Cap for liquid container

a liquid container and cap technology, applied in the field of caps, can solve the problems of affecting the use of known caps, affecting the safety of liquid containers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

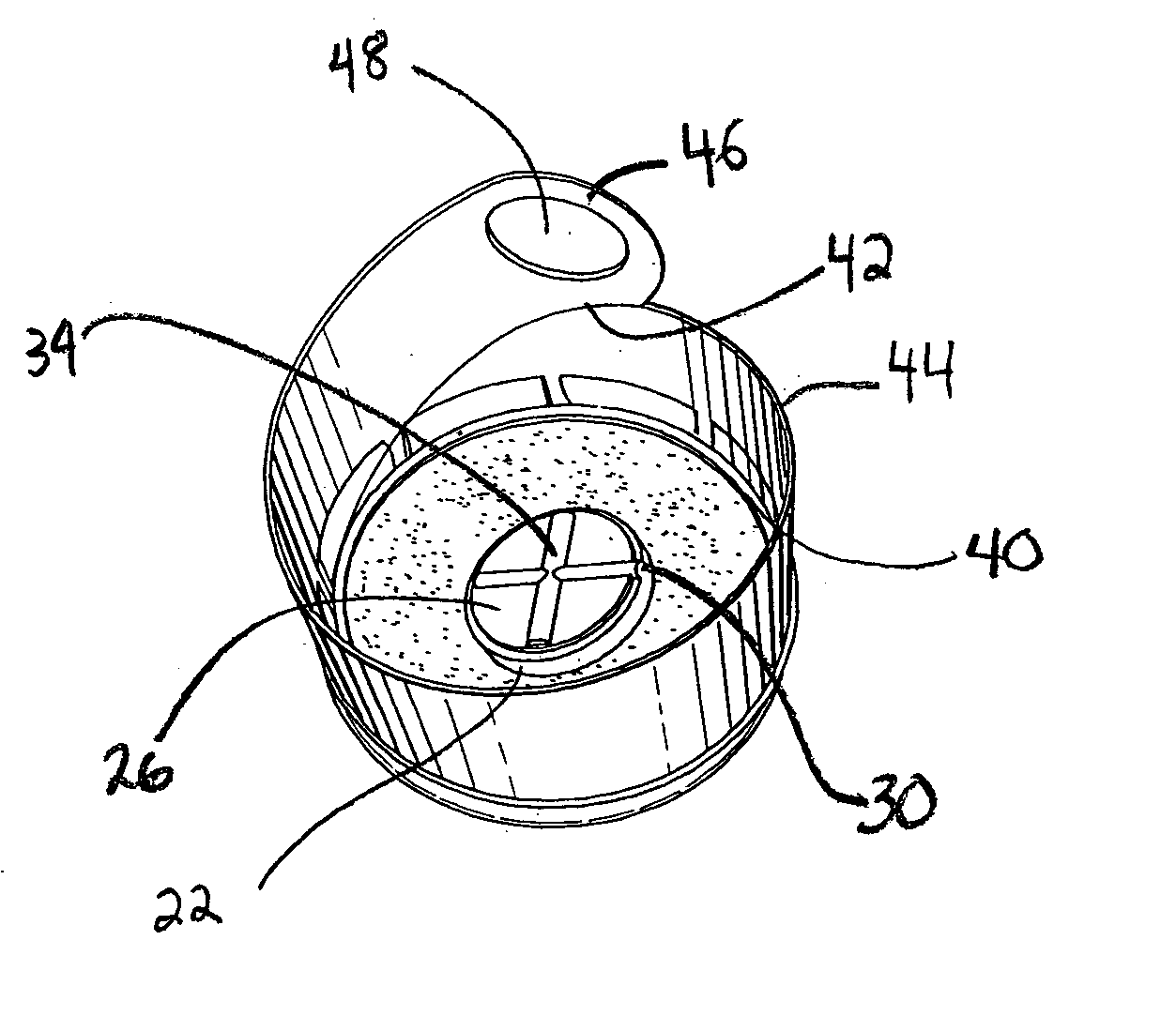

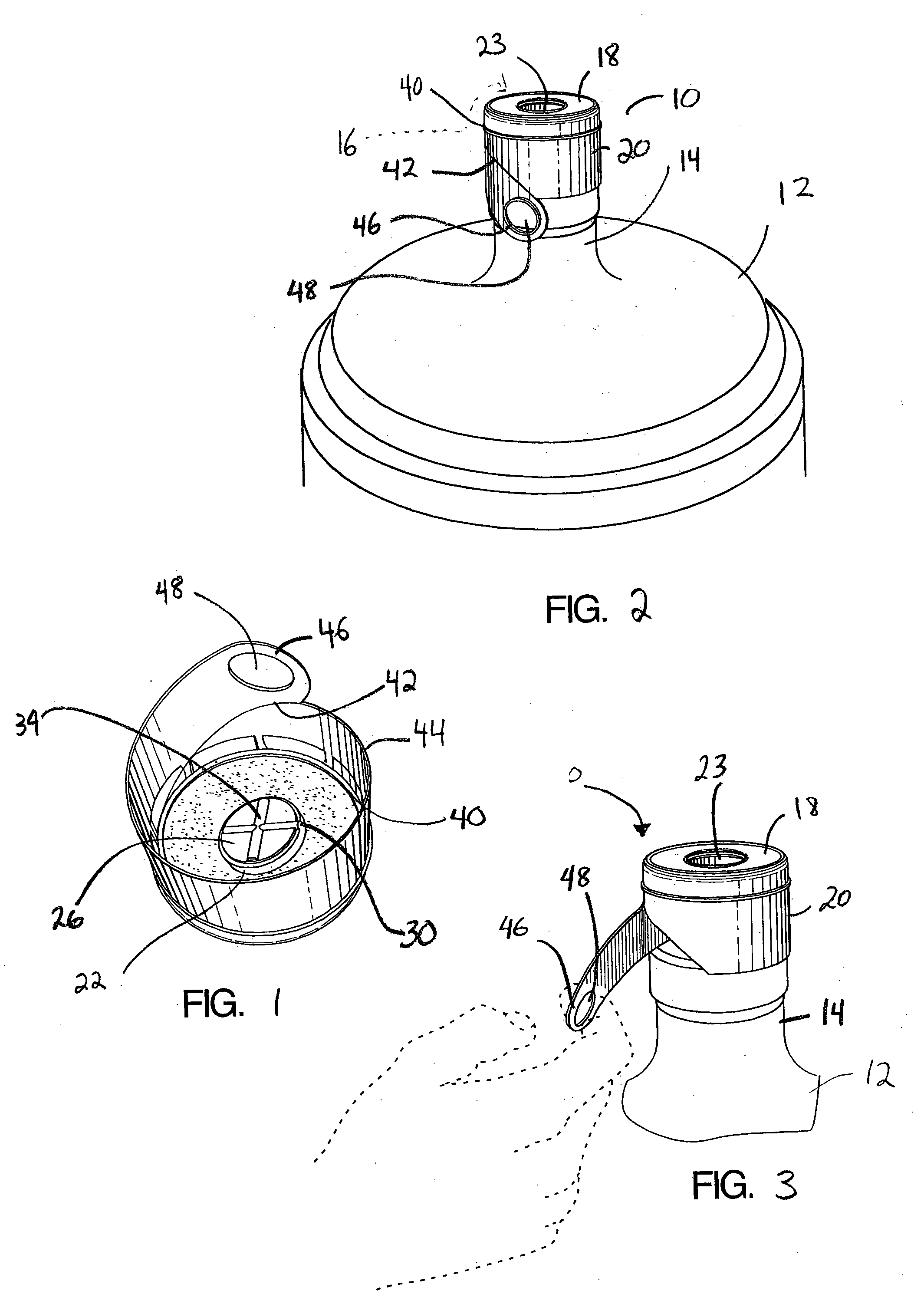

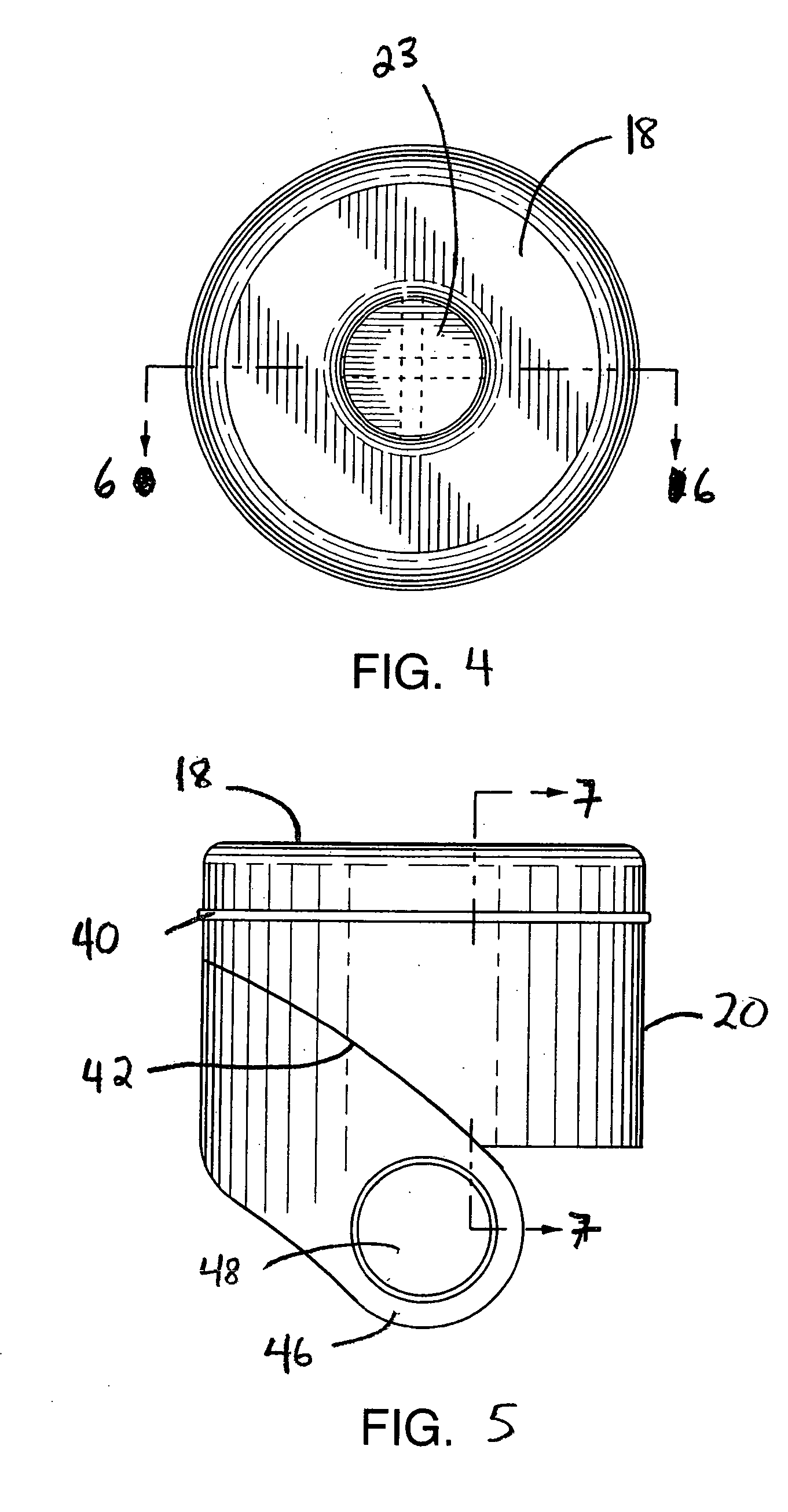

[0029] Shown in FIGS. 1 to 11 is an example embodiment of a one piece plastic cap 10, used with a liquid container 12 having a neck 14 extending to an open mouth 16. The liquid container shown is a common plastic water bottle having an 18.9L capacity, although it should be understood that the cap may adapted for utilization with bottles of various sizes and shapes. The cap 10 comprises an annular base 18, an outer skirt portion 20 which extends upwardly from an outer periphery of the base 18. As can be seen best in FIG. 2, the outer skirt portion 20 and base 18 are adapted for sealing engagement over the neck and mouth 16 of the container 12. A tubular portion 22 defines a central opening 23 in the base 18 and extends from the base upwardly to an upper end 24. When the cap is positioned over the mouth and neck of the container, the tubular portion 22 extends within the mouth 16 of the container. The tubular portion 18 includes a lid 26, which is preferably inclined, covering the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com