Packaging device and method

a packaging device and packaging technology, applied in the field of packaging devices and methods, can solve the problems of reducing the profitability of a company, not ensuring the item, and a significant cost of packaging an article, so as to achieve less waste, less raw materials, and less cost of manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

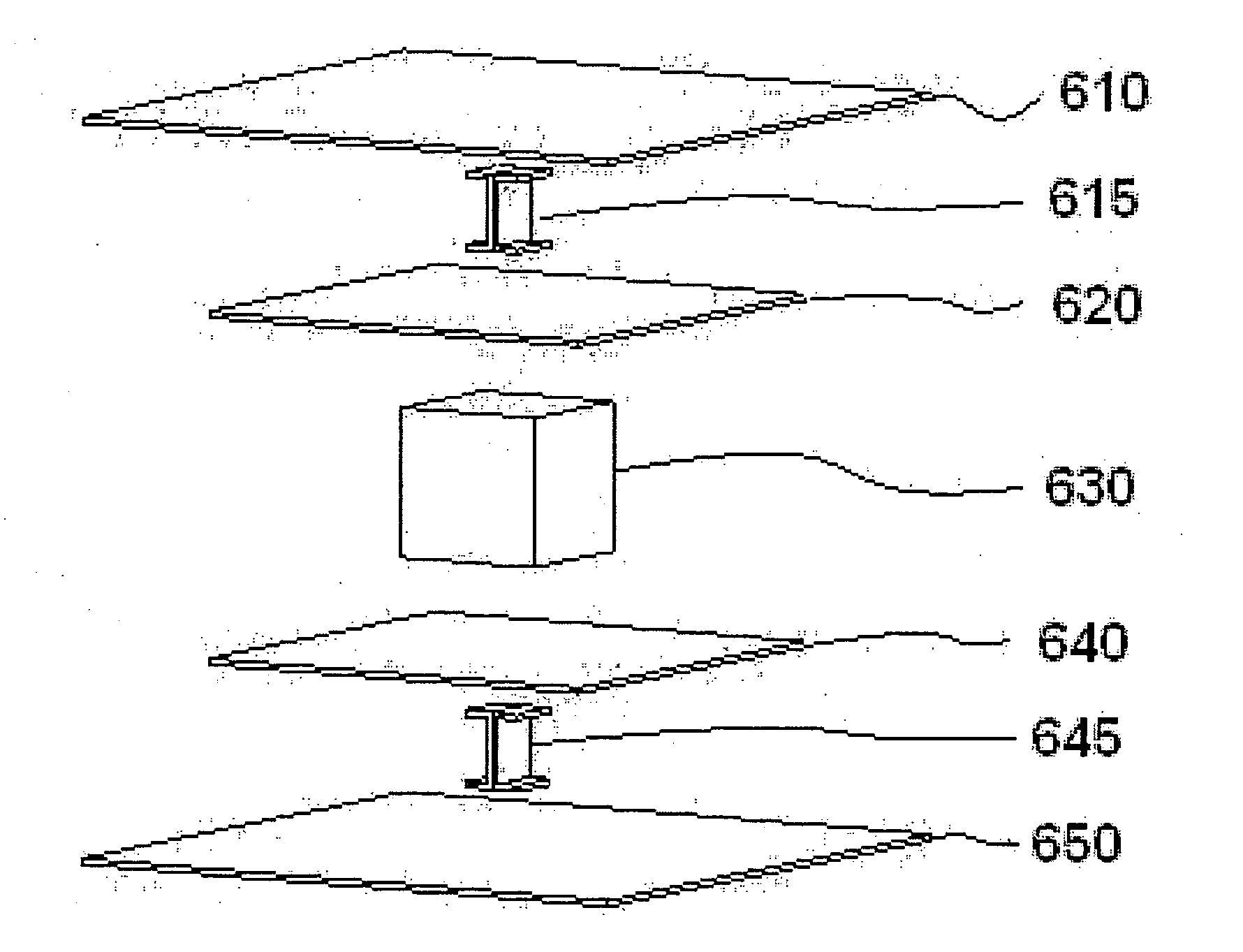

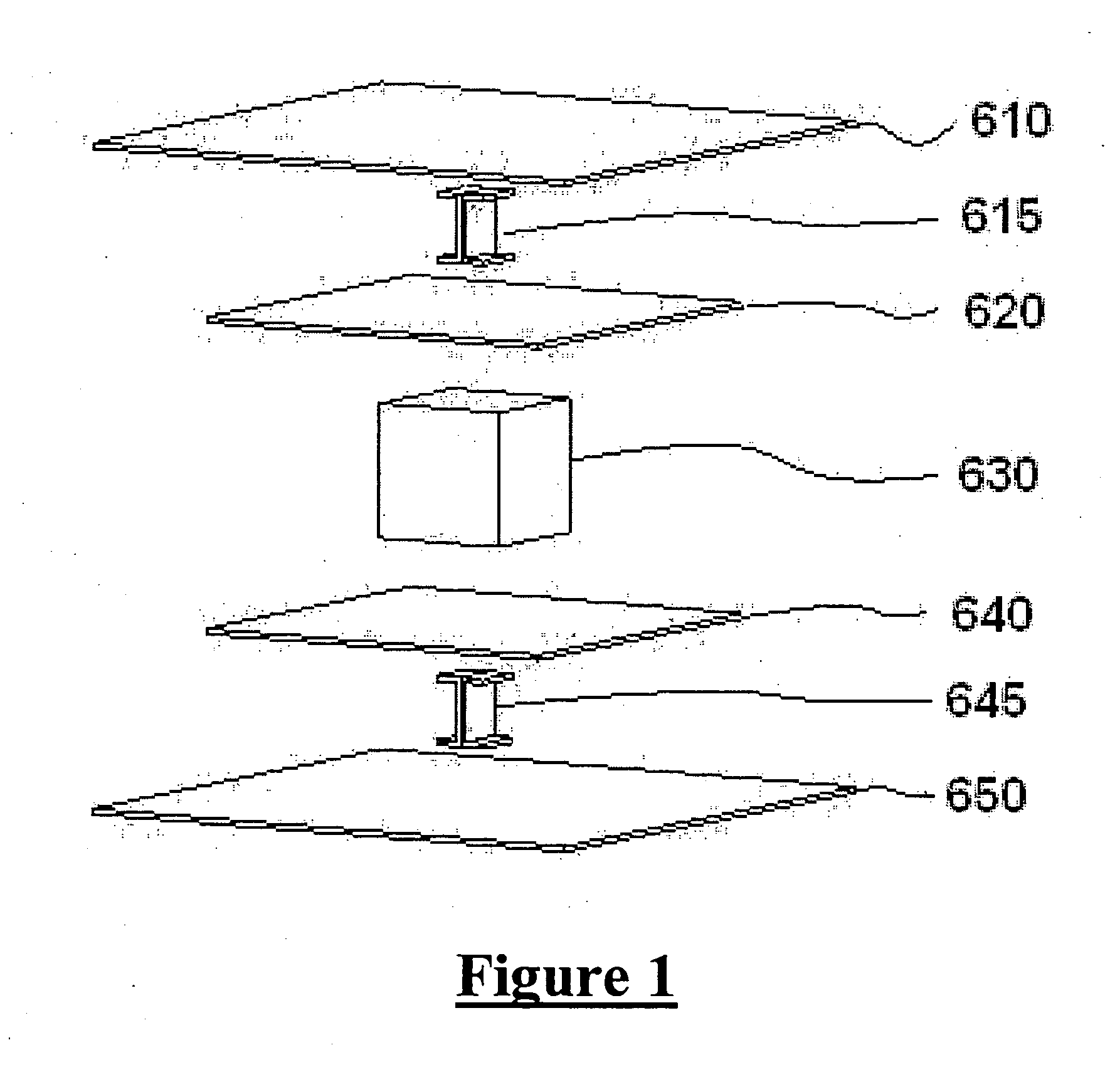

[0095]FIG. 1 is a perspective exploded view of a packaging device, generally designated as 600, according to the present invention, and FIG. 2 is a front exploded view thereof. Referring to FIGS. 1 and 2, the device 600 includes a number of component layers and linkages for securely a package article 630. The article 630 may not form part of the invention itself, but is shown for purpose of illustration as to how the invention may secure the article 630. Alternatively, the article 630 may itself be a box or package according to the present invention, with the item to be shipped placed within. As noted above, the article 630 may comprise another packaging system of the present invention, packaged within the system of the present invention.

[0096] The packaging device 600 includes an upper outer layer 610 and a lower outer layer 650, which may be formed of any type of elastomeric or resinous material, or a rigid material. In the embodiment as shown in FIGS. 1 and 2, the upper outer lay...

second embodiment

[0111]FIG. 8 is a perspective exploded view of the present invention. To simplify this exploded drawing, the linkage assemblies linking the center of the outer layers and the wrapping layers have been omitted. As noted above, the flexible linkages may be in tension, as to the flanges formed by the wrapping layer that also act as linkages. In order to achieve this requirement, wrapping layers 420 and 440 may be smaller than outer layers 410 and 450.

[0112] To overcome the size difference of the heat sealing parts, and to facilitate the heat sealing operation, a fixture comprising upper and lower portions 400 and 460 may be adopted to hold the center portion of the outer layers 410 and 450 at a certain distance from the wrapping layers 420 and 440 by means of a suction force, mechanical force, electrostatic force, sticky substances, adhesives, or the like. This center portion may be of the same size as the wrapper layers 420 and 440.

[0113] Then, the outer layers 410 and 450 and the wr...

tenth embodiment

[0131]FIGS. 27A to 27H show various views of a packaging device, generally designated as 2700, according to the present invention. An article 2702 is trapped between a smaller bag, namely one formed by the sealing of shorter sheets 2704b, 2708b, and a bigger bag, namely one formed by the sealing of longer sheets 2704a, 2708a. Air is introduced into the space between the sheets 2704b, 2708b, and that between the sheets 2704a, 2708a. The inflation pressure of the smaller bag effectively presses the article 2702 against the bigger bag, so as to isolate the article 2702 from the outer sheets 2708a, 2708b. A port 2703 is provided for evacuating the air from between the inner sheets 2704a, 2704b, or for allowing air to escape from the space between the inner sheets 2704a, 2704b during inflation of the smaller bag and the bigger bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com