direction of shock absorbers, instruments, cycle equipment, etc., can solve the problems of delay in the updating step, and achieve the effect of eliminating cost-effective pressure sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

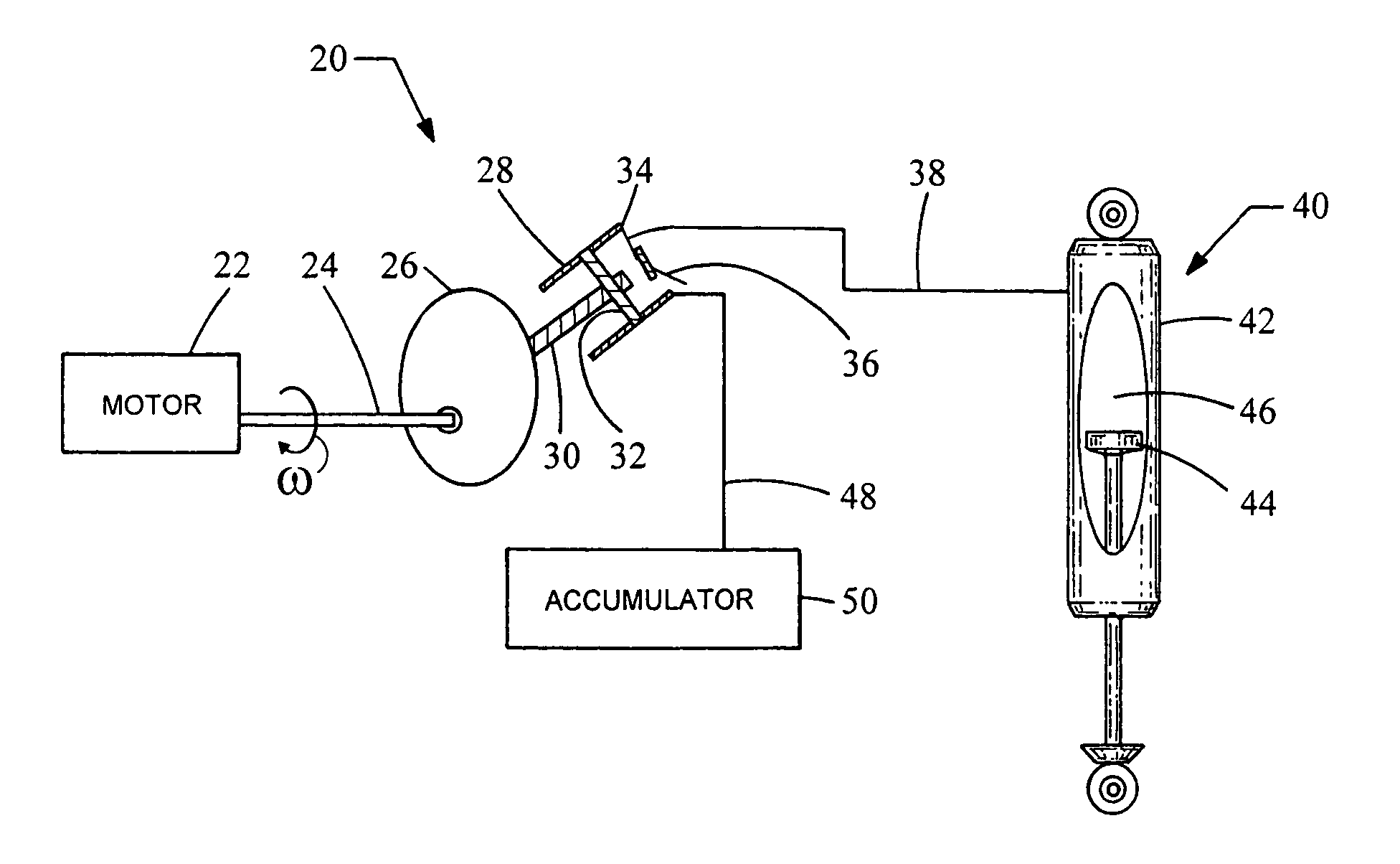

[0018] Turning now to the figures, FIG. 1 depicts a schematic illustration of an active suspension system 20 constructed in accordance with the teachings of the present invention. The active suspension system 20 includes, among other components not listed or shown here, a motor 22 driving a cylinder 28, which in turn supplies and returns pressurized fluid to a compressible fluid strut 40. The motor 22 is preferably a digital displacement pump motor which allows execution of discrete flow demands. The motor 22 includes a shaft 24 which in turn drives a crankshaft that 26 translates the rotational motion of the motor 22 and shaft 24 into an axial motion for driving the cylinder 28.

[0019] The cylinder 28 generally includes a piston rod 30 connected to a piston 32. The piston rod 30 is driven by the crankshaft 26, and the piston 32 reciprocates within the cylinder 28 to pressurize fluid contained therein. The cylinder 28 includes a high pressure valve 34 and a low pressure valve 36. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com