Method and system for measuring partial discharge

a partial discharge and measurement method technology, applied in the field of partial discharge measurement methods and systems, can solve the problem of difficult detection of accurate partial discharge signal patterns, and achieve the effect of accurately measuring phase shifts and accurate compensating phase shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

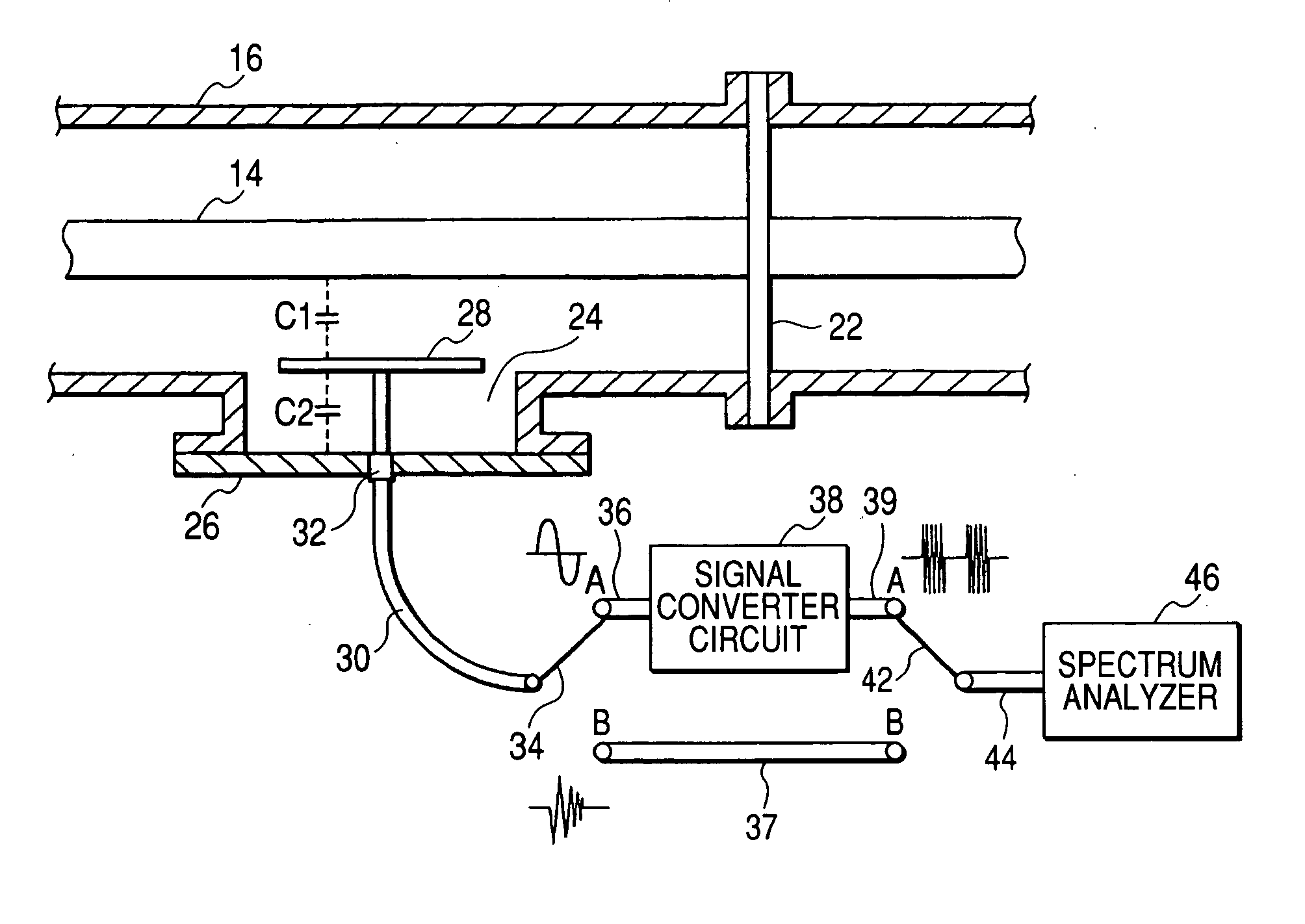

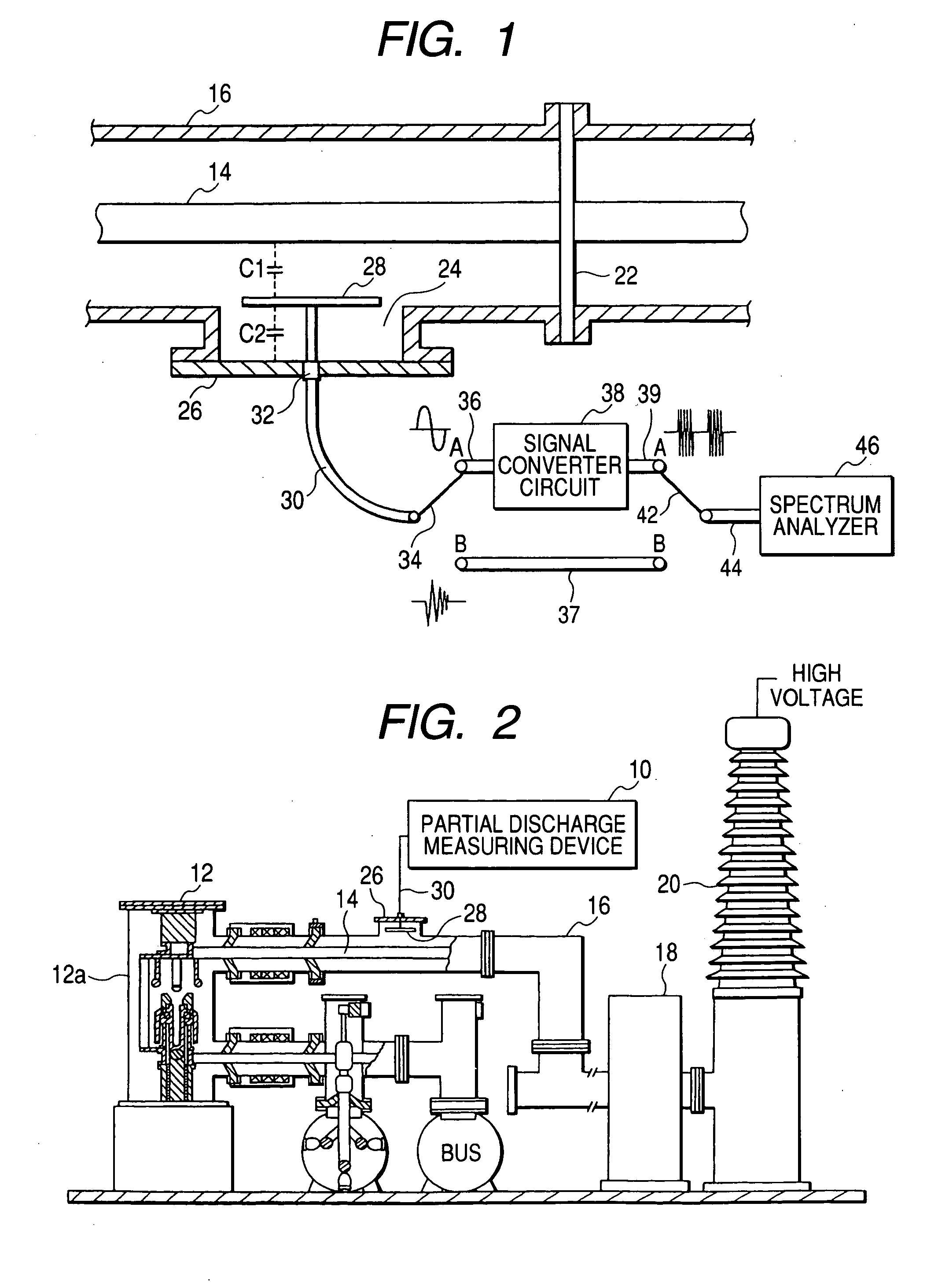

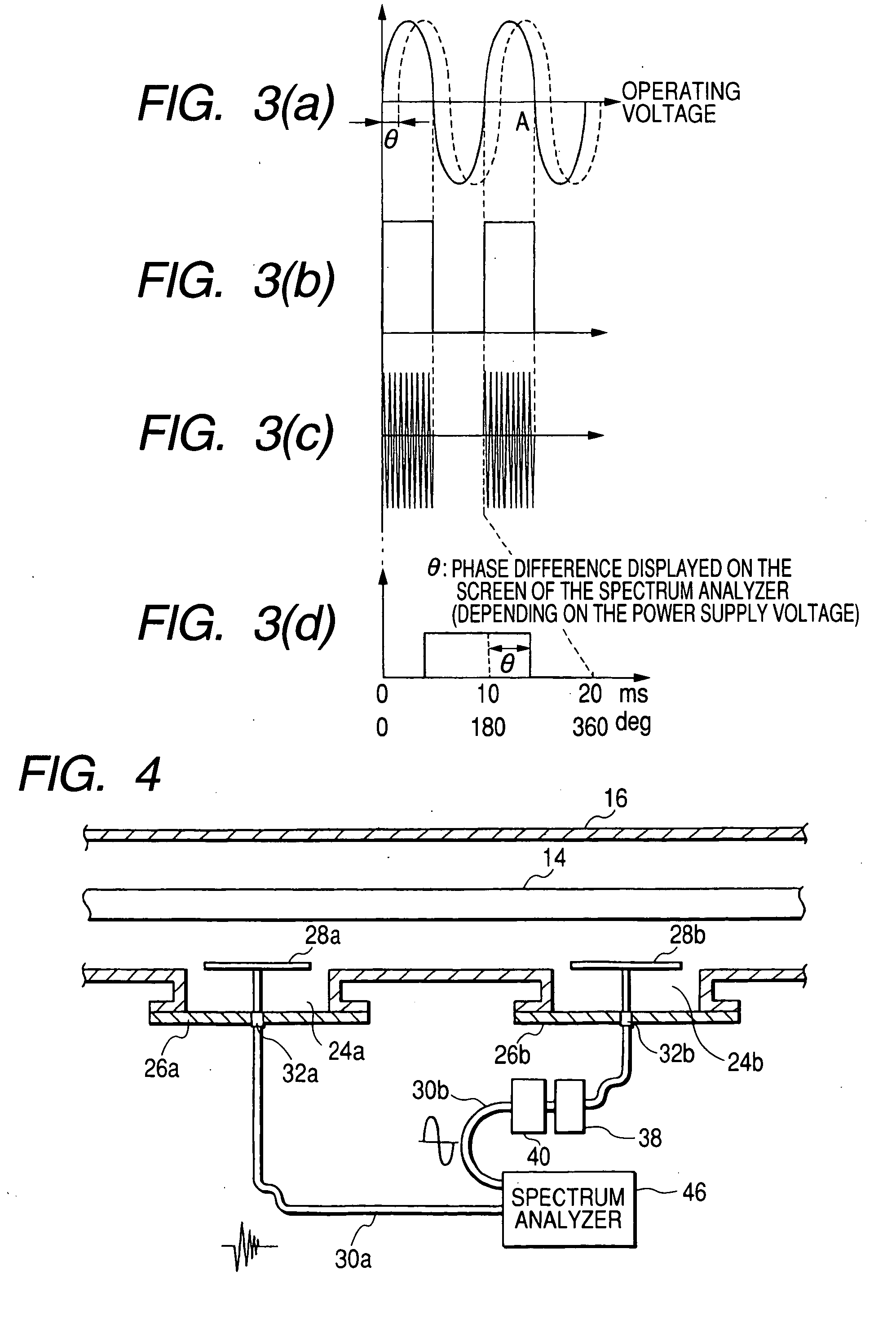

[0016] Hereafter, an embodiment of the present invention will be explained with reference to the drawings. FIG. 1 is a block diagram of a partial discharge measuring device according to the present invention, and FIG. 2 is a side cross-sectional view of the major portion when the partial discharge measuring device is installed in an gas insulated device.

[0017] In FIGS. 1 and 2, the partial discharge measuring device 10 is installed in the vicinity of the metal container 16, which encases a high-voltage conductor 14 and an insulation material, so as to measure one phase of the high-voltage conductor 14 which is a gas insulated bus connected to a gas circuit breaker 12. One end of the high-voltage conductor 14 is connected to an electrode of the gas circuit breaker 12, and the other end is exposed to the atmosphere via an arrester 18 and a bushing 20. For example, 60,000 to 500,000 volt alternating voltage is applied to the high-voltage conductor 14 as an operating voltage. The high-v...

second embodiment

[0027] Next, the present invention will be explained with reference to FIG. 4. In this embodiment, antennas 28a and 28b which have the same function as an antenna 28 are encased in hand holes 24a and 24b, respectively, and each antenna 28a and 28b is connected to a spectrum analyzer 46 via a coaxial cable 30a or 30b, and a signal converter circuit 38 and a delay circuit 40 are inserted in the middle of the coaxial cable 30b. The other configuration is the same as that shown in FIG. 1. To equalize the propagation time of each signal that is transmitted through coaxial cables 30a and 30b, the lengths of the coaxial cables 30a and 30b are the same.

[0028] The antenna 28a functions as a voltage sensor to detect partial discharge, and the antenna 28b functions as a voltage sensor to detect an operating voltage applied to the high-voltage conductor 14. The operating voltage signal detected by the antenna 28b is formed into a waveform by a signal converter circuit 38, and delayed by the del...

third embodiment

[0030] Next, the present invention will be explained with reference to FIG. 5. In this embodiment, instead of using an antenna 28b as a voltage sensor, an electromagnetic wave sensor 50 which is disposed around the insulating support medium 22 and detects an operating voltage applied to the high-voltage conductor 14 is used, and instead of using a spectrum analyzer 46, an oscilloscope 52 is used. The other configuration is the same as that shown in FIG. 4. This embodiment uses an oscilloscope 52 as a measuring instrument which displays input information on its screen. Accordingly, a coaxial cable 30a is connected to a measurement signal input terminal of the oscilloscope 52, and a coaxial cable 30b is connected to a trigger signal input terminal of the oscilloscope 52.

[0031] In this embodiment, the operating voltage signal detected by an electromagnetic wave sensor 50 functions as a trigger, and partial discharge signals detected by an antenna 28a are sequentially displayed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com