Shock absorbing rope

a technology of shock absorption and rope, which is applied in the direction of safety belts, gymnastic exercise, braids, etc., can solve the problems of jumping phenomenon, application of intense reaction force to workers, and defect of conventional woven webbing 100/b>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

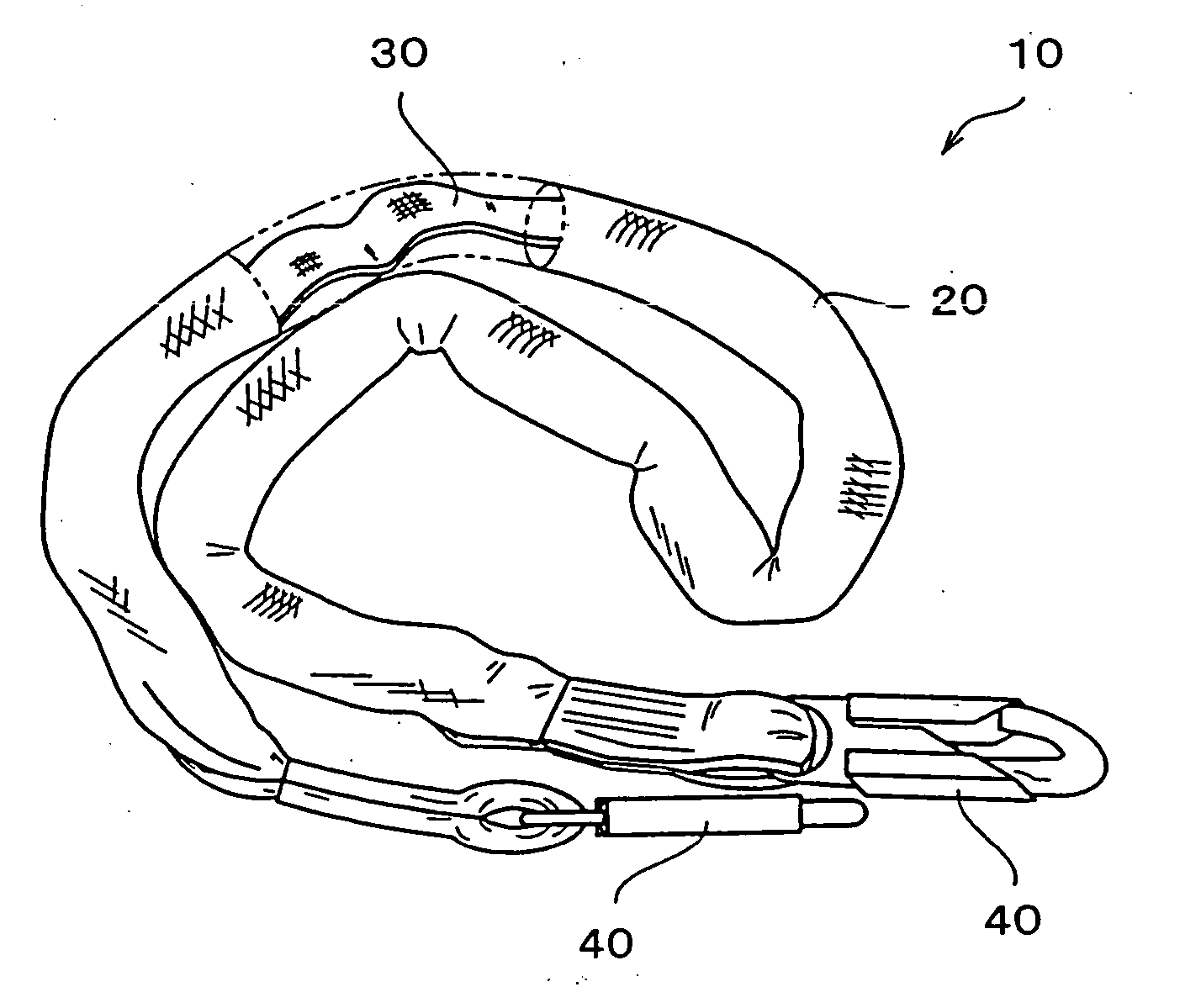

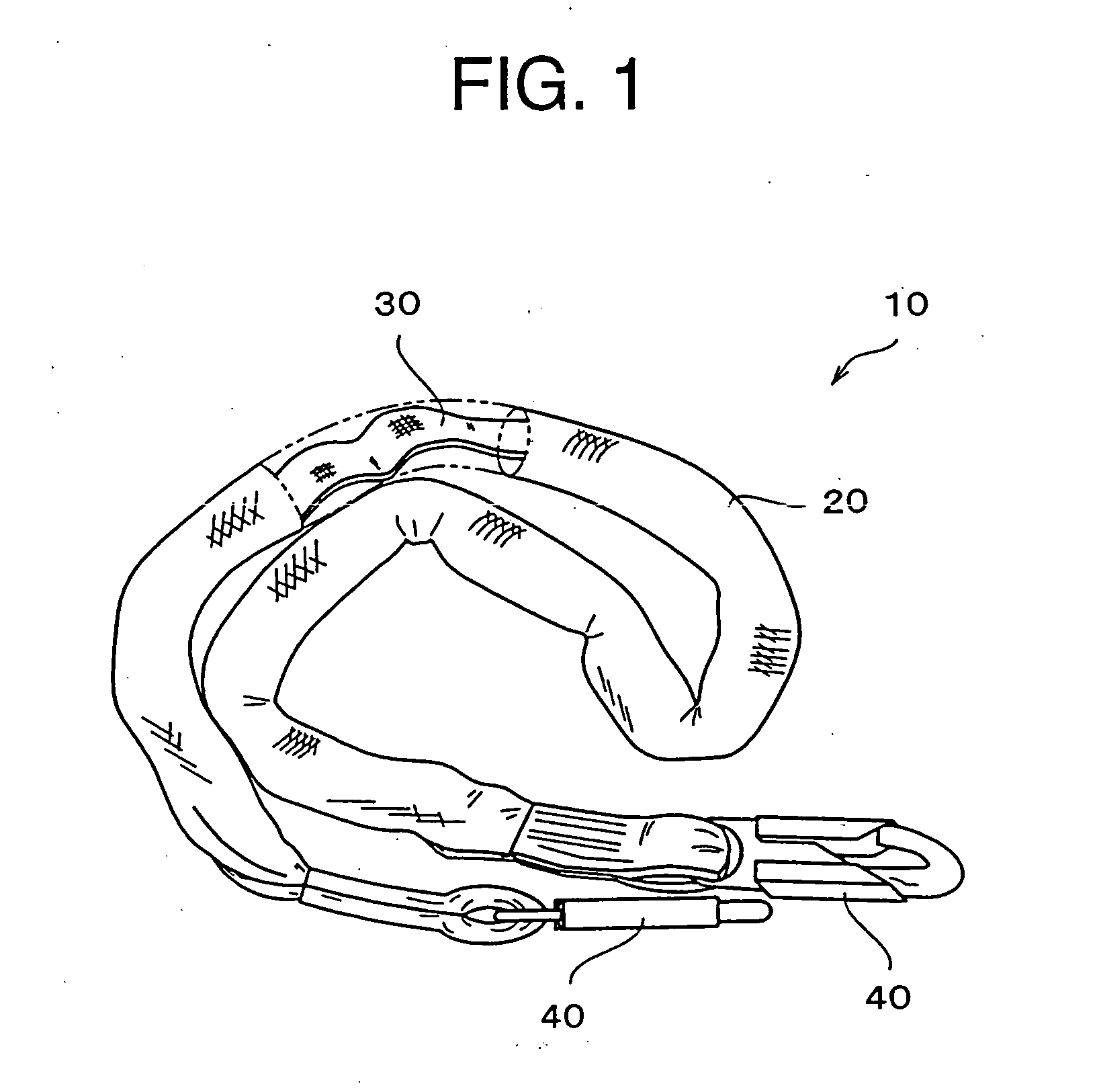

[0051] In FIG. 1, a reference numeral 10 is a pattern diagram showing a shock absorbing rope that is used as a safety member for working at the high working site having connecting fittings 40 that are fixed to the both ends of the shock absorbing rope in the longitudinal direction thereof, respectively. According to the illustrated example, a shock absorbing rope 10 forms a rope body 20 shaped in a flat and long tube and a core member 30 shaped in a narrow tape arranged inside of the rope body 20 in an eased state independently and separately from each other.

[0052] The rope body 20 is formed in a tubular hollow weaving having the core member 30 inserted through it. The both ends of the rope body 20 and the core member 30 in the longitudinal direction thereof are wrapped by the adhesive tape and the like to be formed in a taper while being elongated narrowly. The both ends of the rope body 20 and the core member 30 in the longitudinal direction thereof are folded s...

second embodiment

(Second Embodiment)

[0073]FIG. 5 a pattern diagram showing other example of the shock absorbing rope 10 according to the present invention. In the meantime, the same member names and the same reference numerals are given to the substantially same members as those in the first embodiment. Accordingly, the detailed description of these members will not be repeated here.

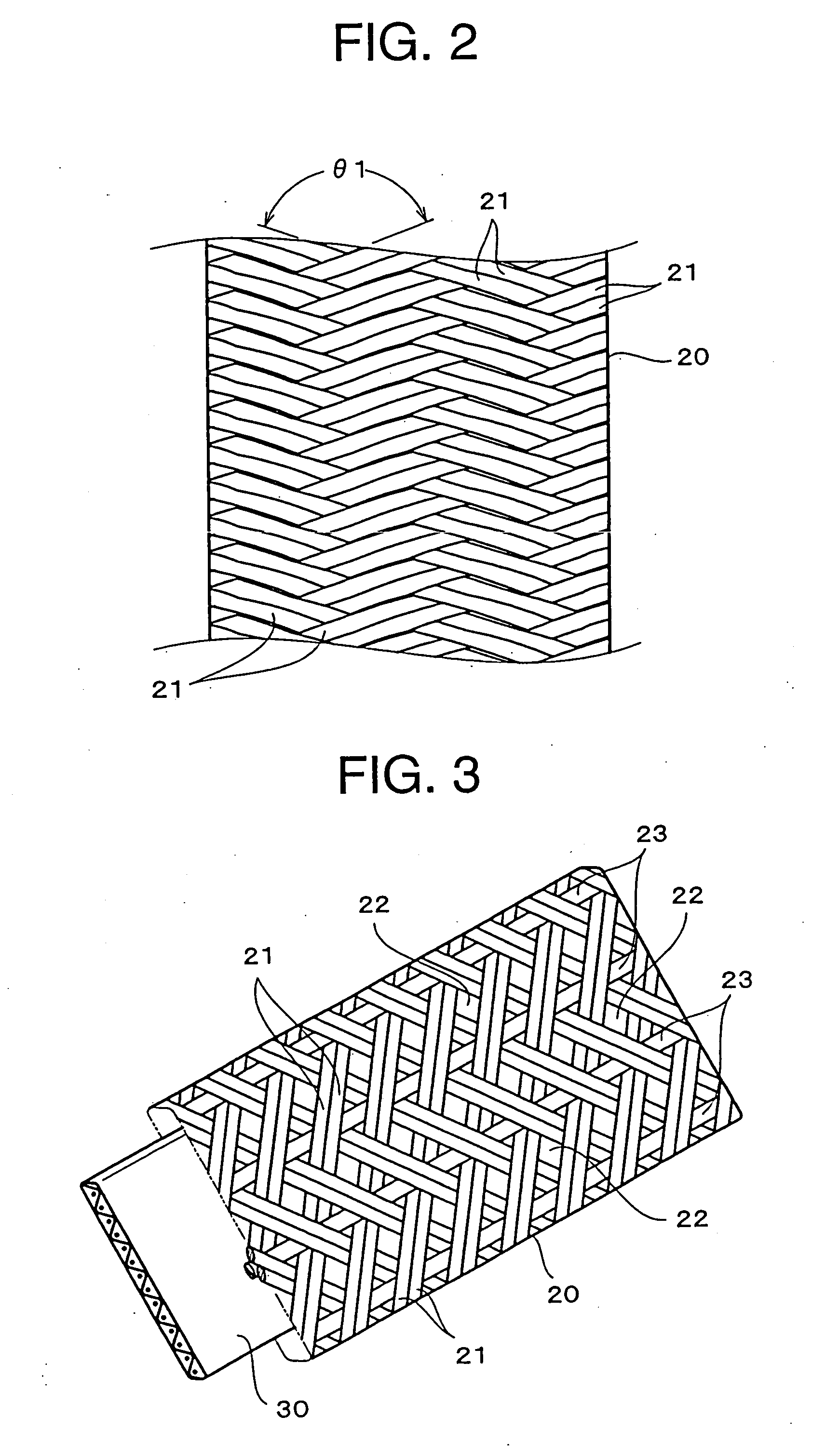

[0074] In this drawing, a basic configuration of the shock absorbing rope 10 is made of a general hollow woven fabric having two elastic rubbers 23 inserted on the front and rear surfaces of a long tubular rope body 20. The rope body 20 can be formed as a long tubular body by horizontally putting a weft thread row 24 into a warp thread row 21 of a synthetic fiber made of a resin material such as a polypropylene fiber, a polyester fiber, and a nylon fiber having a high intension and a high durability.

[0075] The elastic rubber 23 can be woven as a partial warp thread of the hollow woven part when weaving the rope body 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com