Rotary type fluid machine

a fluid machine and rotary technology, applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of insufficient supply and discharge of working medium, restricted axial movement of valve main body,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

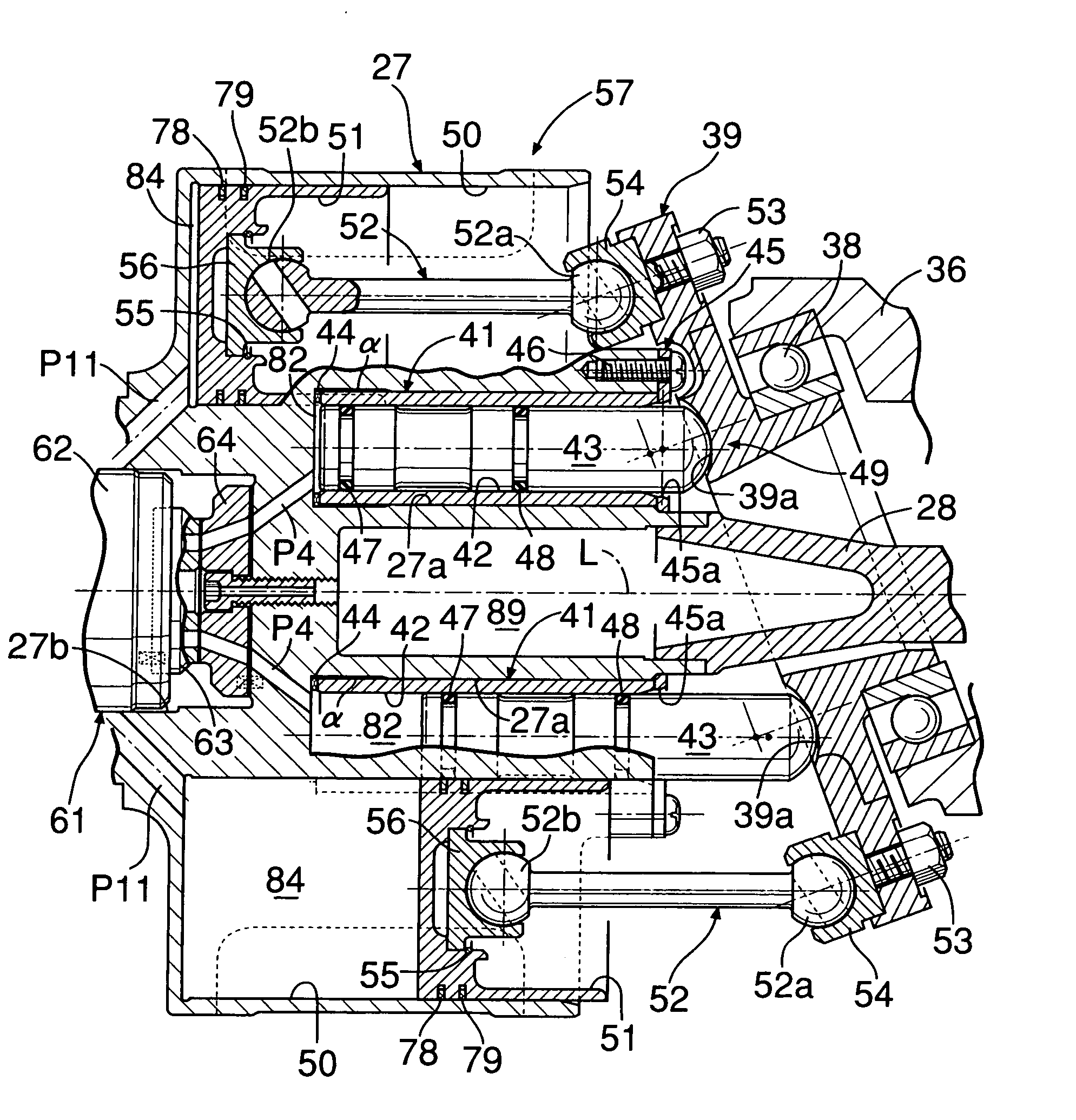

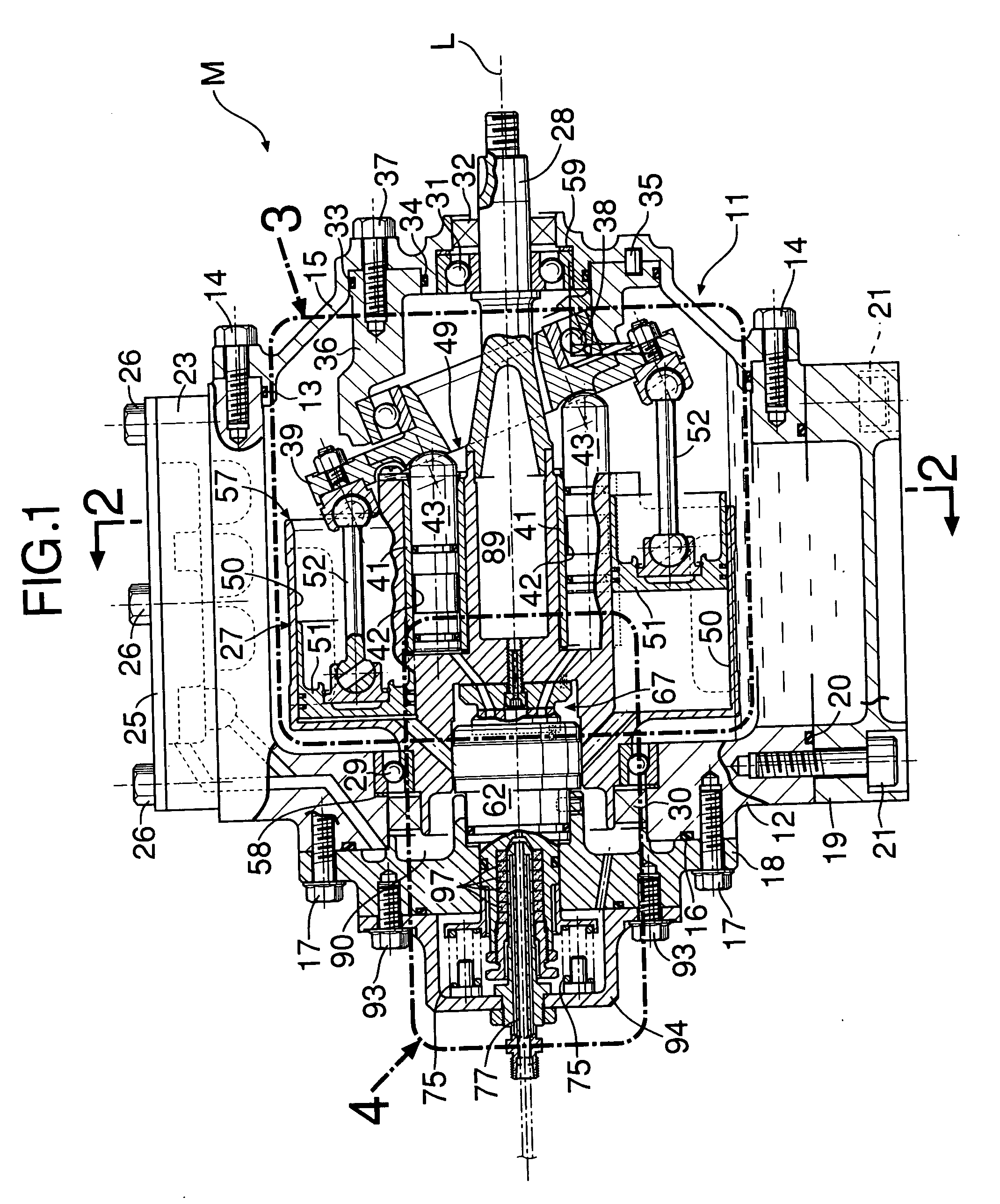

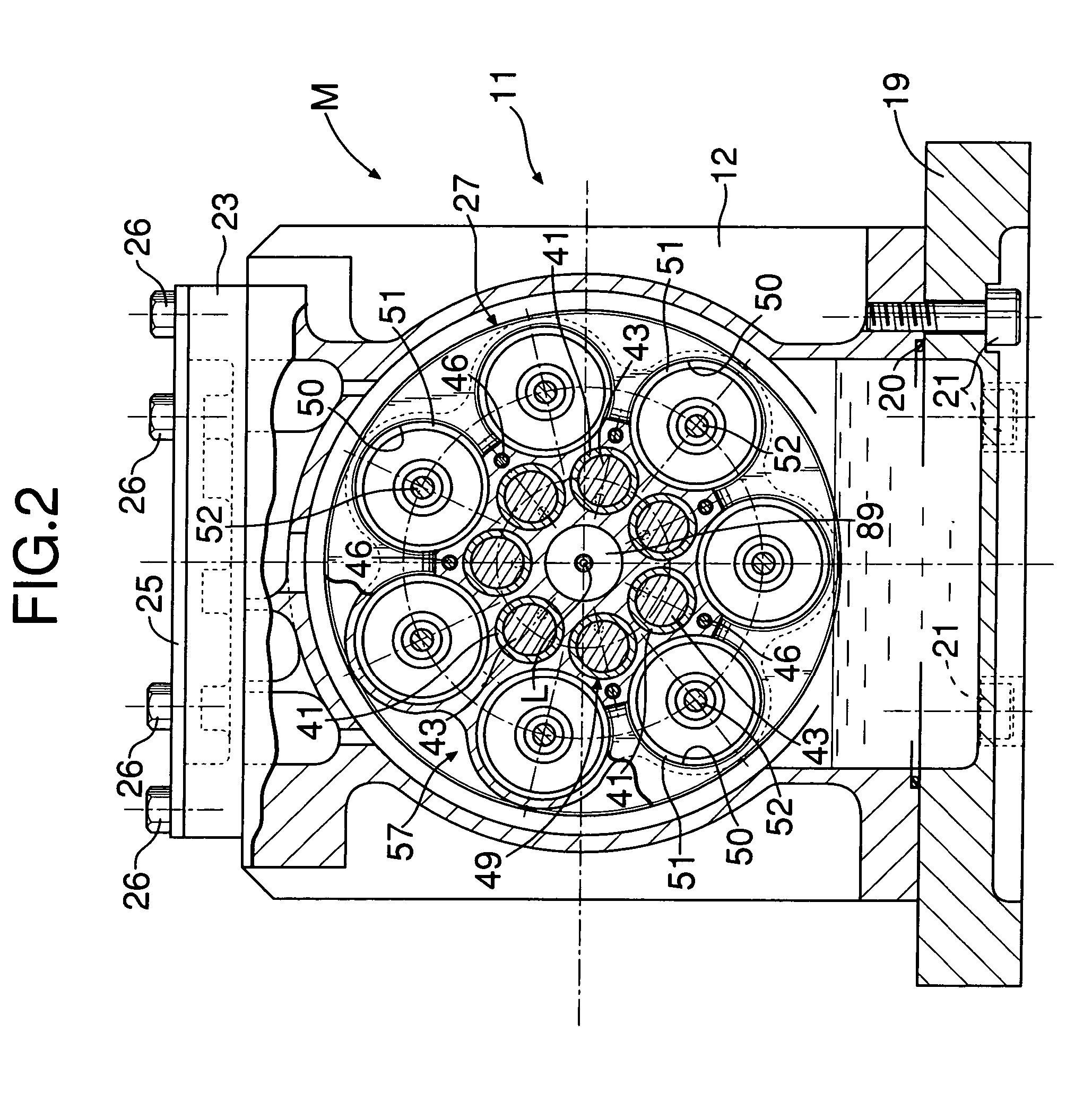

[0015] An embodiment of the present invention is explained below with reference to the attached drawings.

[0016] As shown in FIG. 1 to FIG. 3, a rotary fluid machine of the present invention is, for example, an expander M used in a Rankine cycle system, and the thermal energy and the pressure energy of high-temperature, high-pressure steam as a working medium are converted into mechanical energy and output. A casing 11 of the expander M is formed from a casing main body 12, a front cover 15 fitted via a seal 13 in a front opening of the casing main body 12 and joined thereto via a plurality of bolts 14, and a rear cover 18 fitted via a seal 16 in a rear opening of the casing main body 12 and joined thereto via a plurality of bolts 17. An oil pan 19 abuts against a lower opening of the casing main body 12 via a seal 20 and is joined thereto via a plurality of bolts 21. Furthermore, a breather chamber dividing wall 23 is superimposed on an upper face of the casing main body 12, a brea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com