Positive flow valve

a flow valve and positive technology, applied in the field of medical valves, can solve the problems of clot of blood in patients, troublesome use, and life-threatening malfunctions during use, and achieve the effects of reducing dead space, reliable and repeatable performance, and simple manufacture and us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

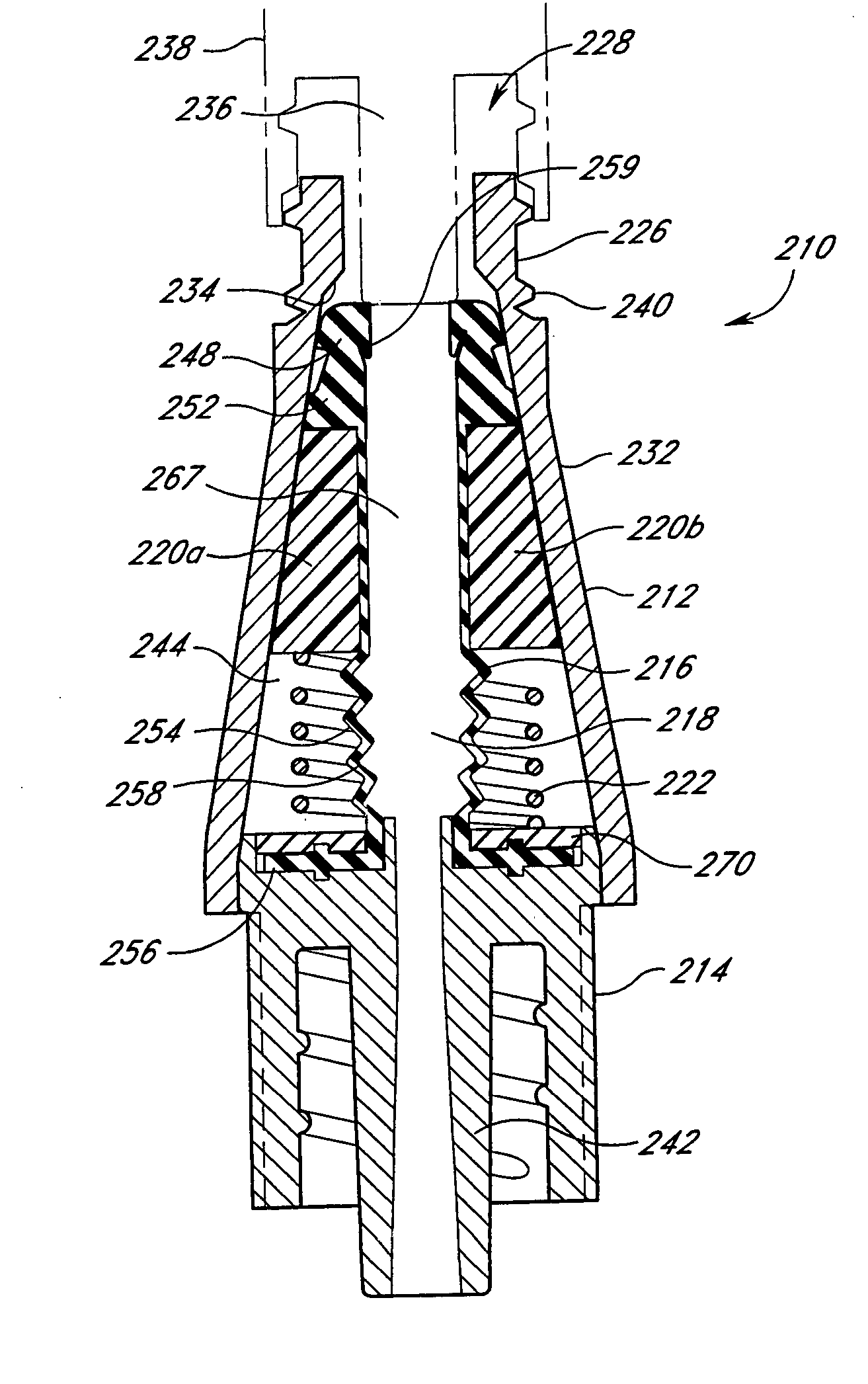

[0051]FIGS. 4 and 5 illustrate a first embodiment of a valve 210 in accordance with the present invention. In general, this valve 210 includes a valve body or housing 212, a support member 214, a seal 216 defining an inner cavity 218, a pair of clam shells 220a and 220b, and a spring 222. These components are assembled, as depicted in FIG. 4, without the need for a spike element. The inner cavity 218 forms an expandable fluid space inside the valve 210. As discussed below, the clam shells 220a / 220b are constructed to cause the volume of the fluid space to expand or increase upon insertion of a medical implement and to contract or decrease upon withdrawal of the medical implement.

[0052] The body or housing 212 has an upper conduit 226 near a proximal end 228, desirably with a circular opening 230 that is adapted to receive the medical implement. A side wall portion 232 is preferably tapered to cooperate with the clam shells 220a / 220b. The body 212 has an upper ledge 234 formed betwe...

second embodiment

[0071] In a second embodiment of the present invention illustrated in FIGS. 6 and 7, the valve 310 includes a valve body or housing 312, a support member 314, a skirt 316, a seal 318, a resilient member 320, and a pair of clam shells 322a / 322b. The housing 312 is desirably similar to the housing 212 of FIG. 4 and has a tapered side wall 324.

[0072] Referring to FIGS. 6 and 7, the second embodiment of the valve 310 has a bell-shaped skirt 316. The skirt 316 has an annular ring 328 which is disposed toward an inner conduit 330 of the support member 314. The skirt 316 creates a shield for the inner conduit 330. This inner conduit 330 is preferably cylindrical in shape and slightly tapered. The inner conduit may be connected to a terminal end of a catheter (not shown), which has an opposite, open end that is generally inserted into a patient. The support member 314 serves as a support and attachment device for the seal 318 by holding the seal 318 in place inside the housing 312.

[0073] ...

third embodiment

[0083] As shown in FIGS. 8 and 9, a third embodiment of the valve 410 of the present invention comprises a valve body or housing 412, a support member 414, a flexible tubing 416, a seal 418, a ring member 420, a pair of clam shells 422a / 422b, and a spring 424. The flexible tubing 416 may be connected to a catheter (not shown) and, together with the seal 418, defines an inner cavity 426. The inner cavity 426 forms an expandable fluid space of the valve 410. The clam shells 422a / 422b desirably are substantially the same as the clam shells 220a / 220b of FIG. 4 and are constructed to cause the fluid space within the valve 410 to increase upon insertion of a medical implement and to decrease upon withdrawal of the medical implement such as a syringe 428 partially shown in phantom in FIG. 9. The housing 412 is desirably similar to the housing 212 of FIG. 4.

[0084] The support member 414 has a hollow center 430 which supports the flexible tubing, and a proximal end 432 which encloses a dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com